Tips for 3D Printing with ABS Plastic

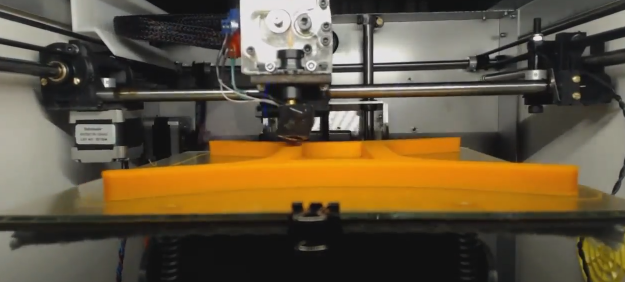

Printing with ABS plastic can be a frustrating experience. Many a time our prints have come out warped and sometimes they even find themselves being thrown around the print bed after they’ve come unstuck. So what can you do if your ABS prints are having trouble printing? We’ve compiled a quick list of mods and additions you can make to your 3D printer to improve ABS printing performance.

Printer Calibration

Calibrating and setting up your printer should really be the first thing you do when you get it out of the box. Make sure the print bed is level and if you are having trouble with prints warping at the bottom or coming off the print bed you could check the first layer height or Z-offset/height. To make the first layer stick better, the Z-offset can be set so the extruded plastic gets slightly squished when it hits the print bed.

Additionally, Print bed temperature should be set high (around 100 degrees Celsius) and make sure the your printing is extruding the correct amount of plastic. Another tip is to set the first layer speed to around 30-40% of the print speed. This will improve adhesion to the print bed and will hopefully reduce the risk of warping and lift off.

Adhesive Surfaces

When it comes to warping and lift-off, the first thing people recommend is to apply a substance/spray that will improve adhesion. There are a number of products that we’ve seen used and we’ll go over a few of them in this post. Additionally, we recommend you get some glass plates cut (around 2mm thick by the area of your printer’s build platform), so you can quickly and easily apply different adhesive mixes.

Hairspray is a common product used to improve adhesion on print beds. Just spray it on evenly and wait for it to dry. We found that hairspray works for the majority of prints; however there are other options that provide better adhesion.

Another way to improve adhesion is mixing acetone with a bit of ABS plastic to make an ‘ABS, acetone slurry’. To make the slurry simple take some scrap ABS, either from a failed or unwanted print and then put it in some acetone until it melts. Usually it takes around three tablespoons of acetone to around two square inches of ABS and the final results should come out to be of a similar consistency as light paint. This option seems to offer the best adhesion, although we’ve found that prints often stick too well and can be a nightmare to get off the print bed/glass plate. The video below explains how to make an ABS, acetone glue mix that can be used for adding adhesion to the print bed, or it can be used to glue parts together.

The method we personally use is mixing PVA glue (carpenters/wood glue) with a bit of water. This seems to offer great adhesion while being cheap and it doesn’t release any nasty fumes like acetone does. There’s no real science to this method and if you need more adhesion increase the percentage of PVA, while decreasing the percentage of PVA will lower the amount of adhesion. Another benefit of this method comes when you want to get a print off. Simply put the whole print bed or glass plate (if you’re using one) in water and come back in ten minutes. The water should dissolve the PVA and your print should snap off easily.

There are a few off the shelf adhesive products that are designed specifically like Cubify’s Cubestick; however we feel these products are often overpriced and you’re better off with the methods above.

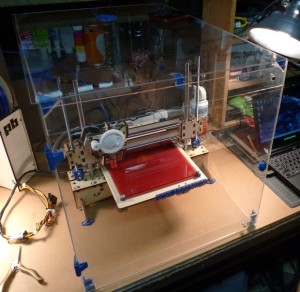

Enclosure

If you’re still having trouble with lift-off and warping issues with ABS plastic another good tip is to build an enclosure around your printer. Quite a few new 3D printers are coming with enclosures or build chambers; however many printers don’t and almost all can benefit from them.

Building an enclosure doesn’t have to be complicated and sometimes you’ll find pre-made enclosure designs for your printer on websites like Thingiverse. Designing an enclosure really comes down to your needs and many people like add things like filtration systems and built in filament spools.

For those looking for a quick fix, material’s like foam board or even cardboard can be used to construct an enclosure quickly and easily. More temporary solutions can be built from materials like Perspex or laser cut wood. Another option is to buy a cheap cupboard or shelving unit from a furniture store and stick your printer in there.

Filament Care

Correctly storing your ABS filament can drastically improve print quality, while reducing the likelihood of warping and lift off. Make sure filament is stored in an air tight container or bag (those food storage containers work pretty well), and if your filament does become saturated with water you can dry it off in the oven for a while. ABS plastic does not become as saturated as PLA plastic filament; however it is still important you correctly store ABS plastic filament.

Finishing

Desktop FDM 3D printers can’t print perfect objects, in fact almost all 3D printers; even the commercial ones have trouble printing smooth objects. If you are using ABS plastic there is a way to quickly and easily improve the quality of a print.

Many printing enthusiasts use an acetone bath or acetone vapour treatment to drastically improve the finish of an ABS print. Submerging or painting a model with acetone does smooth out some of the defects and lines in a print; however small details can be completely removed by this method.

If you have the time, we recommend you build an acetone vapour chamber, which provides the best results overall. YouTube user ‘Maker’s Muse’ has a cool video explaining the acetone vapour process which can be viewed below.

Wrap Up

So in conclusion, there are a number of options to improve your experience with ABS plastic. The first step is to calibrate the printer, then prepare the print surface with a solution like an ABS, acetone mixture. If you are still having issues, an enclosure can really improve warping issues by keeping the air around the print bed at a constant temperature. It also has other benefits like reducing the noise of the printer and filtration systems can be added to reduce the amount of nasty fumes released into the surrounding environment. Finally, correctly storing filament can greatly reduce the risk of defects in your prints and warping issues.