How to Reduce Power Costs When 3D Printing

Shortening the printing time is the single most effective method for reducing the power costs associated with 3D printing. You can also try and optimize heat control by printing inside an enclosed chamber. In any case, the power cost of a 3D printer and quite small compared to typical household devices.

When you get a 3D printer, it is inevitable that your power costs will go higher. This becomes more important if you tend to run your 3D printer for more than 12 hours a day, or if you have two or more 3D printers running simultaneously. What can you do to lower the power expenses of 3D printing?

How a 3D printer consumes power

For us to identify areas in which we can cut a few corners in terms of power consumption, we must first identify which operations of a 3D printer are most power-intensive. A 3D printer has a lot of moving parts and involves heating components to very high temperatures. Under the hood, there is also a lot of data and command processing that goes into controlling the various parts of a 3D printer. All of these processes consume power to different degrees.

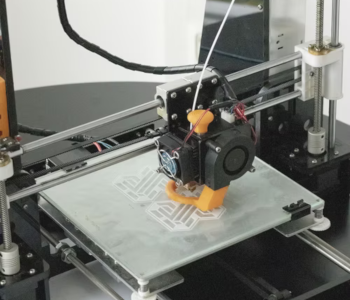

Hot end

The hot end of a 3D printer is responsible for melting the filament so that it can be extruded through the nozzle. Depending on the filament you’re working with, this hot end will have to reach temperatures of 240 °C or even higher. It is absolutely critical for the hot end to maintain this temperature, likely making it one of the most power-intensive parts of 3D printing.

Heated bed

Heat also plays a huge role in the print bed of a 3D printer. A heated bed is necessary for printing with filaments at high temperatures, especially those that are prone to warping. Again, the temperature of the heated bed needs to be maintained throughout the whole 3D printing process. This becomes considerably harder for printers with large print beds.

Cooling fans

There are two cooling fans in 3D printers. One is the fan for the heat sink of the hot end that prevents heat from creeping beyond the melt zone. The other cooling fan is for the part being 3D printed.

The first cooling fan is non-negotiable. It is an important element in ensuring the proper function of the heat sink. A failure in the heat sink fan can lead to deterioration of the PTFE tubing and various extrusion issues. The cooling fan for the part is optional. When printing with filament that is prone to warping, it is often best to not use the cooling fan at all.

Stepper motors

A 3D printer has several stepper motors that control the movement of several parts such as the print head, the print bed, and the extruder. These stepper motors have to be running for the entire 3D printing process. They are quite small, though, and do not consume a lot of power.

Control board

The control board is the “brain” of the 3D printer. It is responsible for making sure that the heating elements are at the proper temperatures and that the moving parts move according to the commands from the G-Code. This is, of course, one of the most important parts of a 3D printer. The control board is typically just a single printed circuit board to which all the electrical components of a 3D printer are connected.

Display

Almost all 3D printers today have some sort of LCD or LED visual display. This interface provides a small degree of control to the user. It also displays critical 3D printing parameters such as temperature, print speed, and estimated printing time. These display devices are incredibly efficient and use up a negligible amount of power, even if they have to be activated for the entire duration of the project.

With this knowledge of how a 3D printer uses power, we can have a better idea of how power usage can be reduced. We can either cut a few corners here and there, or just focus our attention on one or two major contributors.

Ways to reduce 3D printing power consumption

Some components of a 3D printer leave hardly any room for adjustment. For instance, the stepper motors will have to run throughout the entire process, no matter how many tweaks you make. The control board and display consume so little power that they have very little influence on the power consumption of the entire 3D printer. This simply means that we can easily narrow down the viable methods for reducing power usage.

Reduce heat loss

Heat plays a huge role in 3D printing. Unfortunately, heat also naturally dissipates to the environment. No matter where you put your 3D printer, its surroundings will always be colder than the hot end nozzle and the heated bed. If you can control this heat loss, then that would be a huge help in reducing power consumption.

The best solution is to create a “mini-environment” that can retain some of the heat from the high-temperature components. This simply means building an enclosure around the printing chamber of your 3D printer. If your 3D printer already has such a feature, then it’s probably already operating more efficiently than many other 3D printers.

Reduce printing time

Another strategy worth exploring is to reduce the total printing time for your project. If a model can be printed quickly, then it certainly will use up less power.

There are several strategies for reducing the printing time for a project. The easiest is to reduce the print speed, although this can have several consequences in terms of quality. You can try reducing the infill density, or using an infill pattern that is simpler or needs less filament. Conversely, you can print with thicker layers or thinner walls.

