Welding, Brazing, and Soldering: Definitions, Differences, and Applications

The manufacturing industry may be in a constant state of evolution, but that does not mean that more traditional techniques will ever go out of fashion. The ability to join metals is a very critical part of a lot of industries, such as automobiles, construction, and industrial equipment. When it comes to this field, the techniques of welding, brazing, and soldering continue to be the most commonly used, despite being old techniques.

What are the differences between welding, brazing, and soldering, and how do they work? When should you be using one technique over the others?

How are these techniques similar?

There’s a perfectly good reason for why these three techniques, in particular, are being lumped together and compared: they are all used to join pieces of metal. The types of metal you are working with, the objectives of the process and the type of equipment you have will determine which technique is best.

All three techniques involve melting of a metal, whether it’s a filler metal or the actual pieces of metal you are joining together. This means that intense heat plays a central role in all three processes. It is also important that the pieces of metal you are working with are perfectly clean before you start. Failing to clean your metal parts can lead to poor quality joints or welds, no matter which technique will be using.

Lastly, executing any of these techniques requires that you wear a full complement of protective equipment. At a minimum, you should be wearing gloves that will protect you from extreme heat or small metal fragments. Depending on the technique, you might also need some form of eye protection.

WELDING

Welding is a technique used to join together two pieces of the same metal. It is distinct from brazing and soldering in that the process melts the metal itself to form a very strong weld or joint. By melting the metals and joining them together, they fuse at the molecular level after cooling.

Most welding applications also involve a filler metal that forms a molten pool and enhances the strength of the joint. Welded joints are typically as strong as or slightly stronger than the base metal.

Welding is a highly versatile technique. The heat requirement to melt the base metal can be supplied in several ways: an electric arc, a laser, friction, ultrasounds, or a simple gas flame. The quality and strength of the weld can also be improved by applying pressure on top of the heat. Because of the variety of ways that heat can be applied for successful welding, it can be modified for use in different environments. Welding has been done in the open air, underwater, and even in outer space.

Applications and Examples

Due to the superior bonding strength produced by welding, it is one of the more important processes in several industries. For standard repair work, fabrication of pressure vessels, and in the shipbuilding industry, the preferred method is shielded metal arc welding (SMAW). This technique uses a flux-coated electrode to conduct a current to the metals being welded. In addition to melting the metals, the flux at the electrode also vaporizes to form a gas that prevents contamination of the weld. The electrode material consequently also melts and act as the filler metal.

The gas tungsten arc welding (GTAW) technique, more commonly known as tungsten inert gas (TIG) welding, is considerably more complex and requires more skill in the part of the welder. Instead of a consumable electrode, this technique uses an electrode that remains solid and does not become a part of the weld. Instead, the filler metal is supplied via a thin wire of filler that the welder feeds into the weld pool. The clean, precise welds produced by GTAW are highly valuds in the airplanes, racecars, and other types of vehicles. GTAW is also typically used for pipes used in the chemical and petroleum industries.

In the manufacturing of common consumer goods such as home appliances, the technique of gas metal arc welding (GMAW) is typically used. More commonly known as metal inert gas (MIG) welding, this was the first technique to use an inert shielding gas, such as argon, to prevent contamination to the weld. In this process, a solid electrode wire is fed to the base metal through a gun, melting both the base metal and the electrode which acts as the filler metal. At the same time, the feeding mechanism releases the shielding gas through a separate cartridge. The biggest advantage of this technique is that it can be semi-automated and can be done quickly, making it the preferred technique for high volume production.

There are other welding techniques, such as submerged arc welding, gas welding, and ultrasonic welding, among others. However, these are much less commonly used as the three that we have mentioned above.

Advantages

The primary reason for why manufacturers turn to welding is the relative strength of welded joints. These joints are typically at least as strong as the base metal. With the right technique, they can even be stronger. This has made welding the ideal technique for weight-bearing products or equipment that may undergo extreme levels of stress.

The other great advantage of welding is that it has become such a well-developed technique over the last few decades that there are now lots of different ways to execute a welding job even in challenging conditions. This has opened the possibility of repairing ships even when the damaged sections are underwater, or for construction of gas pipelines in high-altitude areas such as the Andes.

