What is a Delta 3D Printer? Pros, Cons, and Best Brands

3D printers are common enough nowadays that just about everyone has probably seen one in action at some point. Particularly popular are FDM printers, or those that print using plastic filament. However, not many may know that there are still several types of FDM printers, with each one having a set of advantages and drawbacks.

In this article, we turn the spotlight to Delta 3D printers. They are easy to identify with their triangular form factor. What is a Delta 3D printer, and how does it work? How does it compare to the “standard” 3D printer?

What is a Delta 3D printer, and how does it work?

Before diving into what a Delta 3D printer, let’s define what the “usual” 3D printer is so that we have a point of comparison. A large majority of the desktop 3D printers that you can see nowadays are what we call “Cartesian” 3D printers. This is so-called because the print head moves according to the Cartesian coordinate system – that is, the x, y, and z directions. A set of three unique numbers are assigned to every single point in a 3D model, which corresponds to its location in 3D space defined by Cartesian coordinates.

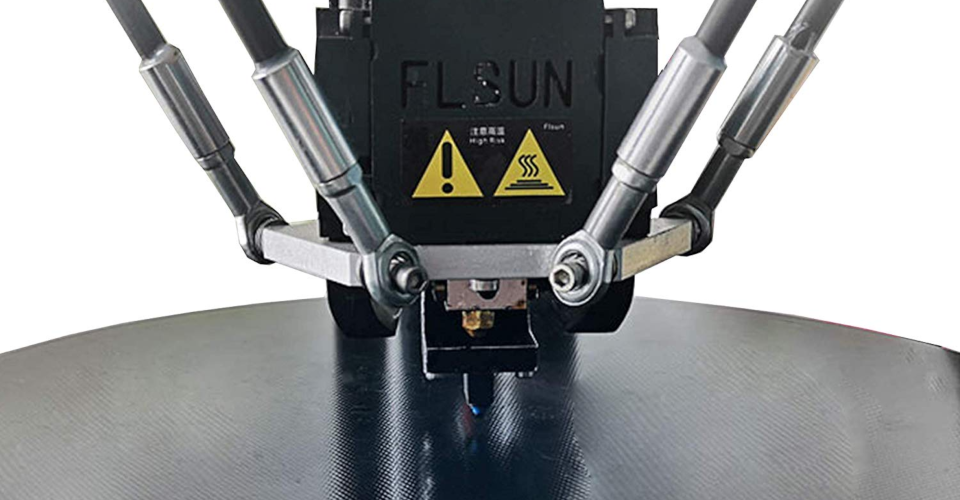

A Delta 3D printer takes a different approach to locate points in 3D space. Instead of a print head that moves along the forward-backward, left-right, and up-down axes, the print head is instead mounted on three moving arms. These three arms independently push and pull on the print head to control its position.

There is a sort of “gray area” when it comes to distinguishing between Cartesian and Delta 3D printers. This is because Delta 3D printers still plot points along the Cartesian coordinate system. However, the coordinates have to be translated to the specific angles that each of the three articulating arms need to be at. This translation is done via simple trigonometric functions.

The three arms of a Delta 3D printer give it its distinct triangular frame, so identifying one is pretty easy. It typically has a stationary circular print bed. Delta 3D printers are thin and long, making them suitable for printing tall and narrow models. Cartesian and Delta 3D printers essentially use the same types of filaments, with special consideration going towards flexible filaments.

Aside from the two movement types of FDM printers that we have mentioned here, there are two others that are much less common. The first is the polar 3D printer, which has a print bed that moves and rotates relative to a stationary print head. The rarest type of FDM printers is the Selective Compliance Assembly Robotic Arm (SCARA) printer, a highly precise and incredibly compact 3D printer that looks like it came straight out of a science fiction movie.

Pros and cons of Delta 3D printers

On the surface, a Delta 3D printer seems like a very good alternative to the usual Cartesian 3D printer. In some way, this is true. It’s not perfect, though. If you’re considering getting a Delta 3D printer, then here are the pros and cons to consider:

PROS

1. Fast

Delta 3D printers were built for speed. Each of the articulating arms is powered by a separate stepper motor, allowing them to move the print head very quickly. The print head itself is built to be very small and light. All Delta 3D printers use a Bowden extruder which moves a lot of the moving parts away from the print head.