Take note that for many of these methods, there is almost certainly a trade-off involved. Printing at a lower infill density or thinner walls means that the output will lack some strength. Printing with thicker layers might mean that some of the precise details may not be as clear. Whether these trade-offs are acceptable will depend on the specific circumstance of your project.

Another good strategy to reduce printing time would be to try and fit as many possible models on a single run of your 3D printer. This is a bit of a high-risk/high-reward strategy, as failing means having to start on a monumental project from the start. If you’re very confident with your 3D printer settings and filament, then can consider this technique.

Print at lower temperatures

Printing at very high temperatures will undoubtedly use up more power. You will need to use more power to heat both the print bed and the heating element of the extruder. Heat loss is also more pronounced when the hot elements are maintained at higher temperatures.

Unfortunately, printing at low temperatures really isn’t an option when you’re using a filament like ABS or Nylon. The only realistic option is to use filaments that do not require high temperatures to melt. If the situation allows it, then it really is more practical to stick to good old PLA.

How much power does a 3D printer consume?

Are power costs really something you should be worried about when buying a 3D printer? You would be glad to know that the power consumption of a 3D printer is likely less than what you expect.

Average power draw of 3D printers

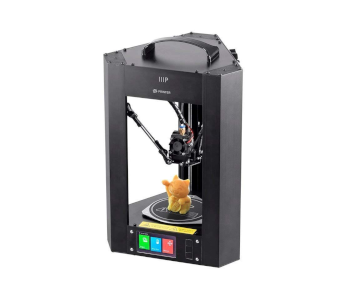

The power draw of 3D printers varies from one model to another. For instance, the Monoprice Mini Delta is a very compact delta-type 3D printer that has an average power draw of about 60 W during operation. It does not have a heated bed, has no enclosure, and uses three stepper motors to control the position of the print head.

In comparison, the Creality Ender 3 has an average power draw of 125 W while it is running. The higher power rating is likely due to the printer having a heated bed. The Ender 3 also has a much higher build volume than the Mono Delta, which means that the print bed also has a large surface area for potential heat loss.

Taking things up a notch is the Flashforge Creator Pro. This premium 3D printer has an all-metal enclosure, heated bed, dual extrusion system, and an illuminated build chamber. The build volume of the Creator Pro is comparable to that of the Ender 3. Despite that, the average power draw of the Creator Pro is an astounding 250 W.

These three printers are a good representation of the range of power rating numbers that you can expect from desktop 3D printers. In terms of kilowatt-hours, the range of 60 W to 250 W translates to 0.07 to 0.24 kWh.

Conversely, you can try plugging your 3D printer through an electricity usage monitoring tool. The Kill A Watt Electricity Usage Monitor is a good option. This device can measure the real-time power usage of your 3D printer and can even calculate the power expenses over a specific time period.

Based on the latest statistics, residential customers in the United States pay an average of 13.31 cents per kWh for electricity. Applying that rate to our sample of 3D printers gives us a cost of 0.93 to 3.19 cents per hour.

How 3D printers compare to other household devices

To provide some context to the numbers we have calculated for the power consumption of 3D printers, it may be a good idea to look at the other appliances or devices in a typical household.

| Device | Power rating |

|---|---|

| 32-inch LED TV | 50 to 70 W |

| Refrigerator | 100 to 250 W |

| Laptop computer | 50 to 100 W |

| Desktop computer | 60 to 250 W |

| Single-room air-conditioner | 500 to 1500 W |

| Space heater | 200 to 1500 W |

As you can see, running a fairly sophisticated 3D printer like the Creator Pro is similar to using a high-end desktop computer or refrigerator. The power draw isn’t so big, especially if you don’t use your 3D printer daily. There will almost certainly be bigger power-guzzlers in your household.

However, making a few adjustments to reduce the power draw of your 3D printer is still worth the effort. If you use your 3D printer 50 hours per week, you can potentially save more than $50 in your electricity bill per month.

Final thoughts

One thing that intimidates many people about 3D printing is the prospect of higher power bills. This will almost certainly happen if you have a 3D printer running for several hours a day. However, there are ways to reduce the power usage of your 3D printer by understanding which parts of the process draw a lot of power.

The good news is that 3D printing isn’t actually as power-consuming as you might have thought it to be. If you just work on one or two projects per month, then the added expenses will be minimal.