STL Repair Software: Why You Need It and Best Options

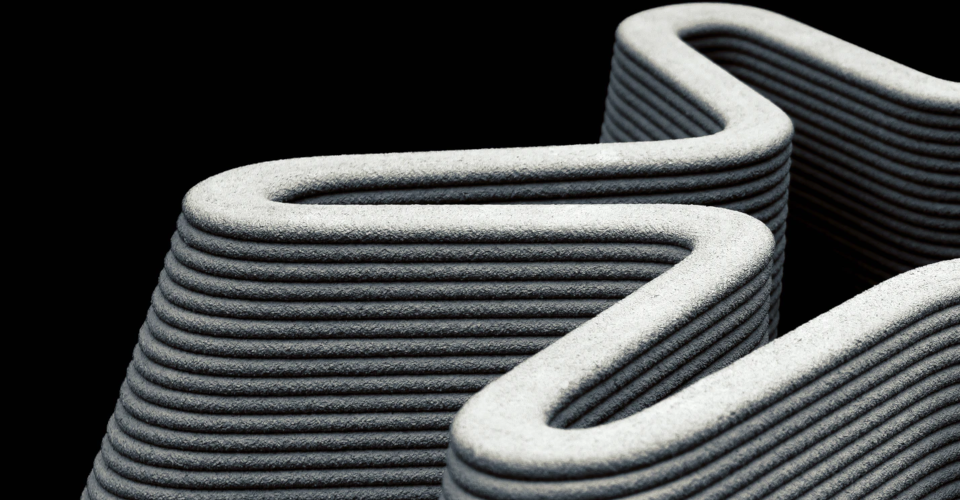

The STL file format is ubiquitous in the field of 3D printing. STL stands for ‘Stereolithography’ and is a file format the represents a 3D surface using a series of tessellated triangles. This simplification of 3D surfaces makes STL files particularly suited for sharing and publishing 3D models for printing.

However, printing an STL file may not always be as simple as downloading it and running it in your 3D printer. Some of the data get lost in translation, requiring the use of software for STL repair. What is an STL repair software and is it really necessary? What are the best options for STL repair software out there?

Why you need to repair STL files

Every error that can come up in an STL file comes from its fundamental concept of representing a smooth 3D surface using a high number of tessellated triangles. Ideally, the edges of these triangles line up perfectly to form an airtight surface. Problems ensue when this is not the case.

There are three common errors in STL files that could lead to problems when it comes to print them:

Boundary edges

This is an error where the edges of the triangles in a 3D model don’t line up perfectly in such a way that they leave gaps or holes on the surface. This typically happens when the edges of triangles in an STL file are connected to more than one face in their neighboring triangles. In essence, the model is no longer airtight.

Intersecting faces

Intersecting faces occur when the edges of the triangles are not perfectly lined up that they result in some of the triangle faces overlapping with each other. While a 3D model can still be airtight even if it has intersecting faces, this error leaves ambiguity to what the model should look like.

Over-refined mesh

This is the least serious of the STL errors and only happens when the total number of the tessellated triangles in the model exceeds the capability of the 3D printer. This also unnecessarily bloats the file size of the STL model, making it harder to share with a level of detail that is no longer practical.

What happens when you try to print STL files with errors?

Your slicing software should be able to detect any errors in your STL file as soon as you load it. Some slicing software platforms could even impose remediation measures if you don’t feel like repairing your STL file. However, the outcome of trying to print an STL file that has errors is unpredictable at best. Any of the following could happen:

- The file will not print at all

- The finished print will have missing faces

- The slicer software will automatically fill in the gaps in the model with flat surfaces

- The model will print but with poor resolution

- The finished print will have inaccurate features

While it’s entirely possible to proceed with printing an STL file that has errors, you will almost certainly not end up with a print that looks the way that it was meant to by the designer. In most cases, this inaccuracy is bad enough for the finished print to be deemed unusable.

If you don’t want to end up wasting your filament and the time spent printing, then we recommend repairing any errors in your STL file before loading it onto your 3D printer.

Top 5 recommendations for STL repair software

1. Microsoft 3D Builder

If you’re a Windows user, then there are a lot of good reasons to consider Microsoft 3D Builder for your STL repair needs. In fact, you may already have it on your computer, as it comes pre-installed with Windows 10. It’s pretty well-known with 3D printing enthusiasts because it’s easy to use and free to download for Windows users.

As its name implies, Microsoft 3D Builder is a fully functional 3D modeling software platform. Its repair function is convenient because it’s a single-button command, although many users have indicated that it doesn’t work all the time. It also doesn’t receive a lot of support from Microsoft, so its features very rarely get updated.