By keeping the print head light and having it supported by three arms, Delta 3D printers eliminate the major speed limitation of Cartesian 3D printers. In a Cartesian 3D printer, the large of the weight of the print head generates a lot of momentum as it moves, making it prone to “overshooting” from its intended position. Any slight error will accumulate as the project proceeds, resulting in an almost unusable print.

Print speeds of up to 300 mm/s are not unheard of when using Delta 3D printers. Cartesian 3D printers typically print at about a fifth of that speed. If you are running a 3D printing business where quick turnover is valuable, then a Delta 3D printer would definitely be the better choice.

2. Suitable for tall models

Due to the way that Delta 3D printers work, their build platform is limited to the area that lies between the three articulating arms. This is a very small area, so the manufacturers of Delta 3D printers compensated by adding quite a lot of height. The arms of a Delta 3D printer can move up and down along its columnar body, allowing for the printing of very tall models. Ornate columns and architectural models of towers are especially suited to Delta 3D printers.

CONS

1. Limited base size

Related to the item above is the fact that Delta 3D printers have a very small circular base compared to Cartesian 3D printers. If you’re working exclusively with a Delta 3D printer, it may be necessary to split models into separate parts. Obviously, this adds a bit of work and introduces more steps to the process where things can go wrong. If you have no plans of building particularly tall and narrow models, then a Delta 3D printer may not be a wise investment.

2. May not work well with flexible filaments

Delta 3D printers exclusively use Bowden extruders, both because it optimizes the rapid movement of its three arms and because a Direct extruder simply won’t fit inside the print’s narrow space. While the use of a Bowden extruder helps a Delta 3D printer operate rapidly, it also introduces complications if you have to use a flexible filament like TPU or TPE.

As anyone who has ever used flexible filaments before, they are highly prone to deforming inside the extruder assembly. The design of Bowder extruder extends the path of the filament between the extruding gears and the nozzle. This extra room increases the chances of deformation of the filament, especially if you haven’t keyed in the perfect printing parameters. A deformed filament can lead to extrusion problems, or worse, clogging of the nozzle.

This does not make printing with flexible filaments impossible with a Delta 3D printer. It only means that there’s going to be a bit more work involved, and you’ll have to anticipating things going wrong more often.

3. Difficult to use and troubleshoot

The major advantage of Cartesian 3D printers becoming so popular is that they are now more user-friendly than ever. Not only can they be purchased fully assembled, but there are also thousands of online communities, help pages, and video tutorials that can help you develop your skill or troubleshoot any problems. In many ways, a Cartesian 3D printer is perfect for a beginner.

The same cannot be said for Delta 3D printers. These printers typically come in separate components that need to be assembled. With more motors and moving parts, there’s also a lot more that could go wrong with a Delta 3D printer. This is doubly difficult as there aren’t a lot of users of Delta 3D printers, and its communities aren’t quite as thriving. Before you buy a Delta 3D printer, you must already have a deep understanding of the mechanics of 3D printers and be ready to DIY just about everything.

Delta 3D printers can be very useful in certain situations, but they are not going to absolutely replace Cartesian 3D printers. If you’re just starting out, then a Cartesian 3D printer may still be a better option. However, those looking to upgrade both their equipment and their skills would certainly recognize the appeal of a Delta 3D printer.

The top 3 best Delta 3D printers available today

1. Best overall: Monoprice Delta Pro 3D Printer

For the best in desktop Delta 3D printers, it would be a challenge to find a model that’s better than the Monoprice Delta Pro. As its name implies, this is the professional-grade Delta printer from popular 3D printing brand Monoprice. This printer has a huge build area that measures 270 millimeters across and 300 millimeters high. Despite the size, it is delivered fully assembled. It has an all-metal construction with components that fit together perfectly, leaving no room for wobbling or warping during operations.

The Monoprice Delta Pro is a very smart 3D printer. The PID controller keeps the printing temperature very stable, even when the printer is subjected to changing environmental conditions. The extruder temperature can go as high as 310 °C, while the bed can be heated up to 100 °C. High-temperature filaments like PETG, Nylon, and ABS are perfectly suited to the Monoprice Delta Pro.

