The Pros and Cons of Every 3D Printing Filament Material

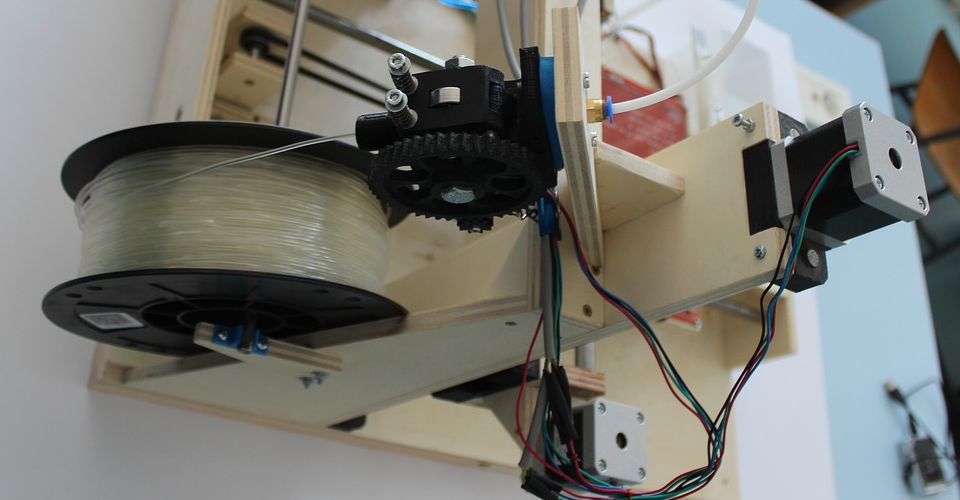

Variety is rarely perceived as a negative thing. In the field of 3D printing, variety is one of the distinguishing characteristics of FDM technology – currently the most popular of the 3D printing techniques. Aside from the technology of FDM printing making it suitable for casual and desktop-scale use, FDM also offers the widest selection of different 3D printing materials, all delivered in convenient filament form.

However, this huge variety can also prove to be overwhelming when you simply can’t afford to buy them all. To help you decide, we’ve come up with a list of pros and cons of just about every single one of the common materials used in FDM-based 3D printing.

1. PLA

The most sensible way to start this list is with one of the most widely used filaments used in FDM printing – Polylactic acid, or PLA. This is known as an extremely beginner-friendly filament because it’s easy to handle, does not require sophisticated equipment, is very cheap. If you’re trying out 3D printing for the first time, then we strongly recommend making your first print with PLA.

PROS:

Biodegradable and made from sustainable sources

By far, PLA is the most environmentally friendly choice of 3D printing filament you could use. PLA is a 100% sustainable material, as it is made from plant-based sources. It is also biodegradable and breaks down to lactic acid components, a biologically and environmentally safe compound. As a demonstration of its biological compatibility, PLA is often used as material for medical implants and skin-absorbable stitches.

Inexpensive

Being one of the most commonly available 3D printing filaments, PLA has also become one of the cheapest. If you’re on a budget, then you can probably find a 1-kilogram spool of PLA filament that costs less than $10. Just keep in mind that you will always get what you pay for – you can’t expect premium quality if you’re too stingy.

Does not produce fumes while printing

Good ventilation is a must in 3D printing as a safety measure. After all, you’re heating plastics to their melting temperature, so there’s always a good chance that some of their components get volatilized and contaminate the air that you breathe.

One of the best things about PLA is that it doesn’t release noxious fumes while printing, probably because it’s not a petroleum-based plastic. Just to be clear, though, inhaling fumes from plastic of any kind still isn’t good for your health. While the pleasant smell of PLA as it prints should afford you a bit of comfort, that’s no excuse to not wear breathing protection and to print in a place with poor ventilation.

Does not warp

PLA prints at relatively low temperatures. More than the savings on power and the reliance on basic 3D printer components, this also means that PLA has a very low tendency to warp. This is one of the reasons why PLA is such an easy material to work with. If you have no experience with 3D printing, then dealing with warping issues likely isn’t something you’re looking forward to. Even experienced 3D printing professionals will turn to PLA when they just want to print something simple without having to worry about warping.

