All About Nylon (PA) Plastic

Nylon (PA) is a silky thermoplastic material. It can be melt-processed into fibers, films, and other shapes. Nylon is used in a wide variety of materials because it is long lasting, resistant to chemicals, very strong, and easily washable. It can also withstand a fair amount of abrasion and moisture absorption. Applications in a high-temperature environment also tend to use nylon because it offers a high-temperature resilience. One example of such use is nylon in the engine compartment of vehicles.

Being a thermoplastic material, nylon has a melting point of 220oC. It can be heated to that temperature, cooled, and then reheated again without any significant degradation. The ability of nylon to liquefy at 220oC makes it a good fit for injection molding. Nylon interestingly finds use in moving parts like gears and bearings because it has low-friction properties. Nylon may not be the most slippery of all the plastics commercially available, but it is still good enough to be used with parts where there is a lot of wear and movement.

History of Nylon

The famous American company DuPont first produced Nylon in 1935. After World War 1, DuPont had produced a material called Rayon, and that experience was crucial in helping it produce Nylon. In February of 1935, Wallace Carothers produced what is now known as Nylon 6,6 at DuPont’s research facility. DuPont subsequently obtained a patent for nylon three years later in September 1938. It was the result of an 8-year process which first started in 1930 when DuPont actually started the project to create Nylon.

In 1938, a German scientist named Paul Schlack of the company IG Fabran also produced nylon using a different method to the one used by Carothers. His nylon was known as nylon 6.

After its discovery, nylon was marketed at trade fairs and expos. It also found favor with the American public because it was positioned to be an alternative to silk imports from Japan. Reduction in any kind of imports from Japan was considered to be good at that time. Nylon stockings were one of the most popular products after its initial discovery.

Nylon use has grown significantly over time and more products are being made using nylon than ever before. Today, the market for nylon 6 and nylon 66 exceeds USD 25 billion.

Manufacturing of Nylon

Nylon is formed as a result of a reaction between difunctional monomers which contain equal parts of amine (NH2) and carboxylic acid (COOH). Another way of producing nylon is diamine (2 times NH2) with dicarboxylic acid (2 times COOH). In both these processes, a chain of monomers is formed in an “ABAB” structure. Nylon is a copolymer, with each monomer in the chain having the same reactive group on both ends.

Nylon produced from biomass has a more biodegradable nature. Most of the nylons are semi-crystalline and have a high degree of thermal and chemical resistance. Nylon also has a tendency to absorb moisture from the surroundings until an equilibrium level is reached. This presence of moisture tends to increase the impact resistance and flexibility of the material. There are different types of nylon which can be produced to give a wide variety of physical properties such as specific gravity and melting points.

Different grades of Nylon

Different types of nylon are denoted by different “nylon numbers”. Nylon is available as a homopolymer, copolymer, and reinforced nylon. A single nylon number denotes a homopolymer while two digits denote the use of multiple monomers in combination. A slash suggests that more than one comonomer groups are used in combination to produce the material. Nylon can also be mixed and combined with other engineering plastics. Certain blends of nylon are used in specific industries. Some of the types of nylon are:

- Nylon 6 – This is what Paul Schlack created in Germany. Quite popular these days.

- Nylon 66 – This is a very popular form of nylon, created by DuPont.

- Nylon 510 – This type of nylon is believed to have been studied by Carothers even before he focused on nylon 66.

- Nylon 6/66 – This one is a copolymer also known as DuPont Zytel.

Applications of Nylon

Automotive: Nylon is used to make door handles of vehicles. This is because properties required for them are good appearance, paintability, and good UV resistance. It also has to be stiff and tough. Another part in cars made using nylon is the radiator grill. Nylon is even used in tires.

Electrical: Nylon is used to make low-voltage switch gears. Switch gears include products like relays, fuses, circuit breakers, switches, and contactors.

Home improvement: Nylon 6 and 66 are used as fibers in carpets. It is also used in furniture, especially at the points of contact.

Currency paper: US currency notes use a high-grade paper as its raw material. This high-grade paper uses nylon.

Military use: Parachutes, tents, and ropes are made using nylon. During World War II, this was the case in order to replace silk imports.

Domestic/Consumer Goods: Nylon is used to make hooks and combs. Toothbrushes, string trimmers, and fishing lines are also made using nylon filaments. Inline skates and ski bindings also use nylon. Guitar strings sometimes contain nylon as well.

Apparel: Stockings, gowns, dresses, weather-repellent clothing are all made using nylon. Athletic clothing uses nylon a lot because it wicks moisture away from the body. It fits the body tightly and is used to make the modern compression gear type of athletic apparel. Nylon, being a synthetic material, costs less than natural materials.

Food packaging: Nylon is used to make food packaging films. Meat wrappings and sausage sheaths are made using nylon. Oven bags are also made using nylon because the material has high-temperature resistance.

Nylon Prototypes using CNC and 3D printer machines

CNC machines

Nylon is a material which can be turned into sheet stock by heating and melting. Sheet stock form is useful with CNC machines as it works well with a machining process that involves a mill or lathe. Nylon has a reasonably high stiffness along with toughness, all of which translates into great machinability. Nylon 6 and Nylon 66 are commonly used with CNC machines for making prototypes. Production costs can also be kept low as nylon is one of the cheapest plastics available commercially.

3D Printing

Nylon is also available in a filament form which can be used with 3D printers to create prototypes using computer-aided design files. As nylon is a thermoplastic which can be melted and then cooled without degradation, it is used with 3D printers. The 3D printer basically heats the nylon filament and then deposits it according to the design of the prototype. Normally, the color of nylon is off-white, black, or white. However, as it can be dyed using various colors, nylon can be used with a 3D printer to achieve all kinds of designs and looks that a prototype needs to have.

