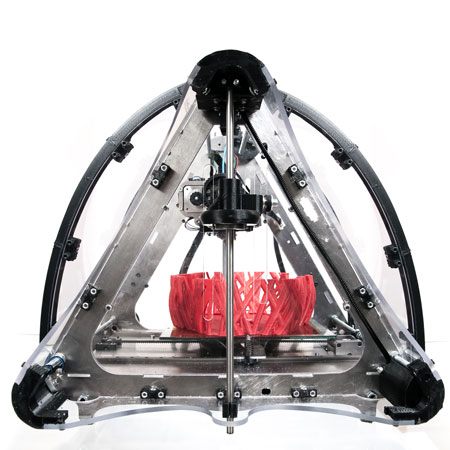

ZMorph 3D Printer Combines 3D Printing & Milling

There seems to be an influx of new personal fabricators that combine 3D printing and traditional mill machining to create the ultimate desktop manufacturing device. ZMorph 3D has added another personal fabricator to that list with the ZMorph that is based on the RepRap Prusa Mendel machine.

They have added a number of improvements and features to the RepRap design including a chamber that keeps the internal temperature high, which prevents plastic from warping and a large 235x230x165mm build area. A stiffer body allows for higher print speeds.

Through the use of exchangeable toolheads including a extruder for 3D printing, CNC mill and an interesting chocolate extruder, users will be able to print in ABS, PLA, Nylon, polycarbonate, ceramics and also chocolate. Eventually ZMorph is looking to release a double extruder for multicolour/material printing or support material.

Specs:

- Construction: aluminium 6mm

- Working area of 235x235x165mm

- Nozzle: interchangeable hot-ends : 0.38mm, 0.5mm

- Max travel speed 500mm/s, print speed 60-100mm/s (varying depending on layer height and nozzle size)

- Min. layer height: 0.1 (ABS), 0.05 or less (PLA)

- Heated bed: glass 5mm, kapton heater 200W, standard temp 120 degrees.

- External dimensions: 530x555x480 mm

http://www.youtube.com/watch?v=jkeuwwjRSwc

ZMorph 3D printers were used in the construction of a 3D printed sculpture called BIOSTAGOG, which is based in Warsaw. The sculpture is currently sitting in the currently sitting headquaters of Platige Image Studio. It took five ZMorph 3D printers three months to create the 800 parts needed for the interactive display.Y

The ZMorph 3D printer is available for purchase at €1250.

https://www.youtube.com/watch?v=ANQ2o9hLLi4

https://vimeo.com/61975101