Metallic Filaments: Properties, How to Use Them, and Best Brands

When it comes to specialty filaments, we find that people have become especially curious about metallic filaments. Perhaps you have seen custom 3D prints that appear like they are made of bronze or stainless steel. More than the aesthetics of the products, people are curious about how these metallic filaments work and what else they are capable of. If you are curious, then you have come to the right place as we will tell you everything you need to know about metal filaments.

What are metallic filaments?

Similar to magnetic filaments, metallic filaments are made by infusing PLA with very fine metal powders. These metal powders may vary by brand. Right now, metallic filaments are available that have brass, bronze, copper, or stainless steel powders. The ratio of PLA to the metal powder vary by the brand and product, but usually falls in the neighborhood of 80% metal to 20% plastic.

The addition of metal powders gives the filaments a much higher density than the standard plastic filaments. This means that prints made from metallic filaments are much heavier compared to prints made from plastic, despite using the same amount of material.

We are, of course, talking about metal printing that can be done at home using your desktop 3D printers and composite metal filaments. Full metal 3D printing is a well-established industry, with companies like EOS and Stratasys leading the way. The limitation of full metal 3D printing, as you would expect, is the prohibitively high costs associated with it. Professional metal 3D printers, capable of reaching printing temperatures of up to 1,400 °C, will set you back a nice $500,000.

We like to keep it simple and practical, so let’s stick with what we know best. Composite metal filaments allow us to make prints with the look and feel of full metal prints, but at a much more affordable price tag. Keep in mind that there are filaments out in the market that have metallic coloring added to the filament. It is important to keep this distinction, as metallic-colored filaments have no metal powder infused into them.

What are the benefits of using metallic filaments?

The number one reason that most people go into using metallic filaments is the superior aesthetics of the finished product. With some finishing, metallic prints can have the luster of real metal, despite being a composite material. With its high density, metallic prints have a nice heft that you cannot achieve with other filament materials.

Similar to prints made with other composite materials, metal prints are quite rigid, with little to no flexibility. They are somewhat durable, although not nearly as durable as full metal prints.

Metallic filaments do not require very high printing temperatures, so your standard desktop 3D printer should be more than enough. Metallic prints are not very prone to shrinkage or warping, so cooling your prints too quickly should not be an issue. This does not mean that printing using metallic filaments is a simple matter. It has its own challenges, that we will discuss later.

How do you work with metallic filaments?

The printing temperature for metallic filaments may vary based on the brand and type of filament that you are using. As we have mentioned, composite metal filaments may be fused with different metal types, each of which has its own heat conductivity characteristics. A range of 190 to 220 °C should work for most materials, but it should be best follow the instructions of the manufacturer.

Metal filaments suffer from the same disadvantage as other fused filaments, in that the metal powder component of the filament may be abrasive to soft materials. If your 3D printer uses a stock brass nozzle in its hot end, then it may be time for you to invest in more durable, wear-resistant nozzle. Another way to prevent abrasion of your nozzle is to use a higher sized nozzle. We have gotten good results with nozzle sizes of 0.5mm to 0.6mm when using metallic filaments. Always check your nozzles for signs of abrasion, as a worn down nozzle will result in a poor quality print.

As we have mentioned, metallic prints are not very prone to warping, so a heated bed is not necessary when printing with metallic filaments. However, if you are already using a heated bed, a pretty low temperature of 45 to 60 °C should do well enough. Any method of bed adhesion that works well with PLA should work just as well with a PLA-based metallic filament. We recommend standard blue painters’ tape if you are using a non-heated bed. If you are using a heated bed, a bit of glue stick applied directly to the glass surface should do the trick.

The thermal conductivity of the metal powder fused into the filament allows the filament to heat up faster as it enters the hot end. The benefit of this characteristic is that it allows you to print at higher speeds compared to pure plastic filaments. Of course, this thermal conductivity will vary depending on the type of metal fused into the filament, so it will be best to ask your manufacturer. We have had good results printing metallic filaments with speeds of up to 80mm/s, but we suggest starting at around 50mm/s and working your way up.

Being able to heat up faster means the metallic filaments are also able to cool down faster. This mitigates some of the problems you may encounter when using metallic filaments (as we shall discuss later), but we still recommend using a cooling fan to further speed up the cooling process. Metal prints practically do not warp, so you may use your cooling fan at its maximum setting.

Retractions can also be a problem when working with metallic filaments, as with other fused filaments. Keeping the filament in the melt chamber during retraction can be especially complicated, resulting in sections with blobs where the extruder starts and stops the extruding process. You may need to set your printing software to minimize retractions during printing, or choose a design that requires minimal retractions.

A lot of people have come up with creative ways to finish a metallic print. One of the more common ones is to use a coarse steel wool to lightly polish the surface of the print. This exposes the metal powder, giving your print the characteristic metallic luster. You may apply a thin coat of spray paint or metal polish to give your print a more finished and polished look. If you come up with other post-processing methods, then leave a comment below.

