Is It A Good Idea to Buy An SLA 3D Printer?

Most people who go into 3D printing out of curiosity start with Fused Deposition Modeling printers. FDM printers are inexpensive, easy to use, and have a large and thriving community of users and experts. There’s also so much to learn about FDM printing that it can take you years to become highly skilled in it.

In contrast to FDM, Stereolithography or SLA printing is perceived to be a little more complex. While this argument still stands, SLA printers are now more accessible and affordable. Is it time to transition to SLA printing? Here are some factors to consider.

The basics of SLA printing

In contrast to the filaments used in FDM printing, the raw material used in SLA is photopolymer resin. This is a liquid solution that almost instantly becomes solid when exposed to UV radiation. This is a very fast process compared to filament-based printing and results in more highly detailed prints. On the flipside, printing with resin can get quite messy and is a little more expensive.

Although SLA is an older 3D printing technology than FDM, it has not quite enjoyed the same level of mainstream popularity. It’s not very beginner-friendly, and there was a time when you SLA printers were used mostly in industrial and commercial settings.

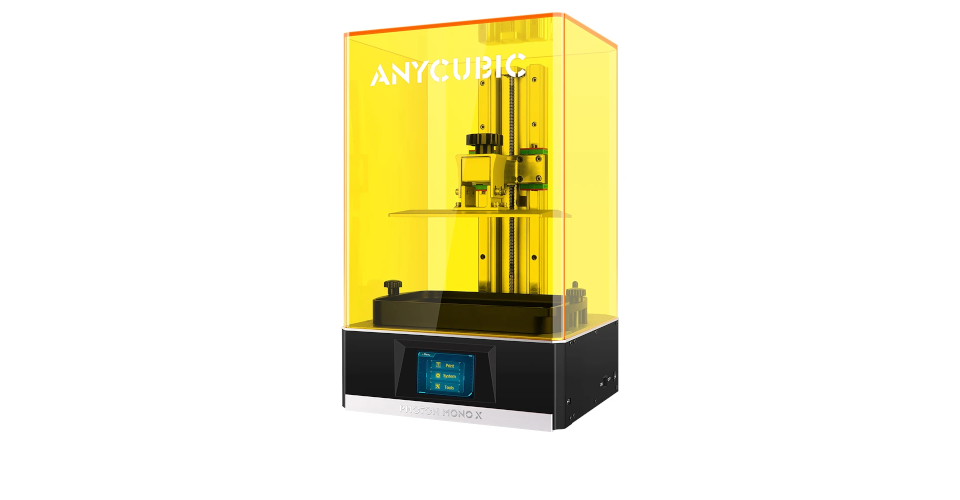

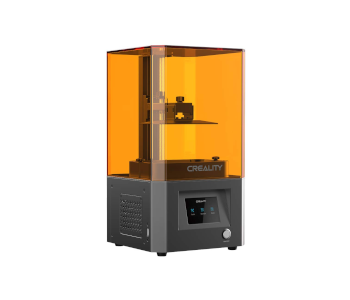

However, times have been changing in favor of SLA printing. Nowadays, you can buy desktop SLA printers from popular brands like Anycubic and Creality. They are also quite affordable – you can probably get one for less than $300. This trend has made more and more 3D printing enthusiasts consider shifting to SLA printing.

Design considerations

SLA isn’t the appropriate technology for all kinds of 3D printing models or projects. There is no doubt that SLA printing is beneficial when done right, but it is by no means an option that is superior in every aspect. Before making the move to SLA, know that it also has limits.

Small build size

Compared to an FDM printer with a similar footprint, an SLA printer would likely have a much smaller build size. This is part and parcel of how SLA printers work – instead of just a build plate, it also has a containment vat for the liquid resin.

For this reason, SLA printers are typically used for miniatures and other small projects. Yes, there are SLA printers that are capable of larger build sizes. However, there are expensive and typically only used in industrial settings.

Suitable for precise details

One strong suit of SLA printing is resolution. Instead of a nozzle, the limiting factor in the resolution of SLA printing is the size of the UV laser. This is a lot smaller, making it suitable for highly detailed projects. SLA printing has become a favorite in the miniature-making industry exactly because of how impressively precise the technology is.

Limited resin selection

Although SLA printing is slowly gaining popularity, it’s nowhere near as ubiquitous as FDM printing. Users of FDM printers are spoiled for choices. On top of a wide range of filament colors, you have filaments that glow in the dark or simulate the appearance of wood, ceramics, or different types of metals.

Resins don’t have as wide a range of options. In fact, most 3D printing resins are either gray or black. This isn’t much of a problem if you plan on painting your SLA prints.

Poor bridging and overhang performance

Bridges and overhang features are usually problematic in additive manufacturing. In the case of FDM, there is a bit of tolerance as dictated by the 45-degree rule for overhangs. SLA prints do not fare quite as well. In fact, many would go so far as to say that SLA prints have virtually zero tolerance for overhangs and bridging.

This only means one thing – if your model has a lot of overhanging features, then you will have to print with lots of supports. This adds even more work to what is already a tedious post-processing phase.

