Wood Filament: Properties, How to Use Them, and Best Brands

We remember a time when making a custom piece made of wood involved using traditional wood-working tools: hammers, chisels, saws, and more. While there is nothing wrong with using good, old-fashioned elbow grease, we often prefer the more modern (and easier) method nowadays. Wood filaments are another example of composite material filaments that you can use to make custom 3D prints that do not look and feel like standard plastic. If this is something you are curious about, then read on as we discuss everything that you need to know about wood filaments.

What are wood filaments?

Similar to other composite filaments, wood filaments are made from standard PLA infused with very finely powdered wood materials. The material fused with PLA may be wood dust, cork, bamboo, or other powdered wood derivatives. Most wood filaments in the market today consist of around 60 to 70% PLA and 30 to 40% wood fibers. This allows you to use standard desktop 3D printers to make prints that have a distinctly wood-like finish.

What are the benefits of using wood filaments?

The number one reason for using wood filaments is the superior aesthetics that it can deliver, especially compared to standard plastic filaments. Prints made from wood filaments have a finish that comes very close to the naturally grainy look of real wood. The layer lines that normally appear in 3D prints can be sanded very lightly and will end up blending very well with the overall grainy aesthetic that you may be trying to achieve. All in all, wood filaments give you prints with a wood finish without having to go through all the complexity and having all the skills (not to mention the number of tools) needed for old-fashioned woodworking.

Wood filaments are relatively easy to work with as they have a very low tendency to warp or shrink. This allows you maximize cooling while printing, allowing for a stronger build. Since the matrix for the fine-grained wood materials is standard PLA, most printer settings that work well with PLA should work well enough for wood filaments. Finally, wood filaments are significantly less abrasive compared to other composite materials such as metal or carbon fiber. That being said, there will still be some degree of wear and tear on your nozzle but it will be less pronounced than if you were using more abrasive composite filaments.

Most wood filaments emit this pleasant wood-like smell, especially during the printing process. However, the filaments are still largely PLA-based, so maybe don’t go around sniffing the fumes off of the print no matter how good the smell is. The final print does sort of inherit this pleasant smell, although to a much less degree. In any case, being able to make a nice-smelling print is another dimension of wood filaments that none of the other typical filaments can provide.

Unlike other composite materials, wood is very biodegradable. The combination of wood and PLA results in a composite filament that is largely biodegradable. This means that anything you print with your wood filament can be broken down in a compost or landfill. We have always been supportive of developments that will make 3D printing more environment-friendly, so this is a huge plus in our book.

How do you use wood filaments?

There are quite a number of wood filaments in the market today, so there is some variety in terms of both the wood-to-plastic mixing ratio and the wood material infused into the PLA. Naturally, this means that printer settings will have to be tweaked depending on the wood filament brand that you are using. It is always best to start out by following the instructions included in your filament, or by asking the manufacturer for specific details on printer settings.

Most wood filaments print well within a temperature of 170 to 220 °C. Yes, this is quite a broad range so you are going to have to experiment for a bit to get the best temperature. We recommend starting at the higher settings (around 210 to 220 °C) so there will be less chances of the filament causing some jamming in your nozzle. Printing at too high temperatures may result in some stringing in your print, but cleaning these up during post-processing is much easier than having to clean out your nozzle because of jams.

Wood filaments generally have good layer adhesion, so you can print well at high speeds. We have gotten good results with printing speed settings of 65 to 75 mm/s, but you can try starting at around 50mm/s and work your way up.

A heated bed is not necessary for printing wood filaments, but you may use one with a setting of 45 to 60 °C. A layer of standard blue painters’ tape performs excellently for bed adhesion in an unheated bed. If you are using a heated bed, we find that a layer of applied glue sticks works best.

As we have mentioned, warping and shrinking is not much of a concern when working with wood filaments, so we recommend using a cooling fan at maximum settings. As the material is quite heavy, providing rapid cooling will allow your print to solidify and strengthen faster.

Retractions are kind of a weak area for wood filaments, as with other composite materials. The presence of solid particles in the PLA matrix makes it hard for the nozzle to maintain suction while retracting, which may result in a lot of unnecessary stringing. We recommend using a design that requires minimal retraction. You may also use functions that reduce retractions, which are available in some 3D printing software.

The wood particles in wood filaments react with heat, which gives it the unique property of changing colors when exposed to higher temperatures. Generally, experience has showed that wood filaments make prints with darker and richer colors when the temperature is increased.

Leaving your wood print as it was printed is perfectly fine, but it can look a bit bland. To really make that wooden look pop out, you are going to have to do some finishing. There are a number of ways to do this. Most people start out by sanding the print using a fine-grit sandpaper to get a smooth and consistent finish. After this, the print can be painted with a number of wood finishing compounds such as varnish, wood lacquer, or wood finishing oil. Not only do these compounds give the print a darker and richer color, but they also help in keeping the moisture out and preserving the print.

What are the limitations of wood filaments?

