Should You Print with PETG Instead of PLA?

PLA has long been the standard default filament for casual 3D printing. It’s inexpensive, very easy to print with, and is regarded as one of the least toxic 3D printing materials. However, the inadequacies of PLA are also hard to overlook, causing many users to look for more robust materials when 3D prints are needed for heavy-duty applications.

PETG is considered by many to be the next-best alternative to PLA. This has come to a point that some people have completely replaced their PLA spools and printed almost exclusively with PETG. Is this something you should consider as well?

Why is PLA not an all-around filament?

PLA is considered the most widely used filament material in 3D printing, especially now that desktop-scale 3D printers have become very popular. PLA is quite inexpensive – you can get a 1-kilogram spool nowadays for $20 to $30. Printing with PLA also does not present any of the typical issues that can intimidate beginners to the hobby such as warping or toxic fumes.

However, most users also know that PLA is not all-around filament material. PLA is not exactly known for being strong or resilient to extreme conditions. If functional parts are being designed, hardly anyone would even consider printing with PLA.

It is exactly these drawbacks of PLA that have given way to the rising popularity of PETG. PETG is often described as the filament that offers the best of both worlds of the two most popular 3D printing filaments, PLA and ABS. It is mechanically strong, has good thermal stability, and is not highly prone to warping.

Given the comparison between the two, is it really fair to recommend not printing with PLA altogether? How do these two filaments compare in a head-to-head battle?

PETG vs PLA – which is better?

Let’s get the similarities of the two filaments out of the way before we describe how they are different. Both PETG and PLA are thermoplastics, which means they can both be melted down and solidified several times without any loss of mechanical properties.

As 3D printing filaments, they are both known to not release any noxious fumes during printing. This can be particularly problematic when printing with ABS. However, this does not mean that ventilation is no longer necessary when printing with PLA or PETG – ventilation is always a good idea, regardless of which filament you’re using.

Ease of printing

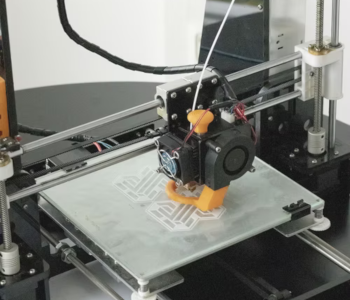

PLA has long been known as the filament that is most beginner-friendly. It prints at low temperatures, does not need a heated bed or enclosure, and does not warp even without any bed adhesion aid.

Although PETG is far from being the most difficult filament to deal with, it still requires a bit more preparation and skill than PLA. PETG prints at higher temperatures, perhaps even beyond the scope of a PTFE-lined hot end. PETG also benefits greatly from the use of a heated bed and an enclosure.

Since it prints at higher temperatures, PETG is also more prone to stringing. This may require playing around a bit with the retraction settings in your slicer. This isn’t particularly difficult but is one more thing you will have to learn if you’re a beginner.

Printing performance

One other thing that has made PLA popular is the fact that it prints really well. Even at low temperatures, PLA exhibits excellent layer and bed adhesion and retains a good level of detail. PLA is also more forgiving in terms of sub-optimal slicer settings and imperfect printing environments. There could be a draft blowing through your 3D printer and PLA will still turn out fine.

As mentioned, PETG is more prone to stringing. When printing with PETG, you need to be more particular about calibrating your extruder, setting the right hot end and bed temperature, and tuning your retraction settings. The quality of PETG prints can vary greatly depending on how you set up your slicer.

Warping

Warping is just one of those things you will eventually have to deal with once you decide to get a 3D printer. There is one worthy exception to this – when you print with PLA. It’s likely because of the low printing temperature and low thermal shrinkage of PLA, but you hardly have to worry about warping with this filament. A heated bed isn’t necessary for PLA, but having one does help.

To be fair, warping is a less pronounced problem with PETG especially compared to other filaments that print at the same temperature range. You will still need a heated bed with PETG, and an enclosure could still help, but just the basic precautions will be more than enough. Still, there is still a very slight chance of warping becoming a problem with PETG if you’re not prudent.

Heat stability

The ideal printing temperature of PLA is between 200 C and 230 C. The printing temperature of PETG is slightly higher, from 220 C to 250 C. This can have a few ramifications in terms of preparing your 3D printer, such as having to use a heated bed and an all-metal hot end. However, the biggest difference that the printing temperature makes is the thermal stability of the finished product.

It is often said that PLA prints should not be kept inside a car on a hot day. With a glass temperature between 50 to 80 C, PLA prints can certainly heat up easily to the point that they start to deform.

The glass temperature of PETG is slightly higher at around 85 C. At this temperature, PETG can be considered suitable for printing items for outdoor use or even for functional parts. In the category of thermal stability, PETG is clearly superior.