Limitations

Since welding works by melting the base metals and fusing them together at a temperature just above melting, the technique requires that the two pieces of metal have similar melting temperatures. To simplify this matter, welding has been used exclusively for joining together pieces of the same metal. If you have different metals, you will need to turn to a different technique, as we shall see later.

Of the three techniques discussed here, welding is considered to be the most hazardous. Welding requires extremely high temperatures – up to 3800 °C. This requires a much higher degree of heat protection on the part of the welder. Heat and energy also cost money, making welding one of the more expensive options.

Although large manufacturers can now afford to install semi-automated welding equipment, most of the welding jobs done globally are still being performed manually. Pulling off a welding job that looks good and has superior strength requires a very high level of skill. There are lots of things that could go wrong during welding operations, which can result in warping of the base metal, welded joints with a porous appearance, or welded joints with low strength. Indeed, skilled welders are highly valued in a lot of industries.

Speaking of aesthetics, welding produces a highly visible weld joint, even in the hands of a skilled welder. While this joint can be ground, polished, and painted over, this requires additional work on the part of the manufacturer to make their products more visually appealing. Smooth joints are also highly valued in gas and steam pipelines, where localized contamination due to porous joints are highly likely.

BRAZING

Brazing is a technique for joining pieces of different metals. Instead of melting the base metals, brazing is instead done by melting a filler metal. This filler should melt at a temperature that is significantly lower than the melting temperature of the base metals.

Applications and examples

In a brazing operation, heat is not applied directly to the filler metal. Instead, the base metals are heated to a temperature a little above the melting temperature of the filler metal. The base metals then come into contact with the filter metal, melting the filler metal instantly. The molten filler metal travels through the joint by capillary action, filling it uniformly and creating metallurgical bonds with the surfaces of the base metals.

There are several techniques for the application of heat to base metals before brazing. Most automated processes us furnaces to pre-heat metal parts that have been pre-loaded with the filler metal. It’s also possible to apply heat directly to the base metal using an acetylene or propane torch. If there are parts of the metal that are sensitive to heat, localized heating can be done via an induction coil that passes an electrical current to the part of the base metal that has been preloaded with the filler metal.

Brazing is used in practically all industries where welding is also applied. It holds a unique position, though, because of its ability to bind two different metals. From large-scale jet turbine blades and satellite components to small applications such as electronics and jewelry, brazing is considered nearly as valuable a manufacturing technique as welding.

Advantages

Brazing fills in the gaps of industry needs that welding cannot solve and is the most popular method of joining dissimilar metals across virtually all industries. The temperature needed to melt a filler metal for brazing is much lower than the temperatures for welding – within the range of 620 °C to 870 °C. Not only does this make brazing an inherently less hazardous technique, but it also requires fewer expenses due to heat and energy.

Brazing does not require as much skill as welding. While quality welding is based on a synchronized application of heat and welding material, the biggest challenge of brazing lies in the design and engineering of the joint. Developing this skill takes much less time, and there are significantly fewer things that could go wrong during brazing. Since the base metals themselves are not melted, they don’t run a risk of compromising their physical properties.

Because of the relative simplicity of brazing, it can be more easily automated and integrated into existing manufacturing processes. Most consumer goods are manufactured using some form of automated brazing.

A good brazing job results in a very clean product. In contrast to the visible joint produced by welding, brazing produces two metals bound by a thin and even fillet of filler metal. This characteristic is valuable in the production of consumer goods where appearances are critical. A brazed joint typically looks good enough without any post-processing, saving on additional costs and time for the manufacturer.

Limitations

Despite the numerous advantages of brazing, there’s still a very good reason why welding is the more preferred technique for joining similar metals: a welded joint is still stronger than a brazed joint. Brazed joints also cannot be used to manufacture parts that are meant to be exposed to high temperature or pressure, such as certain satellite, aircraft, or automobile components.

