What is Centrifugal Casting? Applications, Pros, and Cons

With our abundance of materials and technologies, there are now seemingly endless ways in which they can be utilized to support a growing global economy. At the very core of any economy (aside from the people) are the large-scale industries that deliver goods and services such as energy, utilities, and various consumer products. The processes in these industries have to be highly reliable despite very harsh conditions.

For such industries to perform at such a high level, the infrastructure that supports them must be similarly reliable. The process of centrifugal casting was made for this purpose. What is centrifugal casting and how does it work? What is it used for?

What is centrifugal casting?

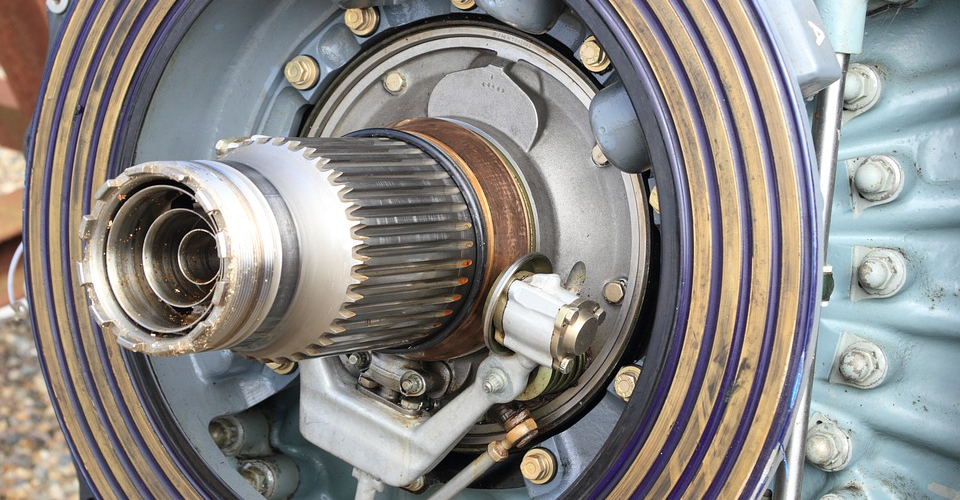

Centrifugal casting, also known as roto casting, is a manufacturing process for rotationally symmetric parts such as pipes and equipment casings. The process is called as such because it uses centrifugal forces generated by a rapidly rotating cast to push the molten material against the inner surface of the mold. The result is a remarkably even distribution of the metal and a grain distribution that enhances the part strength.

Any material that can take on fluid properties when heated can be used for centrifugal casting. Typical materials used are iron, glass, stainless steel, and various alloys of aluminum and copper. The molds used in centrifugal casting can be made from steel, cast iron, or graphite.

How does centrifugal casting work?

To start off, molten material is poured via a funnel system to the permanent mold, which has been pre-heated to the appropriate temperature. At this point, the mold is already rotating at very fast speeds – somewhere in the range of 300 to 3000 rpm. As the molten material enters the mold, the centrifugal forces caused by the rapid rotation pushes the material onto the inner surface of the mold.

The mold used in centrifugal casting can be oriented at either the vertical or horizontal directions Verticals molds suitable for parts that are meant to have details on the outer diameter, such as ribs or flanges.

On the other hands, horizontal molds are more often used for long, cylindrical parts like straight tube sections. It is also possible to create several shorter rings or flanges using one long, horizontal mold. Horizontal molds need to rotate at faster speeds to counteract the event of gravity on the molten material.

As the material enters the mold, a cover at the end opposite of the entry point keeps the molten material inside the mold. By controlling the mass of material entering the mold, the thickness of the produced part can be controlled. Thus, it’s possible to use just a single mold to produce parts with different thickness values.

As the mold continues to rotate, the molten material starts to separate according to variations in density. Centrifugal force will force the heavier components of the material closer to the mold, while lighter impurities will tend to “float” out.

Cooling and solidification of the material happen under pressure and proceeds from the outside inwards. Directional cooling helps establish the metallurgical properties of the part (if metals are being used), which helps to make it even stronger. Moreover, cooling of the part while rotation is still continuing avoids shrinkage in the outer diameter and helps manufacturers maintain dimensional accuracy.

It is also possible to create bimetallic products through centrifugal casting by introducing a second material once the first layer has solidified.

A possible alternation to the method is to introduce a vacuum to the inner chamber of the mold. This arrests the corrosive effect of oxygen under high-temperature conditions, further strengthening the part as it cools.

Once the part inside the mold has fully cooled, it is removed from the mold for further machining. The inner diameter of a newly casted mark is typically very rough and uneven because of the presence of impurities and the effect of thermal shrinkage. These imperfections are machined out to achieve the desired thickness and a smooth finish. In some cases, the outermost layer of the finished part is also machined to remove any signs of roughness.

Pros and cons of centrifugal casting

PROS

1. Versatile

As mentioned, it’s possible to use just a single mold to create pipes and parts of various thickness values in centrifugal casting. Through simple changes in the amount of material poured into the mold, different types of parts can be made without a need for tooling changes or process downtime. Time is money, and centrifugal casting is simply cost-effective.

2. Better grain distribution and metallurgical properties

The phenomenon of density layering by centrifugal force and cooling under pressure gives parts created by centrifugal casting a superior level of strength and reliability. Centrifugal casting is also exceptionally suitable for creating thin-walled pipes because of its ability to create perfectly even layers with homogenous composition.

3. Easy separation of impurities

Even with the best refining methods, the raw materials used in machining of parts will naturally have impurities that have negative effects on their mechanical properties. Centrifugal casting is one of the few manufacturing methods that effectively removes these impurities. By eliminating these impurities, parts made in centrifugal casting have better physical integrity than those made by investment casting.

4. Good dimensional accuracy

In centrifugal casting, the cooling process of the molten material starts the moment it touches the mold. This continues from the outside inwards, all while the material is under pressure by the rotational forces of the mold. By applying a constant pressure on the material, manufacturers can ensure that parts have consistent outer diameters. The inner diameter, on the other hand, can easily be machined according to desired specifications (and to remove impurities).

CONS

1. Can only be used to cast specific geometries

Despite all the merits of centrifugal casting in terms of speed, reliability, and quality of results, the fact remains that the process is simply not suitable for all types of geometries. By the very principle of its operations, centrifugal casting is appropriate only for parts that are symmetrical across a rotational axis – basically cylinders and its derivatives. For more complex parts, manufacturers have to turn to other methods such as vacuum casting, investment casting, or machining.

Applications of centrifugal casting

Centrifugal casting is a go-to method for applications that require a high level of reliability. Whether due to issues on safety or security, these are the types of industries that have virtually no room for error.

- Aircraft manufacturing – propeller hubs, compressors, cast rings, flanges, shaft sleeves and liners, aircraft loading systems

- Automobiles – cylindrical liners, piston rings, transmission systems, bearing bushes, gear blank

- Petroleum processing plants – Pump and valve housings, furnace tubes, ethylene coils, tube trees, elbows and fittings, high-pressure fluid pipes

- Power plants – steam turbine bearing shells, turbine heat exchangers,

- Electronics – switchgear components

Final thoughts

In centrifugal casting, the centrifugal forces created by the high-speed rotation of a permanent mold results in a finished part that is very strong, free of impurities, and has a consistent composition and thickness. Although the process is severely limited in terms of geometry, it’s almost unbeatable in its reliability. Centrifugal casting is the manufacturing method of choice when companies are looking for parts that absolutely cannot fail.