The Kraken Dual Pinch Wheel Extruder For 3D Printers Launches On Indiegogo

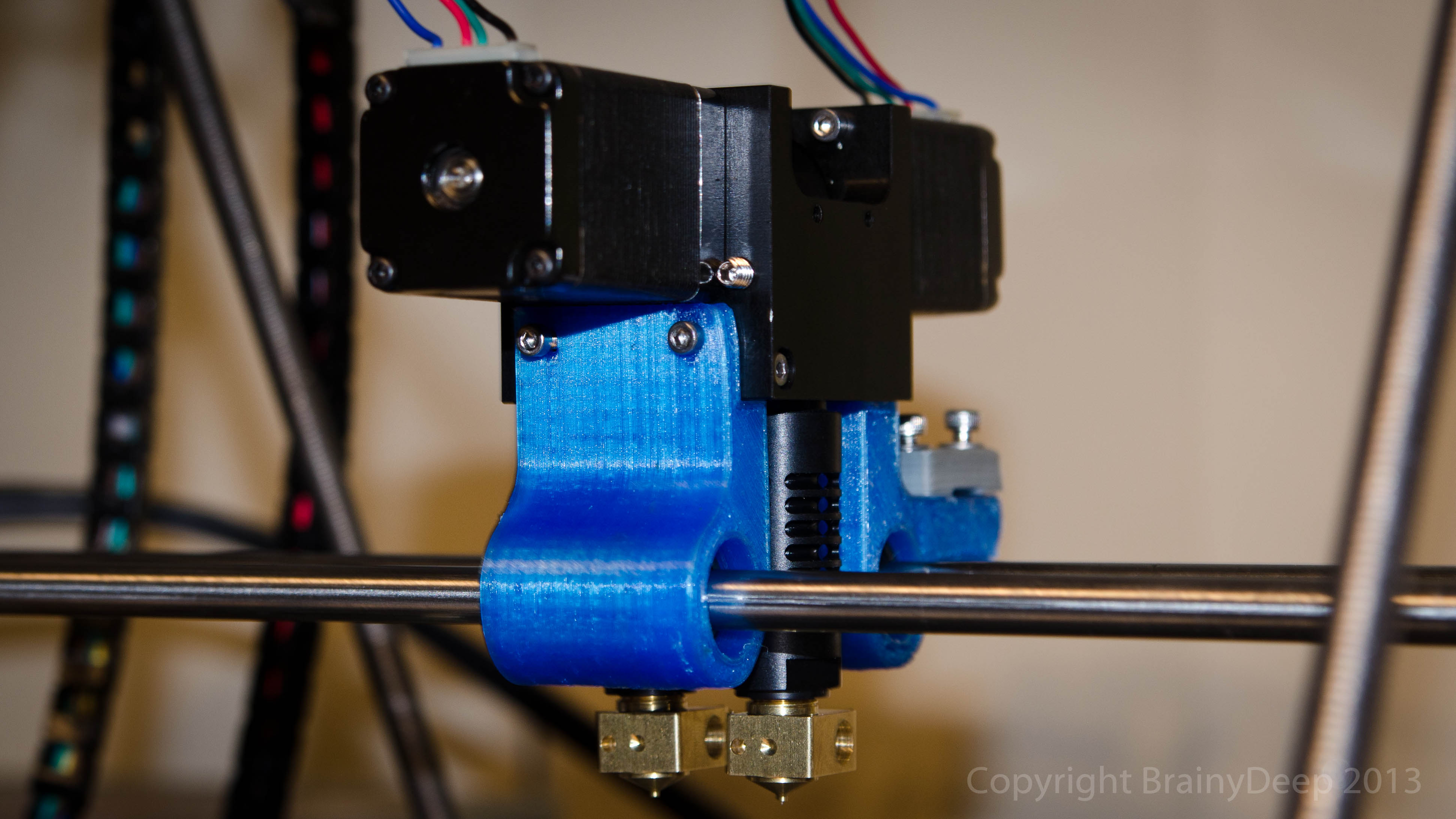

Australian based start-up BrainyDeep claims their Kraken Dual Pinch Wheel Extruder is the first of its kind and is also the smallest duel nozzle extruder available. They believe that their extruder is the best extruder in the world and can even rival some commercial machines.

The Kraken’s duel pinch wheel mode uses both motors on the Kraken to drive one filament line. This allows greater control and grip on the filament over conventional extruder’s. It also reduces the chance of stripped out filament and increases the extrusion force which can be achieved.

Kraken’s extrusion rate has been clocked at 900mm/s with no filament slip. The higher forced extrusion rate means that the extruder can operate at lower temperatures for faster material setting times and less warping.

Another feature of the Kraken is its duel nozzle extruder. At only 40mm wide, the Kraken is the smallest duel extruder on the market and you can have 4 nozzles in less than the size of one Wade’s Geared extruder. The nozzles are located closer to each other so each nozzle can reach more of the build platform. One nozzle can print up to to 26x20cm, 23x20cm with two nozzles and up to 15x20cm with four nozzles on a standard build Prusa Mendel.

Features include:

- Unique Mechanism with Huge Gear Ratio (20:1)

- Extrusion rate control – The gearing means each motor step is now smaller than ever before, giving better control of filament deposition rates! We’ve tested down to 0.02mm layers at 30mm/s!! (0.36mm^3/s)

- Smaller Lighter Motors – Using NEMA 11 motors, only 28mm square, only 140g and only 0.6 amps each!

- Small Size – 41.2mm wide, ~90mm tall – Print larger than you thought possible on your current chassis!

- Increasing Tangential Force – Filament force increases with increasing speed, for perfect printing across the widest range of printing conditions. Over 300:1 ratio between the fastest and slowest tested extrusion rates!

- Step Loss, not Filament Strip – Step loss rather than stripping the filament – step loss will recover, stripped filaments will not – the difference is a minor blemish instead of an aborted print.

- Suits all filament sizes – Using different filament sizes is as easy as just swapping your J head!

- Metal design – Machined chassis is compatible with any high temperature hot end designs with a J head mount. Use higher temperatures for exotic printing materials such as Nylon, Polycarbonate and more!

- Printable Mounts – Maximum compatibility with printers on the market. Currently we have developed and tested mounts for a Prusa Mendel, but we will release the mounting layout for development of all types of mounts, including for mounting accessories (fans, cameras, etc)

- Bowden Compatible – Can easily be adapted to use as a Bowden extruder.

The price for a Kraken starts at $350 and they should be shipped around March 2014. Check out the Indiegogo page for more info.

We must say that the Kraken looks incredible enticing if all what is claimed is true. Time will only tell but so far it looks great.