PETG vs PLA: Which One Is Better for 3D Printing?

PLA may be considered one of the most popular 3D printing filaments used today, but it is by no means perfect. While it’s very easy to handle, PLA is not particularly known as a strong or durable material.

In recent years, PETG has been gaining a following as an alternative to both PLA and ABS. What does PETG offer that makes it competitive with PLA? How do the two compare is there a choice that is clearly superior?

PLA

The basics

PLA stands for polylactic acid, a polymer made of lactide monomers. A distinguishing characteristic of PLA is that it is made from sustainable sources and breaks down into environment-friendly lactide constituents. This has given PLA the distinction of being the second most heavily used bioplastic in the world.

Although the claims of PLA being ‘biodegradable’ have been put into question in recent years, it’s still considered a lesser evil compared to petroleum-derived plastics. The raw material used to manufacture PLA comes from plant matter, mostly corn. Perhaps it is then more accurate to describe PLA as sustainable rather than biodegradable.

In the field of 3D printing, most indicators state that PLA is the most widely used filament material. Aside from its appeal as a sustainable plastic, PLA is very inexpensive and easy to work with. It prints at low temperatures, is not prone to warping, and does not emit unpleasant fumes. These characteristics have made PLA very popular for both beginners and experienced users of 3D printers.

Pros and cons

PROS

Cheap

Right now, you can buy a 1-kilogram spool of PLA filament for about $20. Because of how popular PLA filament has become, any 3D filament brand worth their salt probably has a lineup of different PLA filaments. This richness in supply has made PLA one of the cheapest 3D printing filaments available today. Just make sure to get your PLA filament from a reputable manufacturer like Hatchbox or Gizmo Dorks.

Easy to work with

There are about half a dozen things about PLA that make it ideal for beginners. It prints at low temperatures, has no bed adhesion issues, does not require a heated bed, does not warp, and does not produce unpleasant fumes. This eliminates most of the issues encountered in 3D printing and makes the whole process so much simpler.

This also makes PLA the ideal filament for basic 3D printers with no fancy features. You don’t need a heated print bed or a bed enclosure. Applying a simple adhesive with a glue stick is enough to make sure that the base layer sticks to the print bed. Even expert users keep a PLA spool around in case they want to do quick trial prints with little complexity.

Sustainable option

PLA is manufactured from lactide or lactic acid monomers, which is then produced via fermentation of starch from plant matter. This makes PLA the only 3D printing material that comes from sustainable raw material. This has become a huge selling point for PLA, especially among the more environment-conscious users.

On the other side of this equation, PLA can be broken down back to its lactide or lactic acid constituents. These are substances that are considered safe for humans, animals, and the environment.

However, it bears mentioning that carefully controlled conditions are needed for the biodegradation of PLA. Basically, you still can’t bury them in the ground or throw them into the sea and expect them to be reduced to nothing within the next one or two years. It’s best to send your PLA waste to a suitable waste disposal facility.

Wider selection

PLA is so popular and easy to manufacture that there is now a virtually endless array of them out there with different flavors from different brands.

Aside from a huge selection of colors, we have unique varieties like the PLA+ from Overture, the PLA/PHA filament from ColorFabb, and the HTPLA line from Proto-pasta. These PLA blends deliver high-performance characteristics such as higher toughness, enhanced heat stability, or more flexible post-processing options.

Taking it one step further are composite filaments. These are filaments designed to simulate the look of materials not normally used in 3D printing, such as metal or wood. The majority of these composite filaments are made by mixing solid particles within a PLA matrix, allowing them to take on the ease-of-use of standard PLA.

This bundle of Marble PLA, Bronze PLA, and wood filament by AMOLEN is a great way to get a taste of printing with PLA composite filaments.

