Best Polycarbonate Filament, How to Use Them, and Where to Buy

Anyone experienced in 3D printing will know that however popular ABS and PLA are, both of them have a lot to be desired in durability. They are tough enough for the most basic applications, but they just are not meant to withstand strong impacts or any sustained force. Fortunately, polycarbonate filaments offer a work-around to this problem. If making super durable 3D prints sounds like something you would be interested in, then read on for the best tips in using polycarbonate filaments and the best brands in the market.

What are polycarbonate filaments?

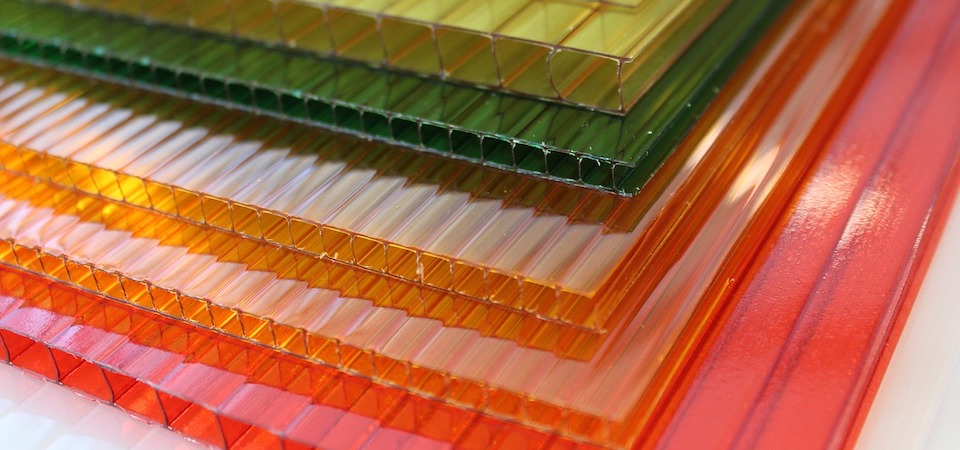

Polycarbonate is often touted as the strongest material available for consumer 3D printing. It exhibits superior impact resistance and tensile strength, on top of being lightweight and transparent. With its impressive physical properties, polycarbonate has been used in applications that demand high levels of durability such as riot gear, scuba masks, bullet proof glass, electronic display screens, and construction materials.

Polycarbonates are so called because they are composed of polymers containing carbonate groups. Aside from being physically durable, polycarbonate also exhibits temperature resistance and optical properties. The repeating functional groups in the polycarbonate chain are highly polar, which gives the material its unusual strength. Despite its toughness, polycarbonate is still a thermoplastic which can be shaped and reformed once treated with high temperatures.

What are the benefits of using polycarbonate filaments?

As already mentioned, polycarbonate is probably the most durable material you can work with to make 3D prints. It can stand up to most demanding applications, is able to bend without cracking or breaking, and has very good temperature resistance. Compared to glass, polycarbonate has a much higher impact strength while having less than half the density.

In terms of tensile strength, polycarbonate is comparable to polymethyl methacrylate (PMMA). However, it can flex without breaking better than any other plastic, including PMMA, PLA, and ABS.

Aside from being very durable, polycarbonate also has excellent optical properties. Its transparency is comparable to glass, and it transmits visible light better than most other plastics such as PETG. Prints made from polycarbonate are not only strong, but you can make them look really good.

Although its temperature resistance can be considered an advantage in the final print, it can also be considered a drawback during the printing process. As should be apparent shortly, 3D printing with polycarbonate filaments can be quite demanding in terms of printing temperature.

How do you use polycarbonate filaments?

One of the first things you need to keep in mind when using polycarbonate filaments is that they are highly hygroscopic. This means that these filaments will readily absorb moisture when exposed to the atmosphere. Polycarbonate filaments are shipped in airtight bags with desiccant packs to manage their moisture absorption, and it is advised to keep them in similar conditions during storage. Printing with moisture-laden filaments is bad news, as those little air bubbles will vaporize and pop during printing. The result will be a messy print filled with holes and gaps.

As already mentioned, polycarbonate has a high temperature resistance. For this reason, the printing temperature of polycarbonate filaments is also similarly high, with a recommended value of 300 °C. Obviously, not all desktop 3D printers are designed for this kind of temperature.

Some users have reported some success in printing polycarbonate using a print temperature of only 265 °C. The only caveat is that you will have to print at a lower speed of 30 mm/s. For reference, printing at 300 °C will allow you to print at a speed of 60mm/s.

A heated printing bed is non-negotiable when printing with polycarbonate. In fact, you are going to need to set the bed at very high temperatures of 90 to 120 °C to avoid warping. In this case, a higher temperature will better avoid delaminating issues.

