What is Laser Engraving Leather? Benefits and Applications

Leather has always been considered a value material, both for its appearance and how well it stands the test of time. Items made with genuine leather, from wallets to shoes, are among some of the most expensive and luxurious of their kind. It’s no surprise, then, that the ability to work with leather has remained similarly valuable through the years.

However, a new era of working with leather may already have started with the use of laser engraving technology. What exactly is laser engraving and how does it improve on the artisanal craft of old-fashioned leather engraving?

What is laser engraving of leather?

Laser engraving of leather simply refers to the use of a CO2 laser to engrave custom designs on any type of leather material. By varying the intensity of the laser and the time of exposure, a laser engraving project can be customized to simply etch a design onto the surface of the leather or to cut right through it.

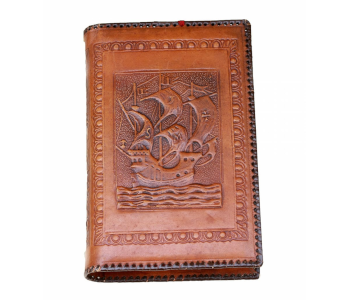

With this in mind, it’s easy to imagine a couple dozen ways to put laser engraving technology to good use for leather products. Common laser-engraved leather products include wallets, notebook covers, leather patches, belts, and elaborate fashion pieces.

Benefits of laser engraving leather

Working with leather using traditional methods has always been a highly valued and respected craft, so what’s the point in making the shift to laser engraving technology? Are the benefits enough to justify the investment? Here are some of the best advantages of laser engraving compared to old-fashioned leather crafting:

1. Versatile

The nature of lasers is that they can be customized for just about any application simply by changing its parameters such as its intensity and how quickly it moves along the material while replicating a design. This means that the same laser engraving machine can be used for different types of leather. Whether you’re working with natural leather, synthetic leather, nubuck, or suede, just a single laser engraving machine should be enough for you.

The real beauty of laser engraving is the fact that you can even use the same laser engraving machine that you use for leather for vastly different materials, like metal or wood. This is a level of versatility that other engraving techniques can only aspire to.

2. Design freedom

All it takes for a laser engraving machine to come up with a custom-designed leather piece is a digital design for it to follow. It doesn’t even have to be complex design – any design created from a standard graphics program can be sent to the laser engraving machine using a simple ‘print’ command. Since a laser can have a diameter as small as 0.1 mm., even highly complicated designs can be replicated with professional-grade precision.

3. Quality and consistency

The high energy that the laser emits results in an almost-instant “melting” of the leather material. This is a very precise process that creates perfectly clean and sealed edges that are difficult to achieve with old-fashioned tools. The sealed edges are not prone to fraying and deterioration. Cleaning a finished workpiece also isn’t necessary, which is a huge advantage when working with the types of leather that don’t respond well to cleaning agents.

Laser engraving is a fully automated process so you can expect the same level of quality and precision every single time. This is invaluable in high-volume production and pieces with repeating patterns.

4. Non-contact

Laser engraving is a completely non-contact engraving technique. No tool exerts pressure on the leather, and it doesn’t even need to be secured or clamped down to the platform. This means that handling of the material is lessened, leading to reduced chances of it getting damaged or warping.

5. Fast

Compared to engraving with hand tools, laser engraving can get the job done in a fraction of the time. Even the fact that the items don’t need to be clamped down means that there are fewer steps to be done during processing. You also don’t need to do any tool changes when switching over from one type of leather to the next – all it takes is the loading of pre-set laser parameters.

6. Low maintenance

Another huge benefit of laser engraving being non-contact is that it avoids any wear and tear on the essential tools. Unlike milling and cutting tools, a laser engraving does not need to be repaired or replaced as often. This reduces the cost of maintenance and avoids unnecessary downtime.

Whether for high-volume production or artisanal customization of leather goods, there is no doubt that laser engraving provides a host of benefits in terms of speed, productivity, and quality.

Noteworthy applications of laser engraving leather

It’s probably not necessary to list down all the leather goods that exist in the market – you likely have several lying around in your house. Laser engraving can be used in each one of those. For the sake of discussion, here are a few of the best examples of leather products that have leveraged laser engraving technology to great effect:

1. Leather patches

Leather patches are a great way to provide accents to hats, baseball caps, and jackets. With laser engraving, these leather patches can be cut into intricate shapes and have very detailed designs.

From maps to photorealistic designs, laser engraving can bring new life to the concept of leather patches. Right now, there already are online services that offer customized leather patches that allow for user-submitted designs.

2. Clothing

Laser engraving and laser cutting can be used to create highly intricate dresses, skirts, and various fashion pieces at a level of precision that is not possible with completely manual techniques. Leather jackets with custom laser engravings are also starting to catch on.

3. Office products

What says you’re a professional better than a notebook or desk pad with a custom laser-engraved leather cover? Well, probably a lot of things, but a gorgeous leather piece doesn’t hurt. This is a great way to integrate your sense of style with your professional persona. You can even extend the use of laser engraving to your briefcase or portfolio.

4. Crafts

What better way to show off your creativity than with a piece of laser-engraved leather? From headbands to coasters and guitar straps, laser engraving technology will help ensure that your vision accurately becomes reality. Laser engraving does not require a huge volume to be economical, so even creating one-off pieces isn’t going to be incredibly expensive.

5. Fashion accessories

Leather is typically used as an accent to your fashion getup. While it’s not the main thing, the appropriate pair of leather shoes or a leather handbag will serve to complete your look. To further accentuate your leather accessories, a custom laser-engraved design will give them a bit more personality and uniqueness.

Final thoughts

It’s amazing to see how much new technology is revolutionizing old-fashioned crafts such as leather engraving. More than presenting a new way of doing things, laser engraving eliminates old issues associated with the use of hand tools that are prone to error, can damage the leather piece and are limited in the type of designs they can recreate.

Whether your looking to produce a high volume of leather goods or just one-off designs, laser engraving provides a more reliable and faster alternative to traditional leather engraving methods. If you’re in the leather crafting business, a laser engraving machine is practically necessary to remain competitive.