Mechanical strength

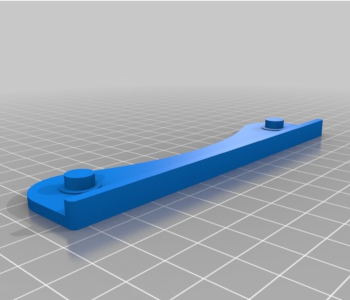

From a basic perspective, PLA prints tend to turn out stiffer while PETG is a little more flexible. If you need to print something with good impact resistance, then PETG is a lot more appropriate, although there are other 3D printing filaments that perform even better in this aspect.

This observation can also be supported by actual trials. Based on a tensile strength test, PLA has a tensile strength of 7080 psi while PETG’s is 7690 psi. This is a fairly large difference and is enough to justify recommending PETG for more functional parts. If you’re printing replacement hinges or brackets, then PETG is one of the better options.

Outdoor use

There are two factors that work against PLA when it comes to resilience in outdoor conditions. The first is that PLA is not UV-resistant and tends to get brittle after extended exposure to direct sunlight. The second is that PLA takes up moisture more readily than PETG. When left in environments with high moisture, PLA tends to deteriorate faster.

PETG performs a bit better in terms of UV resistance and moisture resistance. It is a good material for 3D printing parts for outdoor use, but it’s also not the best. Materials like Nylon or ASA will last much longer outdoors compared to PETG.

Food safety

PLA is derived from plant matter and breaks down into components that are generally safe for humans, animals, and the environment. For this reason, PLA is often the material that is recommended for food-safe prints.

PETG is no slouch in this department, either. After all, almost all water bottles used today are made from PET, the base polymer from which PETG is derived.

In both filaments, there is an important disclaimer that needs to be made. Both PLA and PETG in their base forms can be considered food-safe. However, they can have additives such as dyes and plasticizers that are not safe for food contact. If you want to print something for food contact, then you have to make sure that you’re printing with filament that has been approved by the FDA as food-safe. This rule applies to PLA, PETG, and any other 3D printing material.

Sustainability

PLA has long been known as the most sustainable material for 3D printing. This mainly comes from the fact that PLA is derived from plant matter instead of petroleum products. As one of the most common bioplastics globally, PLA has earned a reputation as one of the most viable sustainable plastic alternatives.

PETG has no such advantages. It is a traditional plastic derived from petroleum sources and is considered non-sustainable.

PLA can be broken down into constituent substances that are considered safe for the environment. This has given the impression that PLA is biodegradable. While that is technically true, breaking down PLA parts will take more than just burying them in your backyard. If you truly want them to be broken down, your best course of action would be to send them to a composting facility that will adequately handle them.

Cost

The low cost of PLA filament is one of the primary reasons for its sustained popularity. Most PLA filaments cost around $20 for 1-kilogram spools. Some brands can go even lower – some of the cheapest we’ve seen are at around $14.

PETG is only slightly more expensive and is still quite affordable. Most brands have PETG filaments that cost anywhere between $20 to $25. Sub-$20 filaments are rarer in PETG, perhaps because the material itself has a higher premium. The price difference is minimal unless you 3D print at very high volumes.

In summary, PETG fares better than PLA in terms of mechanical strength, suitability for outdoor use, and thermal stability. On the other hand, PLA is still considered better in terms of ease of use, printing performance, and sustainability. Either PLA or PETG can be used for food-contact applications but you will need to check on the FDA compliance of the specific filament you are printing with.

Should you phase out your PLA spools?

Now that we’ve made arguments for both PLA and PETG, let’s go back to the original question – should you be printing with PETG instead of PLA?

The advantages of PETG are clear. It is stronger and can withstand higher temperatures than PLA, but is still fairly easy to work with. It is certainly not as intimidating as other high-temperature filaments like ABS, Nylon, or Polycarbonate. It is also an inexpensive filament, although still not as cheap as PLA.

However, you still cannot discount the advantages of PLA. It is still the easiest filament to work with. If your 3D printer does not have a heated bed, then you will still want to stock up on different PLA spools. It is also a very forgiving filament, making it the perfect material for trial prints and prototypes.

Most importantly, the sustainable nature of PLA makes it the lesser evil when it comes to misprinting and 3D printing scraps. This does not mean that you can just waste PLA without consequences – disposing of PLA still requires non-sustainable resources. However, you can be a little less guilty of using up plastic unnecessarily.

Here’s the short answer – it makes no sense to ditch PLA completely, even if PETG delivers superior results. It’s not like you need to, of course. Having a diverse choice of materials to print with is one of the best things about 3D printing.

If you’re not printing functional parts, then it’s still much better to stick with good old PLA. Having some PETG on the side is also good for when you need to print parts for more heavy-duty use. As mentioned, PLA is also a good material for printing prototypes if you’re still developing a new part or product.

Final thoughts

PLA has reigned for a long time as the most widely used filament in 3D printing. Whenever this topic comes up, some users will exclaim that this should no longer be the cause now that we have PETG.

The good thing is that you don’t really need to choose when you can have both. There is actually a very compelling case for having both, as each filament brings something unique to the table. PLA and PETG will likely remain two of the most popular filaments in 3D printing, and deservedly so.