Drainage holes are essential

Another consideration when designing a model for SLA printing is the addition of drainage holes. Why are these important? As with FDM printing, prints made via SLA aren’t printed solid – they have an internal cavity that can be filled with your chosen infill pattern and density.

Since you’re working with a liquid raw material, this internal cavity will inevitably contain residual uncured resin. To remove this resin, there must be a way for it to drain out. This means that some models printed in FDM might need to be revised a bit before they are appropriate for SLA.

If you own an FDM printer, then we suggest that you consider keeping it around even when you get yourself a new SLA printer. Each option has its strengths. SLA printers are excellent for printing highly detailed models but are hardly practical if you’re just printing a vase or a replacement bracket for your broken door.

Differences in workflow

By now, it should be fairly obvious that the SLA printing process is very different from FDM. Yes, you will still be loading a 3D model into slicer software, but the differences pretty much end there. Here are the changes you should expect:

Requires careful handling

Uncured resin can be toxic if it comes in contact with your skin or eyes. The actual 3D printing process also emits toxic and irritating fumes. For all the safety precautions that are recommended for FDM, SLA printing will demand even higher safety standards. When working with resin, make sure to use nitrile or neoprene gloves as well as safety goggles and some respiratory protection. Keep your 3D printer in an area with good, constant ventilation.

If you have any leftover uncured resin, then you also need to treat it as a toxic material. This goes as well for containers with residual as well as the isopropyl alcohol used during post-processing. You have two options for proper disposal – to call up your local recycling facility to check if they can handle the resin or to cure it under the sun. Take note that the curing process can take up to a week if you just do it via sun exposure.

More post-processing work

The post-processing work for SLA prints can be very messy and tedious. Yes, SLA prints come with less visible layer lines and finer details, which means they don’t need to be sanded or polished quite as heavily. However, getting to that point is another process in itself.

When an SLA print comes fresh off the printer, it will likely be dripping with excess uncured resin. This thick resin will have to be washed off (preferably with isopropyl alcohol), lest they mess up the look of the finished print. Make sure to follow the guidelines for disposal of the alcohol and resin solution.

If you printed with supports, now would be the best time to remove them as they should still be quite soft. Take note that the rest of your finished print will still be partially soft, so you need to be very careful with support removal. We find that the best tools for this job are a knife and some extra long tweezers.

The SLA print will then need to go through post-curing to develop its maximum strength. This can be done either through a special UV chamber or by placing it under a free source of UV radiation – the sun. Sun exposure is free but will take about a week for complete post-curing. Ready-made UV chambers can cost upwards of $500.

Conversely, you can just buy a UV light and make your own UV curing box. There’s even a free design on Thingiverse for one.

The costs of SLA printing

As mentioned, SLA printers are no longer as expensive as they used to be. However, this is not the only additional cost you need to anticipate. There are supplies and auxiliary equipment that are unique to SLA printing. To make sure you’re financially prepared for an SLA printer, here are the major cost drivers to consider:

The SLA printer

If you’re just starting out, we suggest going for an entry-level desktop SLA printer such as the Anycubic Photo Mono or the Creality LD002R. These cost less than $300 and are fairly popular in the 3D printing community. Of course, you have the option of going for a higher-end (and more expensive) model such as the Anycubic Photon Mono X which is faster and has a larger build size.

Photopolymer resin

Resin for SLA printing is typically sold in 500-gram bottles, each costing around $20. Volume-wise, this is more expensive than the filament used in FDM printing. Also, worth noting is that a lot of this resin will inevitably go to waste when washed with isopropyl alcohol. If you’re just starting out, then it would be a good idea to buy at least three or four 500-gram resin bottles and see which one works best for you.

Isopropyl alcohol

You will need isopropyl alcohol to rinse off the excess resin after SLA printing. The general rule here is the stronger, the better. If you can get your hands on 99% isopropyl alcohol, then it would be a bit more potent than a 70% solution.

If buying isopropyl alcohol is difficult right now because of the pandemic, it’s actually perfectly fine to use ethanol instead. Regardless of which type of alcohol you use, make sure to let it evaporate fully after rinsing before proceeding to the post-curing step. Otherwise, your finished print could end up with a permanent white residue.

UV curing box

The last step of the SLA printing process is post-curing. This simply completes the curing of the resin so that it develops maximum strength. You can buy an inexpensive UV curing box for less than $100, like this one from Sunlu. Anycubic and Elegoo also sell kits that contain both an alcohol washing station and a UV curing box. These are more convenient but also a little more expensive – they cost just a bit above $100.

The cheapest option would be to buy a UV lamp and make your own UV curing box. You can download free 3D printable models online. UV lightbulbs are very cheap. You should be able to get a two-piece bundle for less than $20.

All things considered, you should be able to set up an SLA printing station for about $500. This is assuming that you’re getting an inexpensive desktop-scale SLA printer.

Final thoughts

A lot of 3D printing enthusiasts who have gotten accustomed to FDM printing continue to be intimidated by the prospect of transitioning to SLA. Aside from the cost of getting new equipment, you will have to re-learn a few skills.

The good news is that SLA printing is now a lot more accessible. SLA printers and auxiliary equipment are cheaper. As more people get into SLA, there should now be more communities that can support beginners.