Even though prints made from wood filaments look so much like wood, there remains the fact that it is not wood. In terms of strength and durability, it is probably much more similar to PLA than real wood. It is an inflexible material, and this brittleness might actually make it a little weaker than PLA. Although they can make excellent design and display pieces, we do not suggest using your wood prints to support heavy loads.

As with other composite filaments, wood filaments are brittle and can easily break if the filament path from the spool to the extruder is not as smooth as possible. We suggest eliminating sharp turns in the filament path when working with wood filaments.

Although the process of printing with wood filaments is relatively simple, a certain characteristic of the wood kind of throws a wrench into the works. Unlike other materials used in composite filaments such as metals or carbon fiber, wood can burn when exposed to high temperatures. This is why it is not a good idea to leave wood filament on the hot end for a long time. Doing so will likely end up clogging your nozzle. Make sure to always push out leftover wood filament from your nozzle after printing. If you have to stop at any point during printing, it is recommended to pull the filament out of the hot end nozzle.

We have mentioned that wood particles are not as abrasive as metals or carbon fiber, but they can still cause wear and tear when using standard brass nozzles. Using a larger-sized nozzle can reduce abrasion between nozzle and filament, and also lessen the chances of clogging in the nozzle. We find that nozzle sizes of 0.5mm and higher work best with wood filaments.

Wood filaments are a bit more expensive that the standard plastic filaments, so playing around with them can set you back a few more bucks. They are not so expensive to be prohibitive, but you are going to feel bad if you ruin your wood print.

What are the best brands of wood filaments available today?

Wood filaments are extremely popular, so there are a good number of wood filaments available in the market. We highlight below the most popular and highest rated wood filaments that we recommend.

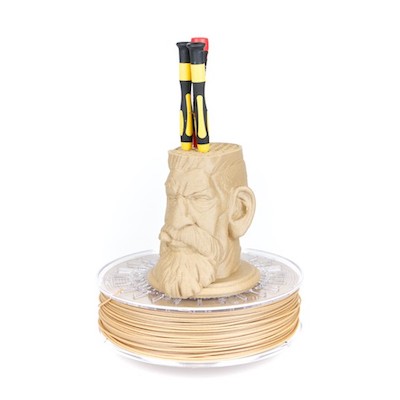

ColorFabb has a very interesting set of wood filaments that come in 3 varieties: WoodFill, BambooFill, and CorkFill. As the names imply, these filaments are made from different wood-based materials: wood, bamboo, and cork, respectively. Each of these filaments produce a characteristic look and feel in the prints that mimic the source material. The filaments are available in 1.75mm and 2.85mm diameters, and are sold in spool sizes of either 600g, 650g, or 750 g.

The wood filament from HATCHBOX is probably one of the most popular wood filament products in the market today. It is PLA-based and made from recycled wood. HATCHBOX promises that this wood filament is easy to use, with minimal warping and no need for a heated bed. They are only available in 1.75mm and are only sold in 1 kg spools.

TIANSE sells a wood filament that is slightly more affordable but is also quite popular and has received good reviews. It is also PLA-based with 25 to 30% wood content. It does run into problems when used with smaller sized nozzles, but that is par for the course with wood filaments. This filament is available 1.75 mm diameter and is only sold in 1 kg spools.

MG Chemicals also sells a wood filament that has received favorable feedback. It is slightly more expensive than the previous entry but performs well and delivers high quality prints. The filament is available in 1.755 mm diameter and is sold in smaller 0.5 kg spools. This is a good choice for those who are just starting out with wood filaments and want to try them out first.

The wood filament from the reliable GizmoDorks brand is another highly rated product, albeit a bit more expensive. It comes in 1.75mm diameter and is can be purchased in either 1 kg or 200 g spools.

The wood filament from SainSmart comes in a rich, dark brown color which sets it apart from the other entries in this product line. This is a 3.00 mm diameter filament which is sold in 1 kg spools.

The final word

| Material | Wood filaments |

| Properties | – Wood-like appearance that can be sanded and finished for further enhancement – Wood-like smell during printing and in the final product – Inflexible and brittle – 100% biodegradable |

| Applications | – Display and design items – Trinkets and jewelry |

| Recommended printing temperature | 170 to 220 °C |

| Recommended bed temperature | Heated bed not necessary; a temperature of 45 to 60 °C is recommended if using heated bed |

| Printing speed | 65 to 75 mm/s |

| Bed adhesion | Blue painters’ tape or glue stick |

| Cooling | Cooling fan at maximum setting |

In the realm of composite filaments, wood filaments are probably the easiest to work with. They are less abrasive, a little lighter, and have very little tendency to warp or shrink. They have a particularly nice smell, and finish very nicely and easily. Finishing wood prints can be quite a joy and might just bring out the artisan in you.

Wood prints will not probably fool anyone when it comes to durability and weight, but they make very nice set pieces for your wooden shelf, wooden door, or inside a wooden cottage. There is no need for chisels and hammers – just your trusty 3D printer. We recommend taking wooden filaments out for a spin for a truly unique 3D printing experience.