CONS:

Poor mechanical characteristics

PLA is not known for its strength or thermal stability. If you need parts that are meant for functional testing or that need to withstand repeated use, then just about any other material would be better than PLA. The low printing temperature of PLA also means that finished PLA prints tend to deform easily. You can leave an object made with PLA inside a car on a hot day and come back to find nothing but a gooey mess.

Naturally disintegrates over time

A natural consequence of PLA being biodegradable is the fact that it has poor longevity. PLA prints are not made for long-term use as they naturally degrade to their constituent components over time, gradually losing mechanical strength as a result. If you’re working on a project that needs to be displayed outdoors, then PLA would probably be your worst material option.

2. ABS

Acetonitrile Butadiene Styrene (ABS) stands shoulder-to-shoulder with PLA as the two most widely used materials for FDM-based 3D printing. ABS is well-known for being a strong and inexpensive filament material. Unfortunately, it’s almost equally popular as a difficult material to work with.

PROS

Superior toughness, impact resistance, and chemical stability

If you need to create projects that need to have good wear resistance and are meant for functional use, then ABS is one of the more cost-efficient options. It also has remarkable chemical resistance against UV radiation, acids, oils, moisture, and common household chemicals. This resistance of ABS from most means of damage has made it one of the most widely used engineering plastics across several industries.

Good thermal stability

The thermal stability of ABS has to be emphasized, as this is one of its distinguishing characteristics. ABS prints at high temperatures, which means that it also takes a lot of heat to deform a finished ABS print. This greatly expands the possible applications of projects made with ABS, although we advise against letting ABS come in contact with hot food or drinks.

Can be finished via an acetone vapor bath

ABS is soluble in acetone, a solvent that fairly easy to find. Acetone also readily evaporates at room temperature. This allows for a unique method of finishing ABS prints to give them a smooth surface. This technique, called an acetone vapor bath, involves placing the finished ABS print inside an enclosed chamber with a small amount of acetone. The acetone vaporizes inside the chamber, effectively dissolving any imperfections on the surface of the ABS print.

Finishing via acetone vapor bath is one of the easiest ways to get a smooth finish out of a completed 3D printing project. Although it doesn’t take any effort or skill, it produces pretty consistent results.

Inexpensive

Like PLA, ABS is so commonly used and easily available. Similarly, the price range for ABS is similar at around $10 for a 1-kilogram spool. There are both cheaper and more expensive options, of course, but don’t forget that you always get what you pay for.

CONS

Highly prone to warping

Here’s the major thing you need to know about ABS before you try it out – it’s incredibly prone to warping. Not only does the high temperature of ABS mean that it goes through rapid cooling as soon as it exits the nozzle, but ABS also tends to generate a lot of thermal stress as it cools. This means that ABS tends to deform because of thermal stress, often manifested in the base layer of the print “lifting off” the print bed at the corners.

The warping behavior of ABS means that you’ll need to take on a lot of measures to get an ABS print to look perfect. Among other measures, you’ll have to print on a heated bed, treat the bed with proper adhesives, and enclose the printing chamber to maintain an elevated temperature. It’s a lot to deal with, especially for someone without experience.

Gives off toxic fumes

ABS releases styrene when it is heated, which is a known carcinogen. Not only are fumes from ABS toxic, but they can also be very irritating and noxious. This makes good ventilation and proper breathing protection particularly important when printing with ABS. An enclosed 3D printer that blows the fumes through a HEPA filter would certainly help lower the concentration of toxic compounds in the air, but this will only delay its accumulation in a room with no ventilation. It’s still better to simply crack open a window and don’t linger in the same room unnecessarily.

3. PETG

Polyethylene Terephthalate (PET) is pretty familiar to everyone. PETG is simply a glycol-enhanced version of standard PET, which means it’s a little more chemically stable, heat-stable, more flexible, and more impact-resistant. In the field of 3D printing, PETG is known as a material that is remarkably suitable for projects made for outdoor use.

