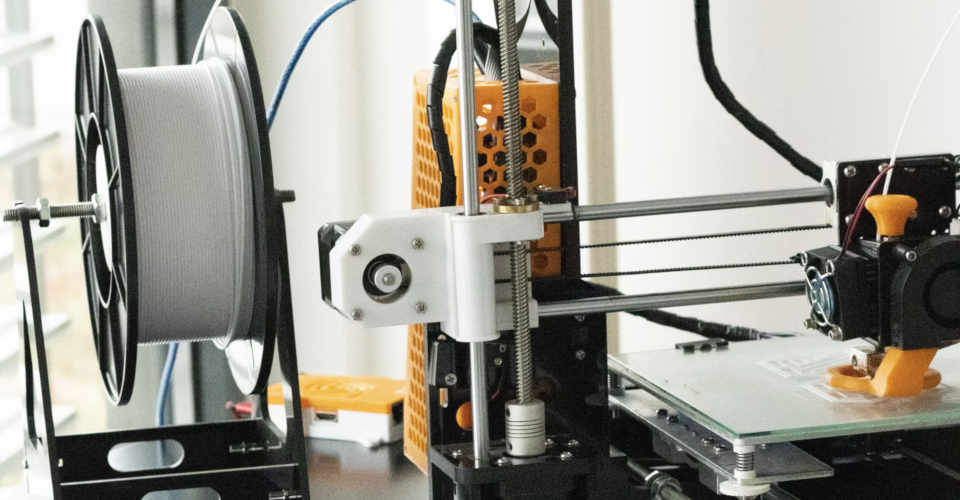

Why Does My PLA Filament Keep on Snapping?

In 3D printing, a filament snapping before or during a printing job can be one of the most frustrating experiences. However, it is something that almost everyone who is into 3D printing has experienced. It also happens more commonly with PLA filament.

PLA filament tends to get brittle and snap because of a reaction with moisture. This can be avoided through proper storage and drying the filament before use. Snapping is also more common when using low-quality PLA filaments.

A PLA filament snapping is practically a universal experience in the 3D printing community. This does not mean that you should just accept it as something inevitable. Let’s look at the reasons for PLA filament snapping and measures to avoid them.

Reaction with moisture

To be clear, all 3D printing filaments are hygroscopic. This means that they readily absorb moisture from their surroundings. This typically results in quality issues during the 3D printing process such as stringing or some layers having small gaps or holes.

With enough exposure to moisture, polymers can react with water in a process called hydrolysis. It is not just PLA that is prone to this. Hydrolysis can happen with just about any other polymer or 3D printing filament. The disadvantage of PLA is that it’s slightly more reactive compared to other filaments like ABS or PETG. This makes PLA more prone to getting brittle because of its low chemical stability.

Unfortunately, hydrolysis is a non-reversible process. If PLA was stored in poor conditions, it will lose its flexibility and elasticity. This characteristic will persist even if PLA were dried in an oven or a filament dryer.

The key to avoiding this is proper storage. Make sure that your PLA filaments are kept in airtight containers or bags. A handful of desiccant for every spool of filament also works wonders in drawing out the moisture from the space inside the container.

Something that most people tend to ignore is the fact that an airtight container will not remain free of moisture forever. Even plastic or foil is permeable to moisture, albeit very slowly. After some time, moisture will infiltrate into an airtight container. For this reason, we recommend using a desiccant that changes color once it absorbs enough moisture. This provides a good visual indicator that the desiccant needs to be replaced, as its moisture absorption capacity has been maximized.

Poor-quality PLA filament

Sometimes, it really is just the filament. No amount of proper storage or careful handling can make up for the deficiencies of a filament that was made poorly. Poor quality parameters can manifest as microscopic cracks on the filament or as reduced flexibility of the polymer material. This will make the filament more likely to snap with some mechanical stress.

Filament that has been stored for a long time may also be more susceptible to cracking. Keep in mind that 3D printing filament is typically packed in airtight plastic bags, which we have established is very slightly permeable to moisture. It will probably take months before this effect becomes significant, but it can happen.

To avoid such issues, it’s best to buy your filament from reputable brands or those that have been heavily used by the 3D printing community. There is a handful of them out there, so finding one that is available for you won’t exactly be difficult.

Take note that there are certain additives that naturally reduce the flexibility of PLA. Those that are used for compound filament such as metal powder, wood shavings, or carbon fibers tend to produce this effect. Be extra careful about handling these filaments and making sure that they are stored in a moisture-free environment.

Excess mechanical stress

Even for a naturally flexible material like PLA, snapping can happen when it experiences too much mechanical stress. This emphasizes the importance of gentle handling. Keep in mind that the filament is being straightened in the extruder from its curved orientation in the spool. You will want to make the transition from the spool to the extruder as gradual as possible.

If you’re buying your filament from a reputable brand, then this should not be as much of a problem. Just to play it safe, try bending a small segment of every new PLA filament once you have purchased it. A brand-new PLA filament should not snap easily if it’s well-made.

Final thoughts

Snapping filaments is quite common in 3D printing, but it more frequently happens with PLA. Compared to other 3D printing filaments, PLA has low chemical stability making it more prone to hydrolysis when exposed to excess moisture.

With this knowledge in mind, proper storage should be the key to making sure that your PLA filaments don’t break apart prematurely. It would also help if you buy your PLA filaments only from the more well-known brands that have good track record when it comes to quality.