Injection Molding

Nylon can also be used to make prototypes using the injection molding process. The nylon that is used for injection molding is often filled with a certain amount of glass fiber. Doing this increases the tensile strength of the nylon material. Without the increased tensile strength, the nylon prototype might bend or break. Normally the proportion of glass fiber mixed varies between 10% and 40%.

Disadvantages of Nylon

- In spite of having a high melting point, nylon does not perform very well when exposed to an open flame.

- Nylon is flammable and burns easily when exposed to open fire. Hence, a flame retardant needs to be added to nylon when it is being used in an application that involves exposure to open flame or fire.

- Nylon gets affected by UV rays that may be present in sunlight. Hence, for certain applications where sunlight is involved, a UV stabilizer needs to be added to the nylon raw material before any manufacturing of the product.

- Nylon gives out toxic fumes containing hydrogen cyanide when it is burned in a fire. That is not good from an environmental standpoint. Incineration of nylon is also expensive and hence most of the nylon often finds itself in garbage dumps. It takes 30 to 40 years to decay and decompose.

Properties and Specs

| Property Type | Detail |

| Scientific Name | Polyamide (PA) |

| Resin Identification Code | Other (7) |

| Chemical Formula | [NH−(CH2)5−CO]n |

| Tensile Strength | 76 MPa (11000 PSI) |

| Dielectric Constant | 3.4 |

| Specific Gravity | 1.13 |

| Melting Temperature | 220oC |

| Flexural Strength | 110 MPa (16000 PSI) |

| Maximum Continuous Use Temperature | 150oC to 185oC |

| Shrink Rate | 1.3 – 1.7% (0.013 – 0.017 in/in) |

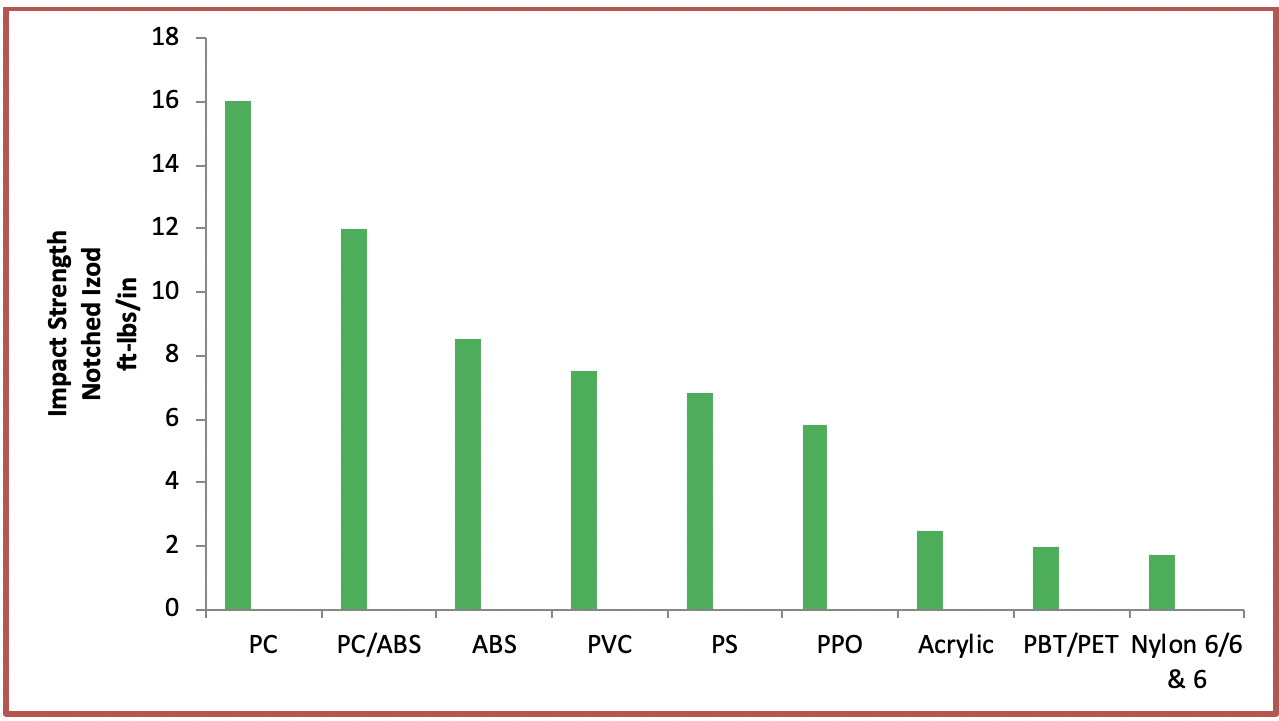

| Notched Impact Strength | 5 – 13 Kj/m2 |

| Elongation at break | 60% (110% for nylon 6/66) |

| Rockwell Hardness | M80 (nylon 6), M90 (nylon 6/6) |

| Poisson’s Ratio (v) | 0.39 to 0.41 |

| Heat Deflection Temperature | 160oC at 66 PSI |

| Injection Mold Temperature (Typical) | 54oC to 93oC |

| Chemical | Resistance Level |

| Acid (Concentrated) | Poor |

| Acid (Dilute) | Good |

| Alcohol | Poor |

| Alkalis | Average |

| Aromatic Hydrocarbons | Poor |

| Greases and Oils | Good |

| Halogenated Hydrocarbons | Average |

| Halogens | Poor |

| Ketones | Good |