Support material compatibility

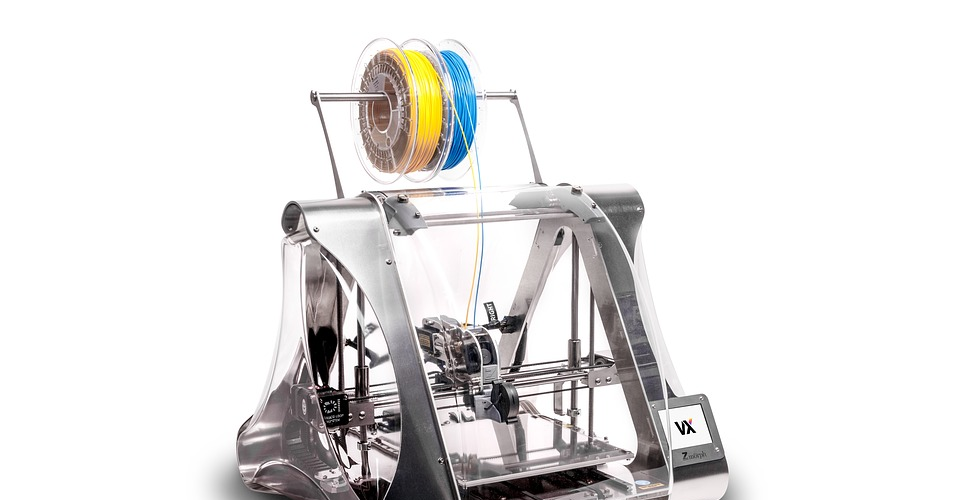

Support structures are almost unavoidable in 3D printing, which is unfortunate considering how much of a headache they are to remove. The advantage of printing with PLA is that you have the option of printing supports with Polyvinyl alcohol or PVA (given that you use a dual-extruder printer).

PVA is a polymer that is completely soluble in water. When you’re done printing your PLA project with PVA supports, just throw the whole thing into water and wait for about 24 hours. This method provides clean, safe, and effortless support removal.

CONS

Poor heat stability

Compared to other 3D printing filaments, PLA has a relatively low melting temperature. Accordingly, it also has a low glass transition temperature of 60 to 65 °C. This limits the potential applications of a 3D printed project made with PLA. Even rubbing a piece of PLA with sandpaper too vigorously will generate enough heat for the material to deform.

Low strength

If you need something 3d printed with good tensile strength, impact strength, or flexural yield, then PLA would be a poor choice of filament. Standard PLA compares poorly in terms of mechanical properties when put side-by-side with high-performance filaments like PETG, Nylon, and Polycarbonate. However, there are now high-strength versions of PLA that can put up a better fight.

Not suitable for outdoor use

Being a biodegradable material, the properties of PLA can be heavily affected by outdoor conditions. Factors that accelerate the degradation of PLA include direct sunlight, heat, and moisture. If you need a 3D printed project that can be used outdoors, then there are more than half a dozen other filaments that would be more sensible choices.

PETG

The basics

PETG is a glycol-enhanced version of Polyethylene Terephthalate (PET), which is one of the most widely used plastics today. The addition of glycol to standard results in a polymer that is more durable and more easily workable than standard PET. The glycol enhancement also eliminates the tendency of standard PET to become brittle and hazy when exposed to extreme heat.

PETG has often been described as the filament that combines the best parts of PLA and ABS and none of their negative traits. It prints at high temperatures but is not prone to warping, does not produce unpleasant fumes, and results in a print with superior mechanical properties and heat stability.

This unique combination of properties has helped PETG become more popular in the last couple of years. Along with this has been a trend of PETG filament becoming cheaper and approaching the price point of PLA. Still, PETG still ranks below PLA and ABS in terms of how much they are used in 3D printing.

Pros and cons

PROS

Better mechanical strength

Specific values may vary from one filament brand to another, but PETG is generally much stronger than PLA and might still hold the advantage over ABS. For reference, a standard PLA filament has a tensile strength of about 32 MPa while PETG is at around 50 MPa.

PETG can also withstand more elongation before breaking. Comparing the material’s elongation at break, PLA stands at only about 4% while PETG can strength up to an impressive 21% before breaking.

Better thermal stability

PETG has a glass transition temperature of 85 °C. This is significantly higher than PLA, making PETG a much more suitable filament for high-temperature applications. However, PETG still pales in comparison to the heat stability of ABS which has a glass transition temperature of 105 °C.

More suitable for outdoor use

PETG resists degradation by exposure to UV light and excessive moisture. When combined with its above-average heat stability, a project made of PETG should be completely fine when used outdoors. In fact, PETG is one of the most commonly used materials for outdoor signages mainly because of how long the material holds up despite the conditions.

Excellent chemical resistance

The addition of glycol functional groups in standard PET makes PETG one of the most chemically stable materials used in 3D printing. This resonant ring structure helps PETG resist reacting with many solvents, acids, bases, and oils. PETG has been shown to be so stable that it can be used for medical implants and prosthetics.

Good optical properties

PETG is considered by many to be one of the best filaments to use if you want to create a perfectly clear 3D printed object. However, getting a clear PETG print will depend on a few other factors such as infill, layer height, and degree of post-processing.

CONS

Slightly more expensive

Just to be clear, the price gap between PETG and PLA has become a lot smaller nowadays. This is likely a testament to how popular PETG has become recently. Yes, you can buy a 1-kilogram spool of PETG for around or slightly above $20. Popular brands like Hatchbox and Overture are good examples.