Are there limitations in using metallic filaments?

If you have tried shopping around for metallic filaments, you would probably have noticed that they are usually more expensive than standard plastic filaments. They are not so expensive to be prohibitive, but you will want to minimize waste when using them.

Prints made from metallic prints are rigid, but can be notoriously brittle. Since the metals are only present in powder form, they lend no structural support whatsoever to the final print. The lack of flexibility may mean that metallic prints are even less durable than prints made from standard PLA. Our advise is to not make metallic prints for applications that you expect to go through sustained force or sudden impact.

As we have mentioned, there is no ‘one size fits all’ printer setting that can be used when working with metallic filaments. Different metal materials and different mixing ratios means that printing with metallic filaments may take more than a little experimentation and tweaking before you get the results you are satisfied with.

The metallic filaments are both heavy and brittle. You will have to ensure that the filament path from the spool to the nozzle does not have any sharp turns, or your filament will break mid-way. The parts printed using metallic filaments are probably heavier than you would expect, and they have very poor bridging characteristics. Having a strong cooling fan can help mitigate this limitation, as the material strengthens while being cooled. If you are printing a design that has several overhangs (even small ones), you might have to consider adding support structures. We recommend PVA for your support material, as it easily dissolved in water.

Lastly, you will probably have to invest on a new hot-end nozzle to print with metal filaments. This is not a foolproof solution, and even a wear-resistant nozzle might degrade over some time.

What are the best brands of metallic filaments available today?

Be careful not to confuse metallic-colored filaments with actual metal-fused filaments. Metal-fused filaments are usually more expensive, and come with a dull, opaque look. We have compiled below a list of the most common and reliable metallic filament brands available in the market.

Up first is GizmoDorks, known for having a very wide range of filament products. GizmoDorks sells both Copper Fill and Bronze Fill filaments, both of which are available in 1.75mm size. Their product is perfect for those who want to try out metallic filaments, as they sell starter-sized 200g spools. Their metal filled filaments are also available in 1kg spools for those who are a bit more committed.

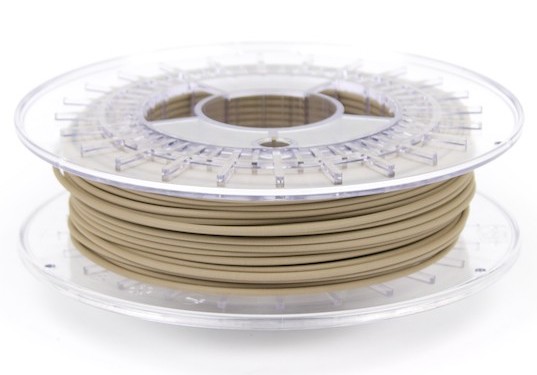

ColorFabb has 3 metallic filament products available today: CopperFill, BronzeFill, and BrassFill. With a greater range of metal types, you have more room to be creative. Their metallic filaments are available in both 1.75mm and 3.00mm sizes. You may also choose from spool sizes of 0.75kg and 1.5kg.

Proto-Pasta has 2 options for metallic filaments: the Copper Metal Composite, and the Polishable Stainless Steel Spool, both available in 1.75mm size and 500g spools.

SainSmart has a set of 3 choices for your metallic printing needs: bronze, copper, and aluminum. Although not as well-known as the other brands mentioned here, their products have received consistently good reviews and feedback. Their metal-filled filaments are available in 1.75mm sizes and 0.5kg spools.

The Roundup

| Material | Metallic Filament |

| Properties | – Metallic sheen and luster – Rigid but brittle – Has a wide range of metallic material options (stainless steel, aluminum, bronze, brass, etc.) |

| Applications | – Customized jewelry and trinkets – Home fixtures – Prototypes and display materials |

| Recommended printing temperature | 190 to 220 °C, but may vary depending on the filament brand |

| Recommended bed temperature | Heated bed not necessary; 45 to 60 °C if using a heated bed |

| Adhesion | Blue painter’s tape if using a non-heated bed; standard gluestick applied directly to the glass surface if using a heated bed |

| Printing speed | 50mm/s to 80mm/s; may vary based on filament brand |

| Cooling | Recommended cooling fan set at maximum |

In terms of aesthetics, there is probably no other specialty filament that can rival that of the composite metallic filaments. With some brilliant engineering, users can now produce customized prints that have the look and the finish of real metal. Don’t expect your composite metal prints to be as durable as the real thing, but they can make nice little models and displays. Custom metal prints are perfect for making your own jewelry, gifts, and small trinkets.

Printing using metallic filaments can be quite challenging because of the variability in printer settings that different filament materials and brands require. However, there are small spool sizes available in the market that will allow you try out printing with metallic materials without a large financial commitment.