The Delta Pro can print at resolutions of up to 50 microns and a maximum printing speed of 150 millimeters per second. It comes with an easy-to-use touchscreen interface and can be loaded with 3D models via USB or SD card.

The drawback of the Delta Pro, which is quite common with Delta 3D printers, is that it’s obviously not designed for beginners. It doesn’t come with a lot of documentation, so even setting it up might prove to be frustrating. It’s also quite expensive compared to the other entries in this list, but it also still costs less than $1000. That is not a bad price tag for a Delta 3D printer that claims to have professional-grade quality.

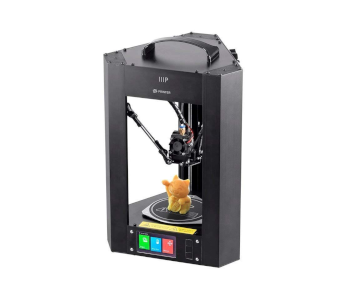

2. Best budget: Monoprice Mini Delta 3D Printer

At less than $200, the Monoprice Mini Delta is an amazing bargain. This is a compact and lightweight 3D printer that even comes with a carrying handle so you can move it around the house. It comes with the usual polished and minimalist design as some of Monoprice’s much pricier models. With black all-metal frames and a pre-built form factor, the Monoprice Mini Delta looks much more professional than most of the other 3D printers in the sub-$200 price range.

Like its more expensive counterparts, the Monoprice Mini can print at resolutions of up to 50 microns. The nozzle can be heated up to 260 °C and the heated bed up to 60 °C. The maximum heated bed temperature is quite problematic, as it may not get hot enough to avoid warping of high-temperature filaments like ABS and Nylon. This is a massive limitation that we cannot overlook. Fortunately, the Monoprice Mini is still a very fast 3D printer that can print at speeds of up to 150 millimeters per second.

As you would expect from such a small 3D printer, the build size of the Monoprice Mini is also limited. The build area measures 100 millimeters across and 120 millimeters high – basically the size of an action figure. This build size is fine if you’re just doing 3D printing for fun, but there aren’t many professional uses for the Monoprice Mini.

The Monoprice Mini has a touchscreen user interface which makes navigation easier. 3D models can be loaded via micro USB, a microSD card, or a WiFi connection. We suggest sticking with the microSD card to ensure that your print does not get interrupted.

3. Best value: FLSUN QQ-S Pre-Assembled Delta 3D Printer

If you can spend a little more than the cost of the Monoprice Mini, then you can get the FLSUN QQ-S Delta 3D Printer which is much more versatile. It’s a better Delta 3D printer almost across the board with a bigger build area and a more extensive temperature range. It also still costs less than $500, so you won’t exactly be spending a fortune.

The FLSUN Delta 3D Printer features an all-metal frame and requires a small amount of assembly upon delivery. A spool holder sits at the top of the 3D printer which also doubles as a handle if you need to carry it around. It’s a little less portable than the other entries on this list. However, this isn’t an issue if you have no need to move the printer regularly.

The build area of the printer measures 255 millimeters across and 300 millimeters high, which is almost as big as the Monoprice Delta Pro. It can print features as small as 50 microns and has a maximum printing speed of 300 millimeters per second. Its nozzle temperature goes as high as 270 °C, which should be hot enough for printing with ABS or Nylon. This is perfectly complemented by a bed that can be heated up to 100 °C. Although this still falls short of the recommended bed temperature for some high-temperature filaments, it’s certainly much more manageable with the help of some adhesives.

You’ll need to have some amount of mechanical knowledge to set up the FLSUN QQ-S, but it’s an incredibly reliable piece of machinery once it gets going. For its price, it provides incredible value.

Final thoughts

A Delta 3D printer is just one of several movement types developed for FDM printers. It may not have the far-reaching popularity and versatility of Cartesian 3D printers, but it definitely serves a purpose. They may have limited build size, but they make up for it with pure speed.

3D printing professionals know how valuable printing speed can be, especially if you need to create several prints, and you don’t have a lot of time. The good thing about Delta 3D printers is that they achieve very high printing speeds without compromising on quality. If you want good-looking 3D prints made quickly, then you should consider getting a Delta 3D printer.