Bed adhesion for polycarbonate filaments is a little more complicated than usual, with most users recommending a combination of Kapton tape and a layer of ABS glue. You may also apply a layer of glue stick on a heated bed, taking note that heating up glue to the temperatures needed by polycarbonate may release toxic fumes. In the interest of safety, make sure to print in a well-ventilated area when using this setup.

Finally, make sure that you are not using a cooling fan when printing with polycarbonate filaments. Polycarbonate needs to cool down slowly to complete the curing process, thereby providing durability to the final print. For best results, we recommend using an enclosure when printing using polycarbonate filaments. You may buy a pre-manufactured enclosure for this purpose, or make your own.

Are there any drawbacks in using polycarbonate filaments?

Polycarbonate may be a very durable material when it comes to impacts and flexural stress, but it is also quite prone to scratches. This is quite problematic, as scratches can severely diminish the almost glass-like transparency of polycarbonate. Fortunately, this is a problem that has already been solved by other people who have developed a scratch-resistant coating for polycarbonate. Most safety glasses you can buy nowadays are made of polycarbonate with a scratch-resistant treatment.

To be honest, the major drawback of polycarbonate filaments is the difficulty in working with them. They require a hot end that is capable of reaching very high temperatures of up to 300 °C. Not only is a temperature like this difficult to reach, but it is also difficult to maintain. The sensitivity of polycarbonate when it comes to printing temperature may lead to problems such as under-extrusion or stringing should your temperature drop unexpectedly.

Having a high temperature resistance also means that polycarbonate prints have a very high tendency to warp. This is another reason why maintaining a high printing temperature is very critical when printing with polycarbonate filaments. Having an enclosure around the printer will greatly aid in solving this problem by slowing down the rate of cooling of the final print.

Polycarbonate is also a very finicky material when it comes to adhesion. Polycarbonate just does not want to stick to anything, which means you will have to apply a liberal amount of adhesive to your printing bed to prevent warping of the polycarbonate print.

What are the best brands of polycarbonate filaments in the market today?

There are surprisingly a good number of brands offering polycarbonate filaments in the market. Below are some of our top picks:

- The GizmoDorks Polycarbonate Filament is available not only in natural transparent, but also in black and blue. This product promises to deliver all the advantages of polycarbonate: durability, flexibility, and good transparency. GizmoDorks is a reliable and quite well-known brand, so you can depend on them to deliver on their promises. The polycarbonate filament by GizmoDorks is available in both 1.75 mm or 3 mm diameter and can be purchased in either a 200 g sampler spool or the full-sized 1 kg spool.

- The ePC filament from eSun is also available in natural transparent with a black alternative. It has received a couple of good reviews, although a few users have reported issues with the reeling of the filament on the spool. Still, there are no complaints in the quality of the ePC filament and it seems to deliver on the durability expected of a polycarbonate filament. The ePC filament from eSun is available in both 1.75 mm or 3 mm diameter and are sold in 1 kg spools.

- The PC-Max filament from Polymaker is another excellently reviewed polycarbonate filament due to its top-notch strength and ease of use. This filament is available in either True White or True Black. It can be purchased at either a tester spool of 750 g, or a huge 3 kg spool.

The Roundup

| Material | Polycarbonate filament |

| Properties | – Very strong – High impact resistance and tensile strength – High temperature resistance – Good optical properties |

| Applications | – Safety equipment – Construction materials – Bullet proof glass – Scuba masks – Electronic display screens |

| Recommended printing temperature | 265 to 300 °C |

| Recommended bed temperature | 90 to 120 °C |

| Printing speed | 30 mm/s to 60 mm/s; lower printing speeds are recommended for lower printing temperature |

| Bed adhesion | Kapton tape with ABS glue |

| Cooling | No cooling fan; enclosure is recommended |

In terms of pure strength, there is nothing quite like polycarbonate filaments in the 3D printing world. It is more durable than glass while maintaining the flexibility expected from polymer materials. On top of all of these, polycarbonate prints look excellent due to its transparency.

The main hurdle in the popular use of polycarbonate is the difficulty involved in printing with it. Being a temperature resistant material, it requires a very high printing temperature which also makes it highly prone to warping. There are a lot of measures that need to be taken to print well with polycarbonate, as we have already outlined above.

If printing with polycarbonate filaments is something you want to take for a spin, we recommend getting one of the brands we have listed above. It may be quite costly to buy from a reputable brand but printing with polycarbonate is difficult enough without doing it with a cheap filament.

Here is our suggestion: get a good quality polycarbonate filament, set your printing temperature to as high as your printer can give, and print slow. In this case, slow and steady wins the race. Once you have become a little more comfortable with the filament, you can start playing around with the settings to get good quality prints faster. There is a good level of learning curve that you need to overcome when printing with polycarbonate, but overcoming it will open the possibilities to making super durable 3D prints.

Polymaker PC-Max (now PolyMax PC) is not pure PC, and has lower required hotend and bed temperatures but also lower working temperatures.