PROS

Chemically stable

The addition of glycol groups to standard PET gives it an incredible amount of chemical resistance. Glycol has what is known as a resonant ring structure, which makes it highly stable against reactions with many acids, bases, and solvents. Products made with PETG are undeniably durable and long-lasting, making it a material of choice for many prosthetic devices. Outdoor use is also one of the common uses of PETG, as it also resists degradation by UV radiation.

Good flexibility and impact resistance

Compared to both ABS and PLA (and standard PET), the impact resistance of PETG is superior. Its flexible nature means that it can withstand repeated or sustained applications of force. PETG is prime material for functional prototypes or replacement parts for actual functional use.

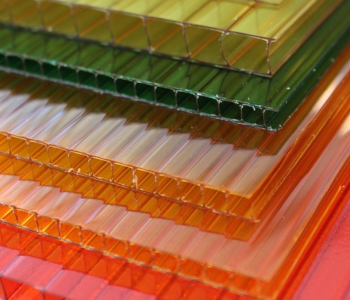

Good optical properties

PETG is naturally clear plastic and is considered by many to be one of the best filaments if you want to create completely clear 3D printed objects. To get a 3D printed project to get to that point, however, a good amount of post-processing will be needed.

CONS

Tough to finish

As we’ve already mentioned, PETG is an exceptionally tough and chemically stable material. While these are desired characteristics for the end-product, it also makes 3D printed objects made from PETG difficult to finish. Its naturally ductile behavior when under stress makes it resistant to mechanical finishing methods, while its chemical stability means that there aren’t any easily available solvents that can dissolve it.

The choices for finishing PETG prints involves either heat treatment, which requires a bit of skill, or old-fashioned sanding and polishing. Either way, it’s a lot tougher to finish PETG compared to other filaments like PLA.

Expensive

PETG isn’t monumentally expensive, but it is a little pricier compared to more common filaments like PLA and ABS. A 1-kilogram spool of PETG will likely set you back $25 to $35. It’s not a huge amount but might be enough to dissuade you from experimenting with it just for fun.

4. Nylon

Nylon is another material that should be quite familiar to everybody. Nylon is a generic term that refers to synthetic polyamide and can be found just about everywhere – from clothes to toothbrushes, military equipment, and parachutes. Considered as one of the most valuable synthetic materials ever created, nylon is very strong, resistant to abrasion, chemically stable, and has a low coefficient of friction.

PROS

Very strong, yet flexible

It only takes a small glimpse of some of the applications of nylon to understand how strong it is. Nylon is used as reinforcement for car tires, parachutes, heavy-duty ropes, tents, and other military supplies. It also has an exceptional strength to flexibility ratio, which means that it retains good tensile strength despite retaining a good deal of flexibility. This makes nylon quite easy to work with across several industries.

Heat-stable

Nylon is one of the most heat-stable filaments used in FDM printing. If you need to 3D print a part that is meant to be exposed to high temperatures, then there are few materials more suited for the job than nylon.

CONS

Prints at very high temperature

Nylon prints at a very high temperature – even higher than ABS. Aside from the problems related to printing at high temperatures (as we shall see later), this also makes nylon inaccessible as a filament material to many desktop-scale 3D printers. The temperature that nylon needs for the heating element and the heated bed are simply too high for 3D printers that aren’t meant for professional use.

Prone to warping

Just like ABS and other high-temperature filaments, nylon has a high tendency to warp. Again, you’ll need to take the usual measures to avoid warping when printing with nylon. This includes using a heated bed with the appropriate adhesive and a print chamber enclosure. For more extreme circumstances, you may also consider printing with a brim or raft.

Degrades under UV radiation

Despite the strength of nylon, it is very vulnerable to degradation by UV radiation in its raw form. Fortunately, there are nylon filament products that have been reinforced with a UV stabilizer compound. It’s best to ask the manufacturer if you’re unsure about the UV compatibility of any specific nylon filament.

