What are Thread Forming Screws? Use Cases and Advantages

Doing DIY home improvement projects is usually a fun activity, but it can quickly get frustrating if you don’t have the proper tools on hand. With a little extra preparation and knowledge of the tools and parts that you’ll often need, you can save yourself a lot of quick trips to the hardware store.

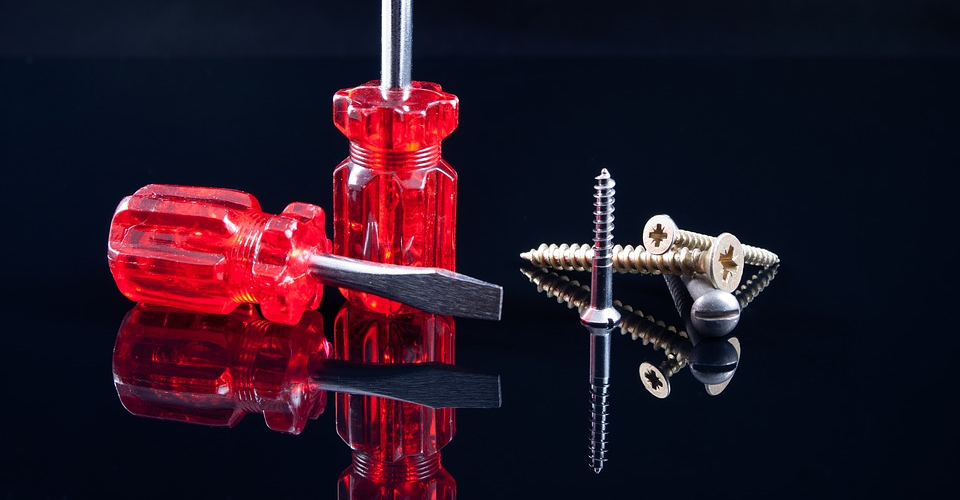

In this article, we take a look at one of the most useful things you can add to your toolbox: thread forming screws. What are thread forming screws and how do they work? What are its advantages and when should you be using one?

Thread forming screws vs. thread cutting screws

Thread forming screws and thread cutting screws are two closely related and similar-looking screws used to attach materials together like plastics, wood, or metal. They are characterized by blunt ends which means they need to have a hole primed in the material before they are inserted.

These two screws are more generally known as tapping screws because of their ability to mate threads into the material they are driven to. As opposed to standard machine screws with the same thread pitch, tapping screws are made with harder metal and a different point geometry that allows them to create their own thread into a primed hole. They are usually case hardened, have very high tensile strength and torsional strength values.

A thread cutting screw creates a thread by cutting into the material. It has a cutting edge and a chip cavity that allows it to remove bits of the material it is being driven into. The cutting motion means that less torque is needed drive in a thread cutting screw and that the material experiences minimal internal stress because it does not get compressed. However, the cutting action also leaves a very small clearance between the screw and the material which may lead to further damage if the assembly vibrates regularly.

In contrast, a thread forming screw does not have any cutting edge and instead merely deforms the material to form a compatible thread. With none of the material removed, this means that the material undergoes internal compressive stress. This could be problematic in specific applications or in materials with low compressive strength values. However, the advantage of a thread forming screw is that it creates a very tight fit between the screw and the material.

Both types of tapping screws are easily available in differential metal types and grades, with each one tailored for use with a specific substrate material. You can also get them in either a coarse or fine thread pitch. Coarse threads are generally used for weaker materials since they cut away less material or generate less internal stresses. Fine threads are recommended for use with thin substrates which may not have enough thickness to accommodate more than one full thread of a coarse-threaded screw.

Pros and cons of using thread forming screws

Despite the unique capabilities of thread forming screws,

PROS

1. Rapid insertion

Tapping screws are used to drive screws into materials where there isn’t a threaded hole ready yet. With a tapping screw, there’s no need to spend more time to tap a thread into this hole. This can save you a lot of time and requires fewer tools. If you just want to finish the job quickly, then having a few pieces of thread forming screw would be very handy.

