University Of Nottingham 3D Prints Robotic Arm

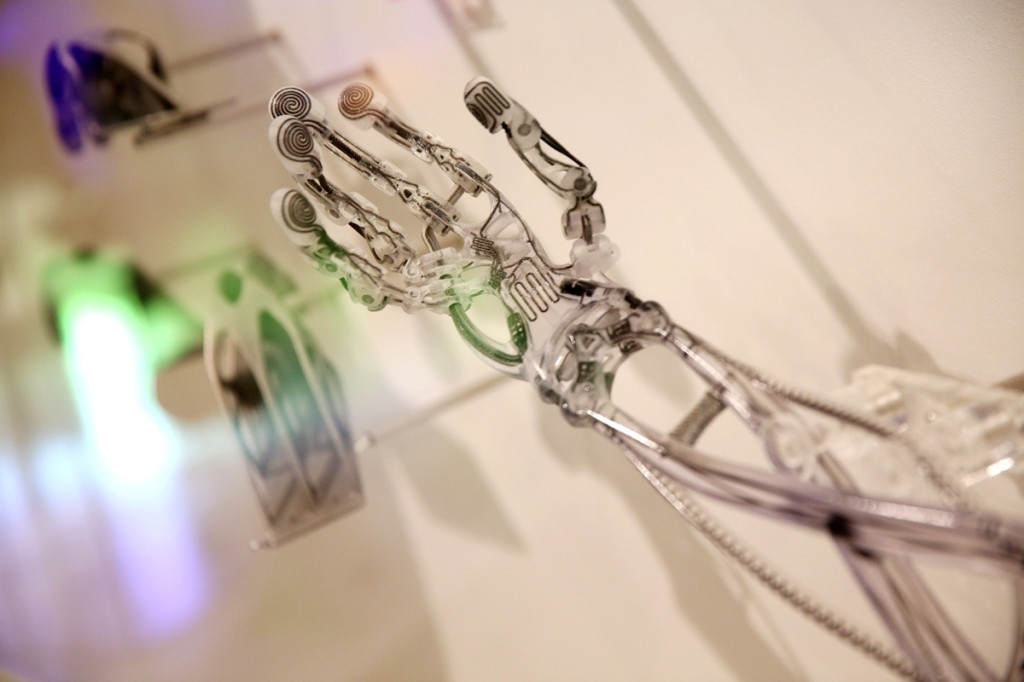

The London Science Museum’s 3D printing exhibition holds host to 600 3D printed objects from around the world. Every piece at the exhibition has its own unique story, but one of the more interesting items is a transparent robotic 3D printed prosthetic that gives an insight into what the future may hold. The arm itself is just a mock-up of what could be possible in the future and features circuitry, along with temperature sensors.

Created by researchers at the University of Nottingham, the robotic arm demonstrates the usefulness of 3D printing and its potential to transform the was we make and buy things. “At the moment 3D printing uses single materials, a polymer or a metal, which are fused together with a laser,” said Professor Richard Hague, Professor of Innovative Manufacturing and leader of 3D Printing Research Group. “You can create interwoven geometries but they’re still passive. What we’re looking to do is activate those and make them functionalise. So rather than make a component you make the whole system — an example might be rather than print a case for a mobile phone you make the whole phone — all the electronics, the case, the structural aspects, all in one print.”

He believes that multi-material 3D printers will need a tremendous amount of work before they are ready, but those systems may only be 10-15 years away.

The university’s arm is similar in nature to prosthetic projects such as this one that revolves around the 3D printed Inmoov humanoid robot. It is also a step up from Robohand, a 3D printed prosthetic hand that has been changing peoples lives around the world.

Hague believes that an exciting new world awaits 3D printing and the future development of metal 3D printing could drastically alter manufacturing in the future. Him and his team are currently developing their own metal 3D printing technique and further develop others, “That will be globally unique — nobody else will be working on that. We are working with an industrial partner to develop a system that jets metal. At the moment you can only jet nano flakes of metal in a polymer ink.” He said.