5. TPU

ThermoPlastic Polyurethane (TPU) is a more recent version of ThermoPlastic Elastomer (TPE), just so we don’t get confused between the two. They are both known as flexible filament materials ideal for creating rubber-like 3D printed projects. Compared to TPE, TPU has slightly higher hardness making it easier for the extruder mechanisms of 3D printers to convey. While this is not a perfect solution to the problems typically encountered with flexible filaments, the upgrade to TPU has certainly helped significantly.

PROS

Rubber-like flexibility

The main reason for why anyone would 3D print with TPU is that it creates uniquely rubber-like products. This extreme flexibility allows a TPU object to retain its shape even after it becomes heavily deformed by the application of force. Its resistance to abrasion and ability to retain its flexibility even at low temperatures has made TPU a valuable material for automobile parts, medical devices, sports goods, and outdoor equipment.

Excellent layer-to-layer adhesion

The soft nature of TPU allows its layers to essentially fuse into each other during 3D printing. This gives TPU prints a quality of layer-to-layer adhesion that is difficult to simulate with any other filament material. Considering how heavily a TPU project can get deformed, this excellent layer-to-layer adhesion comes highly needed.

CONS

Difficult to handle

The flexibility of TPU may be its most desired characteristic, but it’s also the number one reason for why it’s a challenging filament to work with. Any incompatibility of printing speeds and temperatures can result in the filament bunching up within the extruder assembly and causing clogs. Printers with Bowden extruders are particularly problematic as they extend the filament path, thus allowing a longer segment of the filament to deform.

Poor bridging performance

When printing bridges or overhanging features, 3D printers often rely on the filament material quickly developing strength as it cools down so that the part does not collapse under its own weight. Unfortunately, TPU has no such advantage. Overhangs and bridges fare poorly when printed with TPU, often requiring the use of support structures.

Cannot be smoothed or polished

The ability of TPU to deform makes it very resistant to abrasion or wearing down via friction. This all but eliminates smoothing and polishing as a viable way of finishing a TPU print. In most cases, what you see is what you get when printing with TPU.

6. Polycarbonate

Polycarbonate (PC) is a polymer made of repeating carbonate groups, making it a highly polar compound. This makes the material exceptionally strong. In fact, many 3D printing professionals consider PC to be the strongest filament material available for consumer-grade FDM printing. As a testament to its toughness, PC is an essential ingredient in heavy-duty applications such as bulletproof glass, police riot gear, and scuba masks.

PROS

Strong, flexible, and heat-stable

In terms of overall strength, there are only a few filaments that can compete with PC. The superior tensile strength of PC keeps it from breaking or failing even upon application of any strong impact. PC also combines this strength with a good deal of flexibility and temperature resistance. If you need a 3D printed part that can stand up to repeated use or any challenging conditions, then PC is always worth consideration.

Good optical properties

Clear PC filaments are among the best choices if you need a clear 3D printed part. PC transmits light better than most other plastics, although you will still need to do a bit of smoothing and polishing to get a PC part to be completely clear.

CONS

Requires very high printing temperatures

Most PC filaments require printing temperatures as high as 300 C, making stock desktop 3D printers entirely unsuitable to handle the material. Aside from needing the hot end to reach this temperature, a 3D printer will also need to have a high-end heated bed and an extruder assembly that does not use standard PTFE for the idler component. For these reasons, PC filament is typically only printed using professional-grade 3D printers.

As you should expect by now, PC is also highly prone to warping. The usual anti-warping measures apply here – applying an adhesive, heating the bed to the appropriate temperature, and using an enclosure. PC is a notoriously difficult material to work with. If you’ve never used PC before, you’re probably going through few cycles of trial and error before you can get it right.

Prone to abrasion

PC may be strong, but its lack of flexibility makes it highly prone to abrasion. This is most problematic if your goal is to make PC prints that have glass-like transparency. As with any material, even micro-abrasions can cause internal reflections in a PC object thus making it look more translucent than clear. If you’re making clear 3D printed projects using PC, make sure to apply a scratch-resistant coating as the final step of your finishing process.