As a 3D modeling platform, Microsoft 3D Builder is far from the best. While the app is capable enough if you’re a student or if you’re just doing 3D modeling for fun, it’s mostly made for downloading pre-built models and cleaning them up in preparation for printing.

Another major limitation of Microsoft 3D Builder is that it only exports 3D models in the 3MF (3D Manufacturing Format) file format. This is an open-source format developed by Microsoft that is designed to hold more information than STL or OBJ files. While the file format itself seems excellent, not all 3D printers may be compatible with it.

2. Netfabb

Netfabb by Autodesk is another excellent all-around 3D modeling software with an easy repair function. Unlike Microsoft 3D Builder, this is a professional-grade platform that was made specifically to aid in additive manufacturing applications. This is a very powerful tool and should serve you well beyond just repairing your STL files.

The Repair Tool in Netfabb should cover just about any type of error that can come up in your STL file. Simply run the Repair script to automatically repair any detected errors. If the basic Repair function doesn’t work, you can try the more complex Extended Repair process. Netfabb also has an optimization tool to minimize the file size of models with over-refined mesh.

Since Netfabb has no proprietary file format, you can export the repair models as STL files.

The biggest hindrance to the widespread use of Netfabb is its price. Although Autodesk offers a 30-day trial for Netfabb Premium, the actual subscription rate costs a whopping $4200 per year. This is probably way too much if you’re just into 3D printing as a hobby.

Compatibility might also be a problem with Netfabb, as it’s now exclusive to Windows. Users of Linux or macOS can still download an older version of Netfabb via an unofficial GitHub repository, but the functions of these older versions may be limited.

3. MakePrintable

MakePrintable is an online platform that is specially designed for the repair and optimization of 3D models. This is one of the more versatile 3D printing services in this list, making it a viable option for both hobbyists and professionals.

In terms of repair performance, the performance of MakePrintable is impeccable. Since STL repair is their primary specialty, they offer a host of repair functions that should solve any errors in your STL files, whether it’s gaps in the model or features with zero thickness.

What makes MakePrintable an interesting option is their wide range of pricing options. You can sign up for the subscription plans which start at $14.99 per month with each package offering a different number of repaired files and range of repair functions. Even their premium subscription plan, which costs $99.99. per month, is significantly cheaper than other 3D modeling services.

For those who don’t want to get locked into a financial commitment, MakePrintable also offers a Pay Per Download scheme. Simply upload your file, repair it using the browser-based interface, and pay $2 to download the repaired file. This is probably one of the cheapest ways to get your STL files repaired using professional-grade tools.

4. Blender

Anyone who’s had an interest in 3D modeling has probably heard of Blender. This is because Blender has been around for more than two decades and is still considered the standard open-source 3D modeling and animation software.

As you can tell from that statement alone, Blender is capable of much more than just repairing your STL files. It offers a full suite of tools for the creation of 3D content which has been developed through the years by a very active community. Since the software is open-source, you can download it for free and can even modify it for your needs.

Blender’s Repair Tool isn’t exactly “one-click” like the other software platforms in this list. You’ll need to go through a somewhat convoluted process, especially if you haven’t used Blender before. In terms of the degree of control you have over how your repaired files will look like, however, Blender is pretty hard to beat.

The thing about Blender is that it’s absolutely not beginner-friendly. With tools and functions that have been developed through the decades, the appeal of Blender is that you can do just about anything with it. If you’re thinking of leveling up your 3D modeling skills eventually, then overcoming the learning curve of Blender may be well worth the effort.

5. Sculpteo

Lastly, we have Sculpteo, an online service that will 3D print your models for you. Sculpteo remains the best option for those want to create 3D prints but don’t have their own 3D printers. The advantage of using Sculpteo is that you’re certain to get professional-grade output without having to make a huge investment in buying your own equipment.

Scuplteo isn’t exactly an STL repair software platform. However, their service requires you to upload a 3D model on their website. Their site’s interface has repair tools for STL files that are specially designed for specific use cases. Whether your model is meant for architectural use, miniatures, or CAD modeling, you should be able to repair it easily with prepared algorithms.

The online platform of Sculpteo is a very convenient tool for repairing STL files but it has one major flaw: you can’t download the repaired STL file for your personal use. Instead, it needs to be submitted to Sculpteo for printing.

Final thoughts

STL has pretty much become the standard file format for sharing and publishing of 3D models for 3D printing. Despite all its limitations, it’s still heavily used because it’s a uniquely lightweight file format.

However, the integrity of 3D models in STL form often becomes compromised when they get passed around. Even the mere act of exporting a 3D model as an STL file can result in minor damage to the model. For this reason, repairing is an STL file that should be considered a precursor to the printing process. The list we’ve come up with should give you good options for STL repair no matter what your use case, budget, or goals are.