8 Creative and Interesting Uses of Laser Engraving and Cutting

It seems that more and more artists and craftsmen around the world are starting to realize the potential of laser engraving technology. With laser engraving, intricate art no longer needs to be bound within the corners of a piece of paper or canvas. Even better is the fact that laser engraving can faithfully create details that would be difficult even for a skilled artist.

We have compiled a list of some of the most interesting and creative ways that artists have used laser engraving. Some of these are commercial products, but more are dedicated pieces of art. If you’re wondering what you can do with a laser engraver, then you might just find inspiration here.

1. Laser-cut wooden business card

As old-fashioned as it is, there is nothing quite as professional and succinct as a business card when you need to introduce yourself in a meeting or conference. To make them less boring, there have been a few creative takes in business cards through the years.

With the dawn of laser engraving, we have started to see business cards made with highly intricate engravings. Another novel way of using this technology is by using wooden veneer material for business cards that are either engraved or cut in various creative patterns. These wooden business cards are still thin enough to be flexible but unmistakably stand out from their paper or cardboard counterparts.

The use of very thin wood veneer material is an apt demonstration of how gentle laser marking or engraving is when it’s dialed to the proper parameters. There are a lot of companies nowadays that offer this type of service. From complex lattice-like designs to custom typography, laser engraving will expand what a typical business card can look like.

More than simply making a statement during business meetings, the use of wooden business cards is also a more environmentally sustainable alternative. Instead of relying on industrial printing processes that use solvent-based inks, wooden business cards generate much less waste during manufacturing and are fully biodegradable. A wooden business card isn’t just good for your career – it’s also good for the planet.

2. Custom laser engraved wooden phone case

Your smartphone is something you have in your hand or your pocket practically 24 hours a day every single day. Being an extension of ourselves, it’s not surprising to see phone cases and charms that seem to reflect our personalities. However, there are only so many cheap plastic phone cases out there to choose from. There’s also the fact that these cheap phone cases actually look cheap.

Using laser engraving technology, you can now order a wooden phone case engraved or marked with your customized design. It can have all the trappings of a good quality phone case – textured surface for grip, impact-resistant linings, and openings for the cameras and various ports.

What makes these wooden phone cases unique is that you can have each one marked with custom text, logos, graphics, or even an engraving of your photo. You can even choose from different types of wooden finish, such as maple or cedar.

Laser engraved phone cases are just an example of how laser engraving can bring inexpensive customization to general consumer products. Since a laser engraver only needs a digital file to work with, coming up with one-off designs isn’t more expensive on a per-unit basis than mass-producing the same design. It’s just a business model that works economically and provides a different appeal to customers.

3. Laser-cut 3D puzzles

These puzzles have been around for quite some time and many of us may not have realized that they were made possible by the technology of laser cutting. These are basically puzzles created by intricately cut pieces of wood or cardboard. When they come together, they can create 3D objects such as this waterwheel, American truck, or motorcycle.

What people find most surprising about these puzzles is how inexpensive they are, despite the level of detail and craftmanship that seemingly goes into each product. This is partly because of how rapidly a laser marking machine can make these puzzle pieces regardless of their level of complexity. An entire puzzle set can probably be cut from a single piece of wood or cardboard with minimal waste.

Precision also plays a huge role in how these products are manufactured. Despite the lack of pre-manufactured molds or cutters, the millions of pieces of these puzzles come out with precise shapes and dimensions. This is a huge benefit of laser cutting being a highly automated process with minimal operator intervention.

As a bonus, a wooden puzzle cut with a laser is fully biodegradable. Although we’d like to believe that toys last forever and can be handed down eternally, the truth is that they also have a limited life span. With no paint or other additives, a laser-cut toy makes little impact on the environment when it’s time for it to be disposed of.

4. Laser engraved electric guitar

Professional musicians – especially guitarists – put a lot of stock into looking good when they’re on stage. This is, of course, on top of sounding good. One of the most common ways for guitarists to show off a bit of their personality is to have their guitars customized or handmade.

A good electric guitar is too precious to leave in the hands of an amateur but how about in the working area of a laser engraver? Dean Zelinsky Guitars was one of the first few to pioneer the style with the Dellatera, a guitar with a highly engraved paisley face. Since then, a lot of other brands have popped up offering the service

Just one look at the guitar and one will realize how strong laser engraving is in the area of precision and design freedom. The details in the Dellatera guitar are incredibly small and complex and would probably be a challenge even for an experienced craftsman. Other engraved guitars feature more modern designs, exhibiting a fusion of the old and the new.

Guitars are highly valued instruments for musicians, so even the smallest risk of them getting damaged can be a daunting though. Fortunately, laser marking is a non-contact technology that significantly lowers this risk. Since there is no mechanical force applied to the guitars during the process, they don’t even have to be mounted in place.

5. Laser engraved rolling pins

While most laser engraved products have designs for purely aesthetic purpose, there are a few rare products which use engravings to enhance functions. These laser engraved rolling pins are good examples of such a product.