7. PVA

Polyvinyl Acetate (PVA) has a very special use case because of its unique characteristic – it is a plastic that dissolves completely in water. This may make PVA an impractical material for actual 3D prints, but it also makes it the perfect material for support structures. Naturally colorless and odorless, PVA is the go-to support material when printing with PLA and other materials that print at low temperatures.

PROS

Dissolves in water

The solubility of PVA in water is what makes it an excellent support material. As those who are experienced with 3D printing will know, support structures are a necessary evil when printing models with lots of overhangs. Not only do support structures use up a lot of additional filament, but they can also be so difficult to remove that they often risk damaging the actual part being printed.

PVA removes the difficulty of removing support structures because a finished 3D print can simply be dissolved in water for a few hours. The lack of any need for special solvents is also a huge advantage.

Good bed adhesion

With the correct print temperature settings and with proper bed adhesion, you should not have any problems getting PVA to stick to your print bed. This is highly essential in the role of PVA as a support material.

Breaks down into non-toxic compounds

When PVA dissolves in water, it simply breaks down into its component vinyl alcohol monomers. This is a non-toxic compound that isn’t harmful to the environment in small amounts and can be safely disposed of in your sink. You will want to liberally flush down your pipes after disposing of the dissolved solution to avoid any saturation of PVA.

CONS

Compatible only with low-temperature filament

PVA optimally prints at temperatures between 185 C and 200 C. This greatly limits the possible applications of PVA, as it will almost certainly fail if it comes in contact with filament materials that are heated at 220 C or above. For high-temperature filaments like ABS or Nylon, other support materials have better compatibility.

Quickly breaks down over time

The solubility of PVA in water makes it very unsuitable as a standalone filament. Any object made with PVA will break down over time simply because of the moisture content in the air. If you need PVA to last a long time, you’ll have to store it inside an airtight container.

Requires a dual extruder printer

There’s a crucial element that is often glossed over when discussing the compatibility of PVA as a support material for other filaments – the fact that this will only work if your printer has dual extruders. A dual extruder 3D printer can print using two different filaments at the same time. If your printer only has a single extruder, then you simply don’t have an option of printing support structures made of a material different from the main project.

8. HIPS

High-Impact Polystyrene (HIPS) is a graft copolymer that combines the two best qualities of its constituent parts – the toughness of polystyrene and the flexibility of polybutadiene. The result is one of the more resilient plastics with excellent impact resistance, strength, and machinability.

However, HIPS has a completely different value in 3D printing. Like PVA, HIPS is mostly used as a support material. This is because of the solubility of HIPS in limonene, a solvent that’s fairly accessible and easy to use. Unlike PVA, though, HIPS has better compatibility with filaments that print at high temperatures.

PROS

Prints at high temperature

The optimal printing temperature of HIPS is at around 220 C to 250 C, with possible slight variations depending on the manufacturer. This makes HIPS an excellent choice for support material for filaments that print at around the same temperatures, including ABS, PETG, and Nylon. Unlike other filaments, HIPS will not deform when it comes in contact with filaments printed at elevated temperatures.

Dissolves in limonene

The value of HIPS as a support material is founded on its solubility in limonene. This is an inexpensive, easily accessible, and generally safe to use solvent derived from the skin of lemons. An ABS print made with HIPS support structures only needs to be soaked in limonene for up to 24 hours for HIPS to fully dissolve. This removes all the extra work and risk of having to cut or scrape off support structures.

Can be used a standalone filament

The similarity of HIPS with ABS doesn’t just stop at the printing temperature. In terms of tensile strength, hardness, and density, HIPS can pretty much stand shoulder-to-shoulder with ABS. This means that HIPS is a perfectly fine standalone filament with good mechanical properties and heat stability. It has a lot more robust applications than PVA, given that it takes a special solvent to dissolve HIPS.

CONS

Prone to warping

Like any other high-temperature filament, HIPS is also prone to warping. Whether you’re using it as the main filament or as a support material, you will need to take the usual anti-warping measures such as using a heated print bed, applying an adhesive to the bed, and enclosing the print chamber to maintain elevated temperatures.