Still, the point stands – PETG is slightly more expensive than PLA. If you’re the type to go through multiple filament spools quickly, then the difference of $2 or $3 can quickly accumulate. However, this is not that relevant if you’re just looking to buy a single spool.

Harder to handle than PLA

Although handling PETG is a lot easier compared to ABS, it still requires a bit more finesse compared to PLA. PETG prints at higher temperatures (220 to 245 °C), making it a bit more prone to warping.

Bed adhesion can be a bit of an issue when working with PETG. Although lots of sources say that it needs no bed heating, the filament still benefits from a heated bed set at 70 to 75 °C. Printing without a cooling fan all the way also helps the material develop maximum strength, although dimensional accuracy and level of detail may suffer.

The point is that printing with PETG is a more involved process. Still, PETG is nowhere near as difficult to work with as high-temperature filaments like ABS or Nylon.

No convenient post-processing options

Being chemically resistant, smoothing by dissolution is not an option with PETG. However, it is also a very abrasion-resistant material that becomes ductile when under stress. This makes sanding PETG quite difficult, especially compared to PLA. You can consider smoothing PETG using a heat gun, but this is a method that takes a bit of skill.

Which one to use?

From our discussion, it should already be quite apparent why the use of PETG is increasingly becoming more common in the 3D printing industry. It offers better mechanical and chemical properties than PLA but is not quite as complex to use as ABS. It sits somewhere in between – the perfect middle ground between the two most popular 3D printing filaments.

Still, there’s no need to exclusively use one and completely forsake the other. Both PLA and PETG have places in your filament inventory. Here are tips on the best times to use either one:

Use PLA if…

You’re a beginner

There are several reasons why PLA is often the filament recommended for beginners. With PLA, you won’t need to worry about problems with warping, toxic fumes, or bed adhesion. In other words, it’s a good way to be introduced to the world of 3D printing without too much frustration. If you’re gearing up for your first 3D printed project, go ahead and buy that $20 spool of PLA filament in your favorite color.

You’re doing trial prints

Experimenting is a natural part of 3D printing. This is necessary whenever you do maintenance on your 3D printer, replace some parts, or recalibrate some 3D printing parameters. A lot of things can go wrong at this stage. By printing with PLA, you can feel a bit less guilty about using non-sustainable plastic to print models that will likely turn to scrap.

You don’t have a heated bed

PLA is one of the few filaments that can be used even if your 3D printer does not come with a heated bed. This is the major advantage of using a filament that is not prone to warping. Frankly, you have a very limited range of filaments to work with if you don’t have a heated bed. If you’re confident with your skills, then you should seriously consider making an upgrade.

You’re printing display items or early prototypes

For all the limitations of PLA, visual appeal is not one of them. Under the right conditions, you can make clean and highly detailed prints with PLA. With sanding and polishing, you can even come up with a 3D printed project at a professional level of quality.

This is ideal for miniatures, figurines, and other items meant solely for display. Product prototypes are also ideally made with PLA, especially development is still at the early stage. If you don’t need your 3D printed part to be functional, then PLA is a suitably affordable and practical option.

Use PETG if…

You need more durability

With better tensile and flexural strength, PETG is the superior option for heavy-duty applications. It is much more suitable than PLA for functional parts or any object that you expect to withstand repeated stress or movement. The mechanical properties of PETG are comparable to that of ABS.

You’re printing something for outdoor use

PLA is a poor choice for projects meant for outdoor use. With its resistance to UV degradation and chemical attack, PETG is more appropriate for signages and other outdoor items. Outdoor items made with PETG are known to retain their properties even when exposed to rain and sunlight for a few years.

You want to upgrade your 3D printing skills

PETG is only a step below from PLA in terms of ease of use. It does not emit fumes, either, and is not overly prone to warping as long as you don’t attempt to cool it down too quickly. We recommend printing with PETG if you think you already have a good handle on PLA. It’s a great way to introduce yourself to the world of high-temperature 3D printing and will prepare you for printing with more finicky filaments.

Final thoughts

Regardless of which one between PLA or PETG is better, it’s clear that there is room for both in the 3D printing industry. Despite the simplicity of PLA, it remains a staple in the filament stock of any 3D printing professional. It’s our old reliable – the filament we reach for when we just want to 3D print something quick and trouble-free.

However, PETG also presents a compelling case as the new favorite. It’s easy enough for beginners to use but is also a lot more robust than PLA. We can see PETG becoming a mainstay in the inventory of 3D printing professionals as well, perhaps more so than ABS in the future.