Using laser engraving, the standard rolling pin has been upgraded with intricately detailed designs that can be transferred to the dough while rolling. These are great for adding flair or a festive mood to your baked products.

As with the laser cut puzzles, it’s pretty surprising that these rolling pins with laser-cut designs are only just slightly more expensive than the plain old rolling pins. Again, laser cutting is a surprisingly economical way to reproduce a huge number of intricately designed products. Quality is also top-notch with laser engraving – you would not want to bake cookies with distorted trees or snowmen.

Unlike other engraving methods, the cuts made by lasers are incredibly clean. This is important for cooking tools like rolling pins, as small irregularities can serve as pockets that promote bacterial growth. As a testament to how food-safe laser marking technology is, it has even been used to create marks directly on food and medicine.

A rolling pin is a good demonstration of how laser engraving can work even on circular surfaces. In laser engraving, the process is essentially the same regardless of the shape of the workpiece. This trait further expands the possibilities of what can be done with laser engraving.

6. Pop up greeting cards

Greeting cards are always nice but greeting cards with pop-up designs are undoubtedly better. With laser cutting, you can take that sequence one level higher and give laser-cut pop-up greeting cards. These may seem like your usual pop-up greeting cards except that they come with designs so intricate that they can only be reliably created using laser cutting technology.

Lovepop Cards is one of the more popular brands in this category, thanks in no small part to their exposure and successful pitch in Shark Tank. Their designs highlight the huge possibility of what can be done with laser cutting. From flower bouquets to cherry blossom trees, the designs of Lovepop truly stand out and showcase the design freedom of using laser cutting.

Nowadays, there are a lot of other brands that offer similar pop-up greeting cards. Design quality likely varies from one brand to another, but a lot of them pretty impressive. Paper being such a fragile material, the non-contact characteristic of laser cutting likely plays a big role in the success of this whole idea.

With laser cut greeting cards becoming more common, brands like Lovepop may revolutionize the whole greeting card industry. In the right hands, laser technology can be a truly disruptive force in many unlikely fields.

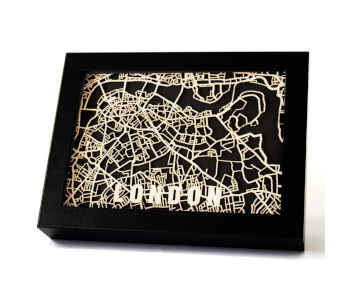

7. Laser-cut map art

Have you ever gone on vacation somewhere and just fell in love with the place? This is a familiar feeling for a lot of people and one that makes you long to take home a piece of the place with you. We find that one of the more unique ways to do this is by displaying a piece of map art in your home, such as this one for London.

Map art basically takes the street map of a place from any open source and uses this as a pattern for laser cutting. The result is a single piece of paper cut into very thin strips representing the streets for that place. These strips crisscross with each other within very small spaces. The craftsmanship of wall art is impressive and one that would probably be difficult (and expensive) for a person to do by hand.

The use of laser cutting makes street map art quite affordable and accessible. Since laser cutting only requires a digital file as a reference, there’s basically no skill involved save for being able to operate the laser cutting machine. Some would argue that this removes the “soul” of making art, but we’d like to think of it as making art in an alternative yet equally valid method.

Even in an industrial setting, the use of a laser engraving machine requires much less skill compared to more traditional equipment like mills and lathes. Less training means more productive time, making laser cutting and engraving a more economical technology in the long run.

8. Laser-cut jewelry

Design is a huge part of selecting which jewelry to buy. We’ve come a long way since the days when practically all jewelry was handmade. Nowadays, you can buy earrings or bracelets with intricate laser-cut designs that are a lot cheaper.

If you search for laser cut jewelry, you will likely find that most of them are made of wood. There’s nothing wrong with wood jewelry, as they are very budget-friendly and feature a lot of interesting designs. A few good examples include these Bohemian-inspired teardrop earrings and this set of wooden filigree pendants.

However, laser-cut jewelry isn’t restricted to working with wood. If you prefer wearing gold or silver, then you might want to take a look at these laser cut sterling silver earrings or these gold-plated silver hoop earrings. The designs for these are so amazingly intricate that they cannot be conceivably created using traditional hand methods.

The best thing about laser cutting is that it helps keep the price of these pieces of jewelry down. The manufacturing process is essentially the same between wood or silver – it only takes minor tooling changes and changing of laser parameters. If you’ve always wanted intricate jewelry but can’t afford it, then laser cutting technology may be exactly what you’ve been waiting for.

Final products

Laser technology has been around for a really long time but is yet to hit the mainstream in manufacturing technology. While there are a ton of hurdles for laser technology to become more common, the fact that more and more people are finding ways to use lasers creatively should help its acceptance.

This list of interesting ways in which laser cutting and engraving are used today serve to highlight all of its benefits in terms of automation, customization, precision, and economics. If used right, lasers can create truly unique products, a lot of which have never existed before. If you had a laser cutting machine, what are some of the creative ways that you would use it?

Always looking for more uses of Laser Engraving