What is the Melting Point of PLA?

Being good at 3D printing means understanding the physical and chemical properties of the materials you are working with. One important characteristic is how the material responds to heat. An example of this is knowing the melting temperature of PLA.

PLA has a melting temperature between 160 to 180 °C, although this can vary based on the presence of additives or dyes in the filament. However, PLA can start deforming well below its melting temperature. It is just as important to know the glass transition temperature of PLA – 60 to 65 °C – where the material starts to lose rigidity.

Simply knowing the numbers isn’t enough. To gain a better appreciation of 3D printing plastics, let’s take a closer look at the mechanics of how PLA responds to elevated temperatures.

What happens when PLA melts?

Just like other materials used for FDM-based 3D printing, PLA is a thermoplastic. The unique characteristic of a thermoplastic is that it can be melted down and solidified without compromising any of its essential characteristics.

At the molecular level, the intermolecular bonds of a thermoplastic merely stretch or become more pliable when heat is applied. Even at the melting temperature, these bonds remain intact. However, the bonds become long enough to make the material very flexible or fluid-like. At this state, a thermoplastic can be manipulated via molding or extrusion.

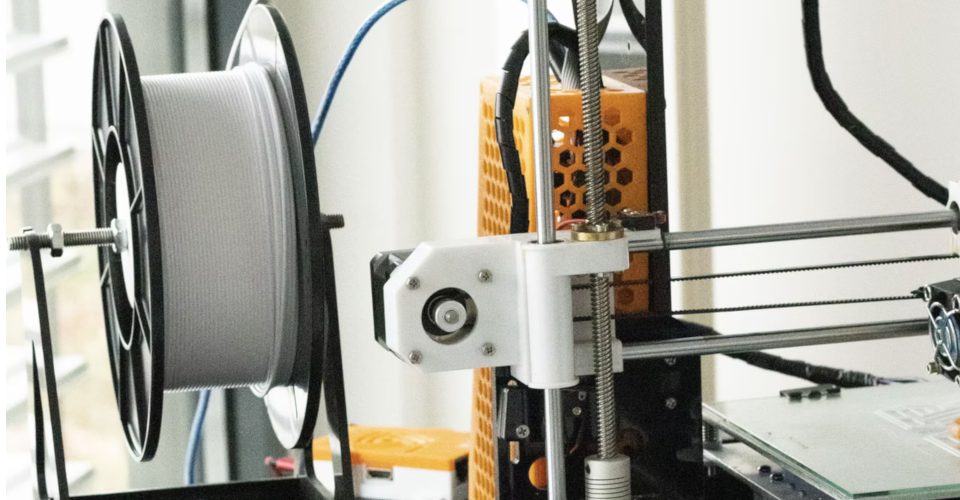

In 3D printing, the PLA filament needs to be exposed to temperatures high enough for it to melt. This happens in the “melt zone” of the hot end. This allows the extruder to push the molten PLA through a small nozzle. The PLA is then laid down on the build plate in a highly controlled and precise manner.

Why does PLA melt inside a hot car?

A common nugget of advice in 3D printing is to never leave a PLA print inside a car on a sunny day. Some would even go as far as to say that prints made of PLA are not suitable for outdoor use, especially if they are exposed to direct heat from the sun.

While there is no way for the internal temperature in a car to reach PLA’s melting temperature, PLA’s glass transition temperature is much more attainable. This is the temperature at which the material becomes less of a solid, losing its rigidity and becoming more viscous. For PLA, the glass transition temperature is within the range of 60 to 65 °C.

If you want to keep your PLA prints from deforming, make sure that they are not exposed to temperatures within the range mentioned above. This is why PLA prints are often recommended as display pieces for indoor spaces.

In the 3D printing process, the glass transition temperature of a material is important as it is often the basis for the recommended build plate temperature. Maintaining the base layer of the print near or at the glass transition temperature massively helps in bed adhesion. The flexibility of the material at this state also helps prevent warping by allowing for more even distribution of thermal stress.

Comparing PLA to other 3D printing filaments

PLA is considered a 3D printing filament that has one of the lowest thermal resistance values. In comparison, ABS has a melting temperature of 220 °C, PETG melts at around 230 °C, and HIPS at around 225 °C.

The lack of thermal resistance of PLA becomes even more glaring when glass transition temperatures are compared. While PLA starts losing rigidity at 60 °C, ABS can withstand being heated up to around 105 °C before it starts exhibiting fluid-like properties. Similarly, PETG has a glass transition temperature of 80 °C, HIPS at around 90 °C, and Polycarbonate at an impressive 140 °C.

Looking at the numbers, it is clear why PLA is the least preferred 3D printing filament for any application that involves exposure to extreme temperatures. PLA is typically not appropriate for outdoor use and will certainly deform if placed inside a dishwasher.

Annealing is a technique that can be done to enhance the thermal properties of PLA. This process involves heating PLA slightly above its glass transition temperature and allowing it to cool down very slowly. This encourages the formation of crystalline structures in PLA, thereby giving it better heat stability and mechanical strength.

Final thoughts

Despite not being known for good thermal stability, PLA remains one of the most widely used materials in filament-based 3D printing. This is mainly because of how easy the material is to work with. It massively helps that PLA is not prone to warping, does not require a heated bed, and is much more forgiving compared to other filaments.

Knowing the melting points of different 3D printing filaments is easy but understanding how the materials react to heat is a lot more important. In the case of PLA, it is this deeper understanding that has led to the discovery of annealing as a technique for bridging some of its performance gaps.