Emits styrene while printing

When heated, HIPS releases fumes of styrene, one of its constituent compounds. While the toxicity of styrene, we still don’t recommend allowing it to accumulate in an enclosed space. In any case, the smell of styrene fumes can be very irritating to the respiratory system. If you’re printing with HIPS, make sure to do it in a well-ventilated room and to wear breathing protection if you need to work closely with the 3D printer.

Requires a dual extruder printer

Much like PVA, HIPS can only be used as a support material if your 3D printer is equipped with dual extruders. Unlike PVA, however, HIPS has value outside of being just material for support structures.

9. Polypropylene

Polypropylene (PP) is considered one of the most widely used commodity plastics in the world. It is a robust material with very high chemical resistance and heat resistance. Despite widespread use, the utility of PP as a 3D printing material is very limited because of its challenging nature. 3D printed PP products, however, are considered some of the most durable.

PROS

Excellent strength and impact resistance

PP is an extremely rugged material that is used for heavy-duty applications such as underground pipes, large plastic sheets, and industrial storage tanks. For rapid prototyping, PP is considered one of the best choices for the production of customized functional models and replacement parts.

Heat-resistant and chemically stable

The chemical structure of PP can be described as being mostly made of a straight chain of carbon atoms with saturated bonds. This gives PP an exceptionally high level of stability against degradation via heat or chemical reactions. PP is heavily used in food storage and medical devices because of these attributes, as it can be safely sterilized by autoclave. In industrial settings, PP has also been used for chemical storage. Combined with its mechanical properties, its heat and chemical stability makes PP one of the hardiest materials that can be used for 3D printing.

CONS

Prone to warping

PP prints at temperatures between 210 C to 230 C. Being a high-temperature filament, PP is similarly prone to warping. Unlike amorphous plastics, the crystalline structure of PP hinders it from “flowing” into porous spaces, thus magnifying the effects of warping. This increases the thermal stress that becomes accumulated within the material, making it more likely for a PP print to retract from its original shape during cooling.

Extremely poor bed adhesion

PP is known as having very low surface energy, making it difficult to get anything to stick to its surface. Unfortunately, this also means that it can be hard for PP filament to stick to the print bed. This increases the chances of warping of a PP print, manifested as the corners of the base layer getting lifted up.

This is one of the reasons why PP is considered one of the most challenging filaments to work with. To succeed with a PP print, you may need to combine a bed adhesive with a brim or raft to get it to stick to the bed. There are also specially designed build plates made out of PP to take advantage of the fact that similar materials will stick to each other with little difficulty.

10. PEEK / PEI

Polyethyl Ether Ketone (PEEK) and Polyether Imide (PEI) are two different filament materials but they are similar enough to each other that their advantages and drawbacks can be discussed together. Both PEEK and PEI fall under the Polyaryletherketone (PAEK) chemical group, which is well known for superior mechanical strength, heat stability, and chemical resistance. PAEK are also ideal materials for 3D printing as they do not emit toxic fumes when heated.

Both PEEK and PEI are commonly used as lighter and cheaper alternatives to aluminum and other metals.

PROS

Good rigidity and strength

Even compared to traditionally robust filament 3D printing materials like Nylon or PETG, the mechanical properties of PEEK and PEI are at a completely different league. There are several good reasons for why the 3D printing community refers to PEEK and PEI as “high-performance” filaments.

To demonstrate it by numbers, Nylon typically has a tensile strength of 34 MPa and Young’s modulus of 0.6 GPa. PEI, on the other hand, has a tensile strength of 85 MPa and Young’s modulus of 3.2 GPa. PEEK has even higher values – tensile strength of up to 100 MPa and Young’s modulus of 3.6 GPa.

Thermally and chemically stable

The printing temperature of both PEEK and PEI is about 100 C higher than that of ABS. While this has consequences on the compatibility of these filaments with standard 3D printing equipment, it also means that PEEK and PEI prints can withstand much higher temperatures without experiencing deformation.

