Exciting Innovations in Plastic Recycling Technology

Plastics are everywhere – we use them as furniture, as food containers, as fabric material for clothes, and as bags for takeaway food. Unfortunately, they also tend to end up in landfills and oceans. The plastic waste problem continues to be challenging despite any efforts to limit use straws, single-use plastic bags, or bottles water.

Recycling plastics is one of the solutions that is considered more sustainable over the long term. Research on the development of better plastic recycling has been quite active in the last few years. To give us a bit of hope that this battle is not hopeless, let’s take a look at some of the most exciting developments in this field.

Plastic-ingesting bacteria

A crucial step of recycling or disposing any plastic is breaking it down into smaller particles. The goal is to reduce plastics to their constituent compounds, therefore making them less harmless and more useful for repeat applications. However, this is easier said than done. The polymer compounds of plastics are very stable, which is one of the primary reasons for why plastics are used so widely.

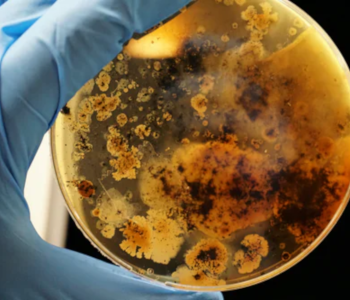

Scientists around the world have spent the last couple of years optimizing a process that will allow a specific bacteria strain to break down plastics. The bacteria – Ideonella sakaiensis – was first discovered by Japanese scientists back in 2016. The capability of the bacteria was first exhibited by breaking down PET into its constituents, ethylene glycol and dimethylterephtalate (DMT). The fact that it works on one the most widely used plastics was enough to show that there was great potential in the idea.

Today, there are multiple efforts in this front. In 2016, scientists in Pakistan discovered a fungus that can also break down plastic. A biology student in Oregon found a species of plastic-eating bacteria after collecting samples from a nearby oil site. Scientists from South Korea, China, Germany, and France have also reported similar breakthroughs.

One flaw of the original experiment on Ideonella sakaiensis was that the breakdown process was still too slow. For this method to be practical, it has to be accelerated. This is the focus of the work being done by a group of Danish researchers. Instead of studying the bacteria, the researchers focused on the two enzymes that the bacteria used to break down plastics. Through protein engineering, these enzymes can be made to work faster.

A French company called Carbios is now targeting the establishment of an industrial demonstration plant for the enzymatic breakdown of plastics by the second half of 2021. The enzyme they are using specifically depolymerizes PET. If the facility works according to expectations, it can produce 100% recycled PET that is of the same quality as virgin PET. This is only the first step in the group’s target of constructing a full-sized industrial unit for enzyme-based PET recycling.

Using recycled plastic to build roads

Another way to deal with excess plastic waste is to repurpose them for critical applications. Many countries around the world already have roads that incorporate plastic waste into asphalt and concrete. Not only are these roads low-cost and sustainable, but they also benefit from the all-weather durability of plastics.

A Scottish company called MacRebur is one of the most prominent names in this innovative field. Using a material called MR6, the company claims that using recycled plastic can reduce the use of bitumen in roads by up to 10%. More importantly, roads and tarmac made with MR6 are up to 60% stronger and have 10% longer lifespans.

India has been leading the way in terms of the degree of usage of roads with recycled plastic. As of 2021, more than 60,000 miles of roads built in India have used this technology. Other countries have more recently started adopting it as well, notably Mexico, Netherlands, Vietnam, Philippines, and the US.

A huge selling factor of this technology is that it’s very simple. Companies like MacRebur can sell the recycled plastic material in the form of pellets or grains. These are then combined with sand and crushed stone and heated to 170 C to form an aggregate material. Heated bitumen is combined with the aggregate. This mixture can then be readily used for road construction.

Despite using recycled materials, several studies have shown that these roads actually perform better than traditional roads. Having a proportion of plastic material makes the roads more flexible, making them loss prone to cracks and potholes. The use of plastics also reduces carbon emissions in the manufacturing process of asphalt.