SOLDERING

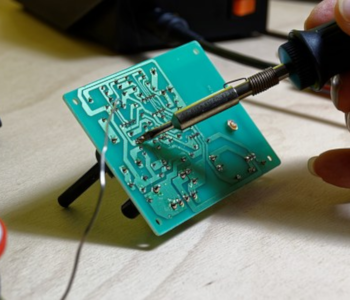

Soldering is the simplest of the three techniques and is something that can be done for household electronic repairs. It is more closely related to brazing than to welding in that it relies on the melting of a filler metal to join together two different metal components.

However, the objective of soldering isn’t to form a strong bond between two metals. Rather, most soldering applications only aim to provide an electrical connection between two different electrical components. The soldered joint isn’t necessarily strong and has a much lower fatigue resistance compared to a brazed joint. Soldering utilizes a much lower temperature – 450 °C or less.

Applications

Although the most popular application soldering is in electronics, it is also widely used to manufacture pipes and vents for heating and air-conditioning. Soldering is particularly suited to fine and detailed work on small components, making it an excellent technique for jewelry and stained glass work. Moreover, since it works at a fairly low temperature, it is the preferred technique for binding of sheet metals and pipes made of soft metals such as copper and aluminum.

The manufacturing industry as a whole has mostly moved to the use of lead-free solder material. Modern building codes, in particular, require the use of lead-free solder for piping meant to deliver potable water.

For batch processing of printed circuit boards (PCBs), an automated process using either wave soldering or reflow soldering is typically used. In wave soldering, PCBs on a conveyor pass over a pan of molten solder which then upwells through orifices in the PCBs. Components to be soldered to these PCBs are glued in place before they pass over the pan of molten solder. The upwelling of the molten solder produces a standing wave which solidifies upon cooling and binds the components to the PCB.

In contrast, the reflow soldering workflow is more of a batch process, rather than continuous. In reflow soldering, a solder paste made of powdered solder and flux material is used to attach the electrical components to a PCB. A whole batch of these PCBs is then exposed to a controlled heat source, which melts the solder paste. The solder material then solidifies upon cooling and permanently binds the components to the PCB.s

Advantages

Of the three techniques discussed here, soldering is by far the simplest and easiest to do. Since soldering requires much less sophisticated equipment, a person with minimal training can do soldering even at home. Automated soldering technology is already very common, particularly in the manufacture of PCBs. As with brazing, soldering can be used to join together dissimilar metals.

The low-temperature characteristic of soldering has also made it suitable for working with metal sheets and other thin metals. Because the base metals are not subjected to a high level of thermal stress, they are less prone to warping or alteration of their physical properties. Soldering is one of the least energy-intensive techniques for joining metals, making it extremely cost-effective.

Hand soldering is still a common practice, particularly in applications where fine, detailed work is needed. There is a huge variety of soldering irons designed for hand soldering, from 25-watt irons meant for printed circuit boards to 100-watt irons designed for large electrical connectors. Although hand soldering takes a considerable amount of skill, it is not as notoriously difficult to master as welding or brazing.

Limitations

Soldering is a technique that simply cannot be counted on if you need any sort of strength in your joint. Solder metals are soft and melt at low temperatures, which also means only components that cannot be exposed to extreme heat should be bound via soldering.

Other methods of joining metals

The three techniques discussed here are by no means the only techniques used to join metals together. There are, of course, mechanical means such as threading or screwing. These methods have the benefit of being non-permanent, although they require skilled machining. For more permanent bonds, there is also the option of using metal to metal adhesives. Using adhesives requires very little skill, but the binding strength of such a technique is comparable to what you would get from soldering.

Final thoughts

Some manufacturing methods used nowadays, but other traditional methods will always stay in fashion. The techniques of welding, brazing, and soldering may be a few decades old, but they are still some of the most reliable even today. Each one requires a considerable amount of skill, but technology has evolved enough to allow for the automation of any of these techniques.

The main factor that differentiates between welding, brazing, and soldering is temperature. The amount of heat needed to execute these techniques plays a key role in determining how strong the resulting joint is, how much it can withstand extreme conditions, and what it looks like. It also determines how expensive the process is, as well as how skilled an operator needs to be to produce good results.