3D Printing Safety Tips for Kids

Now that STEM education is being pushed to the forefront, 3D printers are increasingly becoming more common parts of classrooms around the world. This is a welcome development, of course, as 3D printing and other more advanced manufacturing technologies may prove to be vital parts of one’s skill set in the near future.

This development presents an important question – how safe are 3D printers for kids? Can teachers leave students to use 3D printers unsupervised? What safety measures can schools and teachers take to ensure that no untoward incidents happen when kids work with 3D printers?

The hazards of 3D printing

The first step in establishing effective safety practices is to acknowledge that there are inherent hazards to 3D printing. After all, you’re still dealing with a machine with parts that can be heated beyond 200 °C. If you need to teach kids about using 3D printers, then you might as well tell them about the following hazards as well:

Moving parts

There are a lot of moving parts in a 3D printer, almost all of which are driven by the rotation of stepper motors. While these gears are typically inaccessible, it’s much easier for the smaller fingers of children to get caught within these moving parts. It’s good practice for both kids and adults to refrain from touching the moving parts of a 3D printer while printing is ongoing.

Heat

Heat is an important part of 3D printing. It also provides some of its most pervasive hazards. Depending on the filament you’re working with, you might have an extruder temperature that goes as high as 200 to 250 °C. Most 3D printers also have heated print beds that can be heated close to 100 °C. The filament material, of course, is also very hot when it comes out of the extruder nozzle. These are things to watch out for, especially if you’re dealing with a bunch of curious children.

Fumes

When 3D printing, massive heat is applied to the plastic filament materials. Different filaments react in different ways to this heat, but it is much safer to assume that they all release fumes that can range from irritating to downright toxic. Even if you can’t smell anything, the pressure and heat of extrusion also release plastic micro-particles which can result in long-term respiratory problems in humans.

Tools

Aside from the 3D printer itself, completing or finishing 3D printing projects will often involve the use of other tools. Some of these tools are sharp and can still cause injury when used improperly or without proper supervision. If absolutely necessary, you may have to incorporate training for using these tools into your 3D printing class. However, there are tools that are simply too dangerous to leave in the hands of small children.

In listing down these potential hazards, one must always recognize that children are naturally curious and that they might not have developed a sufficient level of motor skills to work with small parts or tools. This means that there must always be a context in the development of safety practices – a different set of rules will be needed between middle schoolers and very young students.

Best 3D printing safety practices for kids

The best safety measure is one that eliminates the hazard completely. If this cannot be done, the next best thing is to reduce the hazard or prevent access to it. These will be our guiding principles in formulating safety measures for kids for 3D printing education.

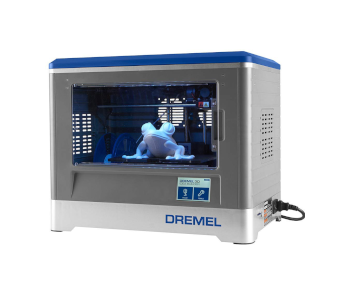

Get a 3D printer with an enclosure

The best way to keep the kids away from the moving or hot parts of a 3D printer is to simply isolate them. Fortunately, a lot of the new desktop-scale 3D printers being sold nowadays come with built-in enclosures. Models from Flashforge, Dremel, and Monoprice are some good options.

These are ideal because they provide protection and isolate the fumes of 3D printing while still allowing students to watch while the 3D printing process unfolds. The physical barrier is highly effective in discouraging kids from poking and prodding the 3D printer while it is still running. You can also set these 3D printers to stop operations as soon as the enclosure or cover is removed, ensuring that no accidents happen even if you’re not actively supervising.

Place warning stickers on parts that can get hot

We realize that warning stickers don’t always work, especially with kids, but it’s still a good idea to have them, nonetheless. They are a good indicator of which parts of the 3D printer get hot. This is a lesson that most people get to learn the hard way, after all.

For best results, we suggest sticking warning labels that are colored bright red. Make sure to use stickers that are actually meant for use in high temperatures, lest you end up with one that gets washed out after just a few weeks.

Inspect the 3D printer before use

A major responsibility of the instructor is to inspect the 3D printers before use to check for any signs of damage. If there are any exposed wires, then it might be a good idea to have the printer repaired first.

Do not touch any parts of a 3D printer while it is running

A good general rule of thumb is to tell your students that under no circumstance should they touch any of the parts of a 3D printer while it is still running except for the control panel. This rule applies to students of all ages as well as to you as the instructor – yes, this is a great opportunity to lead by example.

Avoid crowding around the 3D printer while it is running

Even with all safeguards in place, it is best to enforce a minimum distance between your students and the 3D printer while it is still running. Not only does this help prevent curious fingers from prodding the machine, but it also lessens their exposure to a 3D printer’s harmful fumes. Letting them watch the 3D printer from about five feet away should let them appreciate the process without exposing them to unnecessary hazards.

Do not eat or drink near the 3D printer

It’s a good idea to treat your 3D printing class like you would a chemistry laboratory – everyone should be wearing the proper protective equipment while working, and there should be no eating or drinking in class. Any food or drink has the potential of getting contaminated with the chemical fumes that 3D printing releases. A spilled drink will also be bad news for any electronics and can result in some extreme accidents.

Have students wear goggles, gloves, and respiratory protection

A 3D printing class is an excellent avenue to teach students about general safety. Part of safety is making sure that you are wearing safety equipment appropriate to the activity you are doing. In the case of 3D printing, you will want to wear protection for your eyes, mouth, and nose to avoid chemical inhalation or contamination.

Heat-resistant gloves are also recommended whenever you need to touch potentially hot parts. Since chemical fumes could be anywhere in the classroom, we recommend having all the students wear eye and breathing protection whenever a 3D printer is running as long as they are in the same room. Make sure to use masks that have been specially designed for chemical fumes and not just common particulates.

Print in a well-ventilated area

If you have the option to open windows during printing, then do so. This will help disperse the fumes that 3D printers emit. This is a recommended measure even if you’re using a fully enclosed 3D printer with a dedicated filtered vent. If your room does not have large windows, then you might want to reconsider relocating your class to somewhere with better ventilation.

Only print with PLA

PLA is probably the friendliest filament to work with if you’re teaching 3D printing to kids. It prints at lower temperatures, does not need a heated printing bed, and does not release unpleasant fumes. PLA also isn’t as prone to warping as other 3D printing filaments, making it less likely for your students to go through the frustrating experience of having to start a 3D printing project all over.

Watch out for signs of asthma, allergy, or any flu-like symptoms

There’s a good chance that the kids in your class have not been exposed to the type of chemical fumes that 3D printers release. Even with breathing protection, you will need to keep a close eye on your students and watch out for adverse reactions. If any of your students show signs of difficulty breathing or allergic reactions, then it would be best to have them step outside the room right away. Get in touch with medical personnel if symptoms don’t improve after a few minutes.

As with most safety guidelines, it’s equally important to be receptive to adding or revising the rules as you see fit. Different facilities may require a different set of rules depending on the goals of the course and the available equipment.

Final thoughts

It wasn’t that long ago when ‘shop class’ was a common thing in schools. Learning woodworking is no longer as common nowadays and have been replaced by more tech-oriented fields. With schools opening courses on 3D printing, we feel it our duty to try and provide assistance on how they can keep these classes safe.

The good news is that a lot of desktop-scale 3Dprinters for sale today have been pretty well-designed when it comes to safety. If you can get an enclosed 3D printer with an integrated HEPA filter vent, then that’s already half the battle won.