PEEK and PEI can resist attacks by acids, bases, and oils. They also do not degrade under UV radiation. This degree of robustness makes PEEK and PEI suitable for projects intended for outdoor use.

CONS

Requires very high printing temperatures

PEEK and PEI print at temperatures that range between 360 to 400 C. This is way higher than the 230 C of the usual 3D printing filament that we’ve come to know as “high-temperature.” This immediately eliminates PEEK and PEI as viable filament materials for many desktop 3D printers.

Even upgrading a standard 3D printer to make it compatible with PEEK or PEI can be a huge undertaking. Not only will you need to replace the heating element of both the nozzle and the heating bed, but you will also need a thermistor that can detect temperatures up to 500 C and a cooling mechanism for the various stepper motors in a 3D printer. You will likely also need to reposition some of the electronics of the printer, especially if they aren’t meant to be exposed to extreme temperatures.

Requires extraordinary measures against warping

Warping is still an issue with PEEK or PEI, but they no longer present an issue that can be solved with standard adhesives and chamber enclosures. For instance, NASA had to install 35W halogen light bulbs on a modified LulzBot TAZ 3D printer to keep the print chamber warm enough so that the PEI material does not warp. The chamber itself will also have to be heavily insulated.

Limited availability

Between PEEK and PEI, it will be easier to buy PEEK filament. It’s been around for quite some time, primarily because it is also being used in 3D printing via Selective Laser Sintering (SLS) technology. There’s also a good selection of PEEK variants in the market with different additives and properties.

Just about all PEI filaments in the market come from the ULTEM brand. This means that you’re likely going to end up with filament coming from the same resin no matter where you buy the filament.

Expensive

A 1-kilogram spool of either PEEK or PEI will set you back several times more compared to standard ABS or PLA filaments. The difference between the two is also stark – a 1-kilogram spool of PEI costs around $100, while a similar weight of PEEK will cost up to $500. At these prices, it’s really no wonder why we rarely see PEEK or PEI being used for casual 3D printing

11. Amphora

What makes Amphora unique as a filament that it was not manufactured based on a polymer that already exists. Instead, Amphora was based on a custom polymer specifically created by American firm Eastman Chemical Company back in 2013. Even today, Amphora remains the only custom polymer used in FDM printing.

The Amphora filament was designed to have the most desired characteristics as some of the more common 3D printing filaments – the durability and stability of ABS, and the flexibility of TPU. The result is a uniquely strong filament that is tough but not brittle and has an excellent layer to layer adhesion.

PROS

Strong and flexible

Amphora is one of the best choices for all-around durability. It’s just about as strong as ABS, as well as chemically and thermally stable. However, it also allows a small amount of “yield” similar to TPU. This means that an Amphora print can slightly deform as a reaction to applied forces, making it less prone to cracking or breaking under stress.

Good bridging performance

TPU is known as having notoriously poor bridging performance because of how soft it is, even when cooled. Amphora acts as a good compromise. It retains some of the TPU’s flexibility but has massively improved bridging performance. Features made in Amphora can extend up to 15 centimeters with no supports without collapsing, although we suggest keeping them to only 8 centimeters for safety.

Safe for food contact

Amphora is one of the few 3D printing materials that have been FDA-approved as safe for food contact. This is great if you want to manufacture customized kitchen tools. However, we still discourage using any kind of 3D printed object for long-term food storage. The microscopic imperfections on the surface of anything printed with FDM technology are almost impossible to clean and can act as a breeding ground for bacteria.

Less tendency to warp

Although Amphora at temperatures that are comparable or higher than ABS or Nylon, it does not warp quite as easily. This does not mean that you can print with Amphora with no heated bed or adhesives – those will still be necessary. However, Amphora is not as finicky. It’s even possible to print with a cooling fan when using Amphora filament.