The great thing about roads as an alternative avenue for plastic waste is that there are lots of them. A large volume of plastic waste can go towards this application, especially as more countries adopt the technology. Some groups have expressed concern that these roads can cause shedding of microplastics into the ocean. However, this possibility is still being studied.

AI-aided plastic sorting

One major challenge faced by plastic recycling facilities is sorting. Before any treatment can be done, plastic waste must be sorted according to plastic type, size, weight, color, or the presence of contaminants. This is typically done by humans, severely limiting the capacity of a facility to accept recyclable materials. Retention of personal has also become challenging – after all, most people do not look at sorting trash as a long-term job.

Plastics that are not outright fit for recycling can be considered poor-quality feedstocks and rejected by plastic recycling facilities. These then end up in a landfill or incinerator. This was the case when China started rejecting recyclable materials from the US back in 2018 because of contamination issues.

To reduce the reliance on manual work, researchers have been developing AI-powered robots that can do automatic waste sorting. These are equipped with cameras that can identify specific items which are then sorted using robotic arms. Items are identified according to color, size, and shape. According to reports, these robots can work about twice as fast as humans with comparable accuracy.

A research being done in the Distributed Robotics Lab in MIT aims to add tactile sensors to this waste-sorting robots. Another development by AMP Robotics seeks to augment these robots with machine learning, allowing them to be “smarter” as they sort through more items. These technologies can help make waste-sorting robots more efficient, especially if they need to go through a more diverse feedstock.

Making Ecobricks from spent plastic bottles

The Ecobrick movement is one of the more well-known initiatives to reuse plastic waste. An ecobrick is simply a plastic bottle which has been compactly packed with other waste plastic items. The goal is to use these ecobricks as building blocks for walls or furniture. They are often reinforced with cement or silicone.

In 2013, the Global Ecobrick Alliance (GEA) was formed by the leaders of ecobrick movements from different countries. This move helped in global dissemination and in setting the standards for building ecobricks around the world. Today, the GEA has presence in the Philippines, Indonesia, South Africa, the US, and UK. They also have certified trainers who can teach people how to properly make ecobricks.

The principle of ecobricks is sequestration. Instead of having plastic end up in landfills, incinerators, or the ocean, they can be kept away inside of constructed structures. Ecobricks prevent the exposure of plastics to the sun, heat, or oxygen, which can break down the plastics to harmful carbon byproducts.

Building structures out of ecobricks makes use of the cradle-to-cradle concept. This means that the ecobricks are meant to be reused when the structure is taken down eventually. Using silicone or Earth-based building materials means that the ecobricks can be recovered without damage.

Today, ecobricks are being used as building materials in the Philippines, India, Serbia, and in the USA. In Argentina, a family built their home using almost exclusively ecobricks – around a thousand bottles in total. The ecobrick movement has been around for a decade but is still very much in its infancy.

Smart polymer materials

An alternative approach to recycling plastics is to design the polymers themselves to be easily recyclable. This is one of the goals for the development of “smart polymers.” These polymers are designed to react to an external stimulus, allowing them to be more controlled. This makes it possible for the recycling properties of the plastic to be intrinsic.

As an example, a polymer can be designed to have a large change in properties upon exposure to light or a specific temperature range. For recycling, such a feature can be triggered when the object has reached the end of its useful life. This can aid in the removal of contaminants of plastic items or the complete breakdown of plastics into their constituent chemicals.

An EU-funded consortium called DECOAT aims to apply this technology on plastic-based coatings, adhesives, and other finishing agents. Devan, a member of this consortium, has been tasked with the specific goal of developing an additive that can separated the coating material upon the application of a specific trigger. The additive can either be contained in microcapsules or a compound mixed with the coating that can be activated by a stimulus like the emission of microwaves. This should make the recycling of these coated materials easier and make them less likely to end up in landfills.

Final thoughts

By now, it hardly needs to be said that the plastic waste problem is one that we need to prioritize. Lots of us have already made conscious efforts to reduce plastic use, whether by carrying around a reusable water bottle or refusing single-use takeaway plastic bags. These efforts still aren’t enough.

Recycling is one way to reduce plastic waste, but it has become painfully apparent that it is still too limited. The innovations we have discussed are some of the ways to make recycling more effective.