2. No fasteners or adhesives needed

With a typical machine screw that has been inserted into a pre-threaded hole, a fastener in the form of a locking washer or nut is often needed to hold the screw in place. If a nut cannot be used for some reason, then a bit of adhesive is applied instead. Either way, a fastener or adhesive holds the screw in place so that it cannot be removed easily by vibrations or by constant movement.

The self-locking mechanism of a thread forming screw means that this measure is no longer necessary. Thread forming screws, by their very principle, produce a very tight fit that will take a lot of effort to loosen.

3. Can be used when access is only possible from one side

When fastening a screw in place, access to both sides of the material is needed to insert a compatible nut or to apply some adhesive. This isn’t possible in all scenarios, particularly if you’re inserting a screw into a wall. A thread forming screw eliminates this requirement and provides a secure connection even when you only have access to one side of the material.

4. Zero-clearance insertion

A zero-clearance intersection distinguishes between thread forming screws and thread cutting screws. Since thread forming screws create threads simply by ‘pushing’ into the material, it necessarily forms a very tight fit between the material and the screw. This zero-clearance fit is perfect for parts that experience a lot of vibration, such as in industrial equipment.

CONS

1. Requires a huge amount of torque

Compared to a thread cutting screw that removes resistance of the material by cutting away on it, a thread forming screw is subject to tremendous resistance as it deforms the material to form a thread. This resistance can be greater for very hard materials such as concrete or specific metals. Make sure you have a powerful drill on hand if you’re set on using a thread forming screw.

2. Creates internal stresses on the material

When a thread forming screw deforms the material to create a thread, the compressive forces creates an internal stress in the material in all directions emanating from the threaded hole. If you have multiple holes on a single material, these compressive forces may accumulate or cancel out depending on where the holes are located. This internal stress is something that you’ll need to manage, especially if you’re working with a material that has a low yield strength. If left unchecked, using too many thread forming screws may result in the material breaking apart.

Best uses of thread forming screws

1. Mounting objects on walls

The most common use of thread forming screws can be observed when anything has to be mounted on the wall. Since a wall can only be accessed on one side (unless you’re drilling through), the self-locking mechanism of thread forming screws can be especially handy. Even without the use of fasteners, thread forming screws can provide strong and secure mounting for heavy objects. The effects of internal stress are often negligible in walls because they get distributer over a very large area.

2. Industrial equipment

When they are first assembled, the components of industrial equipment such as pumps, motors, and conveyors are often connected using thread forming screws. The zero-clearance connection of thread forming screws are preferred for these applications as they reduce the deleterious effect of the constant vibration that these pieces of equipment endure during operations. Although the threads will still eventually get worn down and have to be machined, the zero-clearance fit is valuable in delaying the inevitable.

3. Medical or dental implants

One of the more unusual uses of thread forming screws is in surgical techniques to reconstruct fractured jaws and portions of bone. The titanium screws used for such applications are often either thread forming or thread cutting so that they can be as secure as possible and not produce vibrations when already put in place. In most cases, these screws have to be fastened securely enough for lifelong use. Surgeons also have very limited space to work with when installing these screws, which is why they prefer the simplicity of not having to thread holes in preparation for insertion of a screw.

These applications form just a small selection of the uses of thread forming screws. They are pretty much everywhere even if you don’t realize their presence. They are used in metal brackets and wood panels for house furniture, metal panels in automobiles, and plastic sheets used in laboratory equipment.

Final thoughts

Thread forming screws are an incredibly useful tool and something that you should always have on hand if you like doing quick repairs around the house. They are very reliable and easy to install given that you have the right power tools. There’s really nothing complicated in how they work, but it is this simplicity that makes them such an appealing option for mounting or connecting pieces together. If what you want you is a very reliable and strong connection for any type of material, then a thread forming screw should definitely be one of the top options.