CONS

Expensive

Despite being in the market for a couple of years, the rate of adoption for Amphora filament has been quite poor. The cost of the filament probably plays a huge role – Amphora costs around $50 to $60 for a 1-kilogram spool. While Amphora is far from being the most expensive filament around (PEEK and PEI cost more, for instance), the steep price is enough to repel those who just want to go into 3D printing as a hobby.

High printing temperature

Amphora prints at around 250 C to 270 C. Although we’ve mentioned that Amphora does not have as much of a warping problem as many other filaments that print in this temperature range, that still does not discount the fact that not all 3D printer models can handle Amphora.

12. Composite filaments

Composite filaments are a bit harder to define, as the term can be used to describe more than a dozen different filament types. In virtually all cases, a composite filament is one that is made with a solid powder embedded in a plastic matrix. The objective of a composite filament is to create a 3D printed object that mimics the appearance of a material that is traditionally not used in 3D printers.

PLA is often the material of choice for the plastic matrix, owing to how easily it can be used. The solid powder component, on the other hand, can range from wood, metal, carbon fiber, glow-in-the-dark fragments, or marble. There is a huge variety of composite filaments out there, with some brands seemingly trying to make filaments that are as exotic as possible.

PROS

Superior aesthetics

While 3D printing is an amazing manufacturing technique, there comes a time when the usual “plastic” appearance of 3D prints can get old. This is the main appeal of composite filaments – it allows you to make 3D printed objects that look like they were made of metal, wood, or about a dozen other materials. The quality of the output may vary from one filament to another, but there’s no doubt that they are refreshing and add a whole layer of possibilities to what standard FDM printers are capable of.

Wide finishing options

Almost as varied as the types of composite filaments are the options for how they can be finished. Each material responds to finishing techniques in different ways. For instance, prints made with wood filaments can be sanded smooth and stained to highlight the artificial grains created during the printing process. Prints made with metal filament can be sanded with rough sandpaper to partially reveal the metal powder. The powder can be oxidized by soaking the print in water to give the finished print a weathered look.

CONS

Brittle filament

The addition of solid powder to PLA results in the filament losing a lot of its flexibility. When handling composite filament, be wary of the fact that there’s a real possibility of the filament snapping in two if it gets bent too much. This means that you’ll have to make sure that the filament follows a pretty smooth path that is free from sharp turns from spool to extruder.

Accelerates wear on the nozzle

The presence of solid powder also makes composite filament much more abrasive. This accelerates the wear and tear on just about all the components of a 3D printer that comes in contact with the filament, but it most quickly manifests in the nozzle. Friction between the hard powder of the filament and a stock brass nozzle will result in the nozzle opening gradually getting larger.

If you’re printing with composite filaments, you might want to invest in a new wear-resistant nozzle. A wider nozzle opening will also help reduce the abrasive forces created by the filament.

Poor bridging performance

Another effect of the presence of solid powder in the filament is that it makes the filament much denser. The added heft feels nice on a 3D printed project but can be a small inconvenience during printing, especially if the model has a lot of overhangs.

Bridging and overhangs are already problems in standard filaments, but the added heft of composite filaments makes the problem worse. A cooling fan running at maximum speed might help mitigate this problem by allowing the filament to develop strength as quickly as possible. However, most situations will likely call for support structures. Luckily, you can always use water-soluble PVA if your 3D printer comes with dual extruders.

Final thoughts

Whether FDM-based 3D printing is simply your hobby or if you’ve made a professional career out of it, there’s no doubt that you’re spoiled for options when it comes to filament materials. Nowadays, you can take your pick from more than a dozen different filament types or even choose from a range of different variants of the same filament. This has sparked the creativity of many and has made FDM printing an even more appealing activity.

As long as this list turned out to be, the filaments we’ve included here are only those that we consider the basic or fundamental ones. Some options are far less common and more exotic. As technology evolves and more innovative minds get involved, we can expect even more filament types to be developed.

“When heated, HIPS releases fumes of styrene, one of its constituent compounds. While the toxicity of styrene, we still don’t recommend allowing it to accumulate in an enclosed space.”

My brain tried to add two words to make sense of the second phrase : While the toxicity of styrene is low, we still …