Laser Cutting Paper – What It Is and How to Make Money with It

Despite digital platforms being the norm nowadays, there is no doubt that old-fashioned paper still has a place in modern products. However, a paper product needs to have a higher level of artistic flair to stand out in today’s more competitive market.

Laser cut paper has been around for a couple of years but remains a relatively rare product. Its visual appeal is undeniable – there’s nothing quite like the level of detail that you can get with laser cutting. How does this technology work and will laser cutting paper be a good business venture?

What is laser cut paper?

Laser cut paper refers to paper products that have been cut or engraved using laser technology. It can create extremely high-precision designs that would not have been possible using other methods. Laser cut paper has been used in greeting cards, signages, calling cards, fashion, custom displays, toys, marketing brochures, and interior architecture.

How does it work?

A laser cutting machine is distinguished by its use of a laser beam as its cutting tool. By concentrating high levels of energy into a narrow beam of light, a laser almost instantly vaporizes the material that it hits. This is a rapid and highly controlled method that works with a huge variety of materials.

The laser cutting process is almost fully automated. The laser cutting machine bases its movements on a pattern determined by a digital file. This could be either a standard CAD file or a graphic done in popular platforms like Adobe Illustrator. File compatibility will depend on the model of the laser cutter. Since you are only working on a paper substrate, the laser cutter will only need to follow a 2D pattern.

Most laser cutting equipment provide versatile settings and options. This means that you do not need to be pigeonholed into laser cutting only paper. By tweaking settings such as laser intensity and movement speed, the same laser cutter can be used to cut or engrave acrylic, fabric, or plastic.

Laser cutting paper is a great way to get into the laser cutting business. Paper products are inexpensive, easy to work with, and appeal to a huge market.

Benefits of laser cutting paper

Let’s be honest – going into the laser cutting business is going to take substantial capital. Even with the cheapest laser cutters available, expect to spend at least $500 on equipment and marketing before you can start earning anything.

Fast

When laser hits a paper substrate, it vaporizes the material almost instantaneously. Couple this with the fact that a laser cutter has minimal moving parts, and you have one of the fastest manufacturing processes ever. This gives laser cutting a huge advantage in handling high-volume orders over more traditional cutting methods.

Very detailed

The resolution of laser cutting is mostly limited by the size of the laser beam. This allows the replication of extremely fine details, even on material as fragile as paper. There is arguably no other cutting technology that can replicate the level of detail possible with a laser cutting machine.

Non-contact

The substrate in laser cutting does not come in contact with any cutting tool. It does not even need to be secured on the build platform. This means that the workpiece suffers no secondary damage from the cutting process and that tools do become as easily deteriorated by wear and tear.

The benefit of this when it comes to operational cost is two-fold. Not only do you enjoy reduced maintenance costs, but profits are also not hurt by too many rejects caused by damage in the production line.

Automated

Once a digital template has been set, a laser cutting process can proceed almost independent of any operator intervention. This speeds up the process, reduces manpower costs, and keeps workers away from the hazards of coming close to cutting tools.

A fully automated process is also less prone to errors. This means that finished products come out with consistent quality. This goes a long way towards gaining customer satisfaction.

Versatile

As mentioned, you do not need to be confined to working with paper when you have a laser cutting machine. Depending on the model, the same machine can work perfectly well with other materials. There is a huge market out there for laser-engraved leather as well as custom-made plastic signages for small businesses. Once you have developed the expertise, you can offer a wide portfolio of products with just a single laser cutting machine.

Earning money with laser cutting paper

1. Buy a good laser cutting machine

A successful laser cutting business will hinge on the quality of the machine that you will buy. There are several different options.

For those with a tight budget, a relatively simple machine like this CNC Laser Engraver from the FoxAlien brand is a satisfactory option. Although there are cheaper options, you will want to get a model with a larger build platform and reliable quality. The downside is that this is basically just a 5W laser head mounted on a movable frame. There is some DIY involved and the whole setup process may not be beginner-friendly.

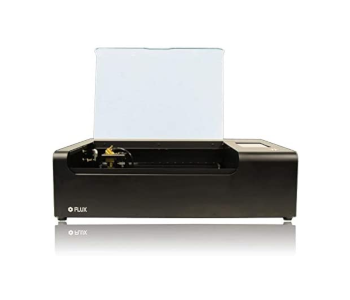

Are you willing to spend a bit more? If so, the fully contained beamo Desktop Laser Cutter and Engraver from Micro-Make is one of the best that money can buy. Compact and fully assembled, the beamo has an intuitive interface and an enclosed and much safer build platform.

A more expensive laser cutter likely has a much simpler work process. In the case of beamo, drawings can be uploaded even by phone. Even hand-drawn designs can be engraved quickly via the built-in Smart Trace software. This convenience is well worth the extra cost of a high-end model.

2. Experiment

Before offering commercial services, make sure that your output is at par with competitors. This means having to practice and experiment with different designs and materials. An extremely detailed design may work well with cardboard but may not be feasibly replicated on standard book paper.

Conversely, you will need to tweak with laser settings so that you can engrave, ablate, or cut through different materials and workpieces. This may be a long and frustrating process but these are the growing pains of going into a new and technology-based venture.

3. Build a portfolio

Finding clients for custom-made paper projects will be hard at first. Not only are there a lot of similar services out there, but you’ll likely also start with a very small portfolio. This emphasizes the need to come up with a large collection of unique products.

At first, you likely will need to do a lot of unpaid work. Ask your family and close friends if they have design ideas for paper products that they need. You can then document these projects for your portfolio. As long as you stick to high quality standards, your products should naturally draw in customers.

4. Update your product line

Don’t forget to update your product page! As customers come along, you will likely work on more unique opportunities. You may not have considered creating a custom-engraved gift box or a 3D puzzle, but these are the types of projects that will challenge you to develop new skills. These are also great chances to expand your portfolio and offer your audience new products.

5. Identify your target market

By the time your business is generating a profit, you should already have an idea of the type of market your products are appealing to. Does your style fit better with corporate clients, or do you get more personal and small-scale projects? Is it better to offer personalized designs or to sell pre-made products? Are you appealing to a specific niche like science fiction or pop culture?

If you have an extremely profitable market, then it makes sense to double down on your efforts to appeal to those types of clients. This does not mean that you should put all your eggs in one basket. Having diverse clients is still fine, but focusing on one market can open doors to more lucrative opportunities.

Final thoughts

Laser cutting technology has been around for a very long time, but it is only recently that it has become recognized as a reliable manufacturing technique. Lasers are a bit more difficult to understand than old-fashioned cutting tools. However, they are unquestionably faster, more precise, and safer than the traditional alternatives.

Starting a business in laser cutting paper should be quite easy, considering how paper is inexpensive and easy to work with. Your creativity and artistic flair will be the keys to stand out in a market that is increasingly becoming competitive.