What Is the Optimum Fan Speed for 3D Printing PLA?

The general rule of thumb when printing with PLA is that you can never have too much cooling. PLA benefits in terms of both strength and visual quality when printed with a part cooling fan set at 100%. However, it is still considered good practice to leave the fan disabled for the first two layers to guarantee good bed adhesion.

Why is fan speed such a big deal when 3D printing PLA? Would it be beneficial to modify your 3D printer for more efficient cooling? Will setting cooling to max compromise the other characteristics of a PLA print?

Why cooling is so important in PLA

When heated to melting temperature, PLA takes on more fluid-like characteristics. This is a common behavior for thermoplastics. However, PLA is more prone to oozing or flowing compared to other 3D printing filaments.

Without a cooling fan, the layers of a PLA print tend to become deformed. This is problematic even for models that do not have a great degree of detail. Even flat surfaces sag down when printed in PLA without cooling.

Using the cooling fan at maximum settings promotes quick solidification of the PLA layers. This helps the layers retain their shape as they are extruded. As each layer develops rigidity, it also provides reliable reinforcement for all succeeding layers.

Cooling is even more important if you’re printing PLA parts that have overhangs or bridges. As mentioned, PLA is not the strongest or most rigid 3D printing material. Even if you follow the 45-degree rule, an overhang made of PLA can still fail if it is printed without cooling.

It massively helps that PLA rarely encounters any warping-related issues. This means that there is very little disadvantage to maximizing the cooling rate of the material. However, there are still a few consequences that you may want to avoid – as we shall see in the next section.

Can your print PLA without cooling?

Now that we know how beneficial cooling is for PLA, would there be any reason to print PLA without cooling? As with any other 3D print made via the FDM method, the layer boundaries are the weakest points of 3D printed PLA. Allowing the filaments to “melt” into each other enhances layer adhesion and enhances the part’s overall strength.

This strength advantage is one that you miss out on when you print PLA at maximum cooling. Maximum cooling may make a PLA print look good, but it definitely will not be as strong. It is still a viable strategy for applications where mechanical strength is not important.

However, you can still try to print PLA without cooling if you need your finished parts to be as strong as possible. You will want to adjust both the printing temperature and speed to the lowest recommended values for PLA. Taking it slow will help prevent the PLA layers from flowing or oozing to deformation.

Getting it to look good will be a challenge but it is still possible. Pulling this off is also a lot easier when 3D printing small parts – perhaps something in the magnitude of 6 centimeters in every dimension. This makes the part less likely to deform simply on account of the bottom layers not having to support a large weight.

Possible 3D printer modifications to enhance cooling

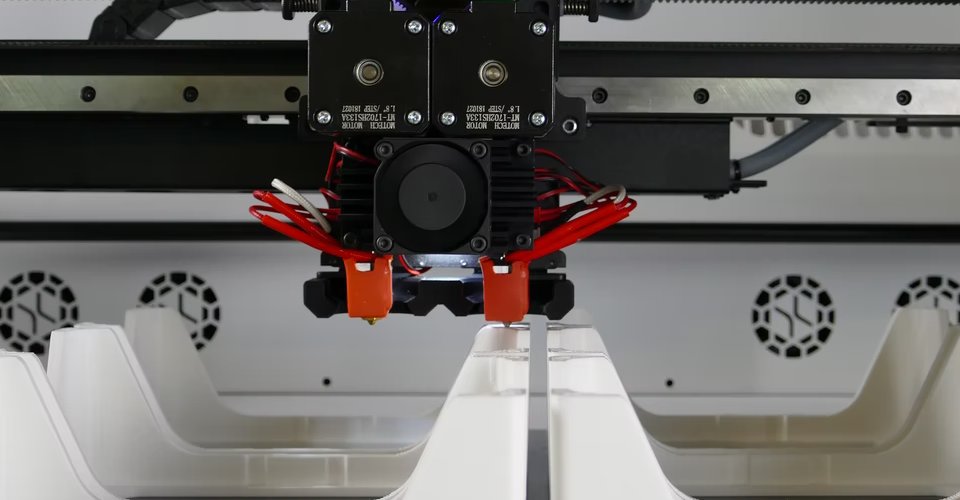

Lots of 3D printing hobbyists would say that the best fan for 3D printing PLA would be two fans. This is just a roundabout way of saying that PLA will always benefit from more cooling. This does not mean that you actually need two fans – you can modify your 3D printer instead to make cooling more effective.

The first thing you will need is a dedicated part cooling fan. This is a fan that is directed to the layers as they are extruded. If your 3D printer does not have one, it is possible to use redirect the airflow from the extruder cooling fan to the part using a fan duct modification.

There are several other ways to introduce active cooling to your 3D printer depending on which 3D printer model you are using. For instance, this fan mount and duct modification is compatible with MK7, MK8, and MK9 extruders.

One of the most sophisticated modifications we have seen for part cooling is this Petsfang duct and fan base. The duct has narrow outflow exit points that are directed almost horizontally so that they cool only the freshly extruded filament. This results in exceptionally better bridging capability, even for filament as soft as PLA.

Should you decide to modify your 3D printer to maximize cooling, keep in mind that consistency is more important than the cooling rate. You will want to make sure that all the sides of the part you are printing are being cooled equally fast. Failing to do so will likely result in some sections of the print getting heavily deformed.

Final thoughts

PLA is considered by many to be the easiest filament to work with. However, it is still not as foolproof as you may believe. Consistent and rapid cooling is needed to make sure that your PLA prints come out with a nice finish and quality.

Fortunately, the solution to this potential problem is quite simple – just cool your PLA prints as quickly as possible. If your printer has a parts cooling fan, then crank that up to 100%. You can also make modifications to your printer or extruded to make cooling even more efficient.