Why 3D Printing is Important

Over the decades, technology has gained popularity and has shaped the bug and little things that we are enjoying today. Below, we will be delving more into the value and impact of 3D printing technology in our day-to-day lives and how it can affect our way of living in the future.

Potential to Transform Industries

Medicine

Staying fit and healthy has been a top priority by many, which is why experts continue to find ways to improve the current health care system. 3D printing has revolutionized our health care from faster medical tools and equipment manufacture to the fabrication of patient-specific prosthetics.

But are these enough? Experts are continuously making ways on how we can use 3D printing. Here are 3D technology breakthroughs we might be seeing in the future:

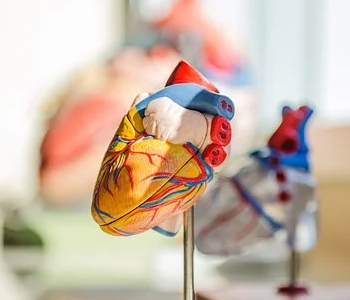

3D Printed Organs

Healing wounds with laser beams and creating replacements for amputated body parts is a concept we all see and hear from science fiction. We are not far off from this turning into reality. A survey conducted by Verdict Medical Devices in 2020 showed that 25% of its respondents believe that 3D printed organs will replace the need for donor organs within the next decade or so.

The demand for organ transplants is on the rise every year. Sadly, there is a shortage of donor organs worldwide, so professionals are deeply looking at bioprinting as the answer to this medical situation.

Bioprinting is an additive manufacturing technology that uses cells, proteins, and biomaterials as raw materials. Over the past years, studies on bioprinting have increased, and its technology is getting better each day.

Although researchers have already successfully generated various functional human tissues, they are still miniature and comparatively simple. Likewise, there is still the need to overcome several technological, regulatory, and ethical barriers before fully applying them clinically.

As of now, 3D-printed organs are primarily utilized for research and development purposes. However, with the many great things our scientists discover, bio-printed organs are something that we will see in the future.

Patient-centric Drugs

The pharmaceutical industry has adopted 3D technology in producing drugs and therapies for quite some time already. Medication adherence is a significant concern for public health since it is associated with the overall health outcome. Drugs were initially developed with the idea that each pretty much works the same way in every patient. On the contrary, this idea isn’t entirely accurate.

Even in the 21st century, many pharmaceutical companies are still using the traditional processes in making drugs. These drugs, however, are often made as a one-size-fits-all and can be dose inflexible. This poses significant challenges for those patient groups – particularly pediatrics and geriatrics – that need tailored quantities.

For instance, children and youths come in different body masses and require diverse dosages of medicine. Since drugs mainly come in standard dosages, patients need to cut their pills, assuming that gives them the prescribed amount of medication. Albeit a widespread practice, pill splitting is not recommended since significant dose deviation or weight losses may occur.

Furthermore, some pills deteriorate after splitting, which makes them infective. Conversely, there are some pills designed as time-release or extended-release medications. These should never be crushed or broken since the dose might come out much higher and faster.

To eliminate pill splitting practice, pharmaceuticals have come up with patient-centric drugs. These are medicines specifically designed for a particular target patient population to give them the most effective treatment. Pharmaceutical companies are using 3D technology to create these personalized medicines.

The medical industry is looking into having 3D printers in hospitals and maybe even in drug stores to provide medications manufactured explicitly for each patient. By doing so, individuals will get the optimum medication and therapy that they need. Although the technology still needs further research and improvement before introducing it to the public.

Automotive Industry

Additive manufacturing has played a vital part in the production processes for automobiles. The automotive industry initially used 3D printing for prototyping but has progressed to fabricating 3D printed car parts in recent years.

With 3D technology, engineers can try multiple design options during the stages of new model development. Making changes in designs is also made easier, which helps carmakers stay up to date with market demand and be ahead of the field.

In the time being, engineers from the automotive industry are continuously finding ways to maximize the application of 3D printing in automaking, such as providing customer-specific cars to fully 3D-printed ones.

Space Exploration

According to Tracie Prater, materials Engineers at Marshall Space Flight Center, NASA would send around 7,000 pounds of spare parts to the International Space Station (ISS) each year. When you are 200 miles away from Earth, you want to make sure that you have everything you need. However, a vast majority of spare parts sent are never used.

Instead of hoarding spares, NASA maintains 3D scanners and printers at the ISS for astronauts to fabricate tools, spare parts, and other necessary supplies. This investment has reduced the cost of space exploration and lightens the load of space crafts and stations.

In the time being, 3D printers are mainly used by space explorers to produce emergency tools and spares. However, they are looking into using the technology to establish outposts on the moon and Mars while using lunar and Martian materials.

Importance of 3D Printing in Industry

Manufacturing

Throughout the years, the manufacturing industry has been looking at new and innovative ways to improve its production processes. Although mostly fully mechanized, traditional techniques would still require different tools and pieces of machinery when creating a new part.

3D printing has been making quite a buzz because of its precise manufacturing process and its ability to fabricate parts and products with only a single machine. Assembling the components can also be done in a single stage, which significantly helps cut down production time and improve production efficiency. As computer-operated machines, their standards and processes are more controlled, minimizing the risk of errors in the production line.

Retail

Developing new ideas is very important in the retail sector to give consumers something to look forward to in the future. 3D technology allows manufacturers to come up with new designs by mixing traditional methods and 3D printing.

If you are familiar with the Ministry of Supply clothing brand, you must be aware of the several breakthroughs they have made in the retail industry. But have you heard of their most recent high-tech approach to making clothes? Customers can now have whatever clothing they want personally customized and 3D printed within 90 minutes in their Boston-based retail outlet.

Aside from the Ministry of Supply, the retail industry has also been reaping benefits from 3D printing for some time.

The technology helps speed up production and allows custom-made product designs. It reduces the costs and inventory waste, as well. Another importance of 3D printing in the retail sector is the possibility of fabricating spare parts to fix products currently available in the market and preserve products that were already phased out.

For instance, Whirlpool, to combat obsolescence, has digitized its part catalog. Porshe also has a Classic Division dedicated to the brand’s classic and rare vehicles. This division utilizes 3D printing to produce spare parts for their rare cars since original parts are not made regularly.

Furthermore, the retail sector is benefiting from 3D printing spare parts by cutting costs in inventory. Before, companies needed ample space to store their spares and pay people to keep up with the stock. However, with additive manufacturing, inventory costs are cut down since spares can be easily fabricated with 3D printers.

In-house printing through 3D technology has also affected the supply chain since manufacturers have saved time and money in their operations. Since it reduces the complexity of production, the turnover of retail products in the market has improved.

Education

Humans tend to retain information better if we get to experience what we are learning personally. That is why schools would often arrange field trips for their students. But what if field trips are not possible?

For the past years, more and more schools are investing in 3D printers, allowing educators to bring out objects from the computer screen and into the physical world. This gives students an active experience and a better grasp of the subject matter without leaving the safety of the school grounds.

Aside from giving hands-on experience to learners, 3D printing also provide access to knowledge and learning opportunities that were once unavailable. For example, during science class back in the old days, you had to peek into microscopes to get a real vision of what a cell looks like.

Then you had to draw what we saw on paper for future references. Aside from this practice being time-consuming –and not to mention eye-straining – drawings may come out as inaccurate despite how hard you work on them. Students these days have it easier since their teachers can provide them with 3D printed, large-scaled models of the cell to study.

Advantages of 3D Printing

Flexible Design

One of the 3D printing’s greatest assets is its ability to accurately capture even the most delicate details of the most intricate design. Compared to traditional methods, designing with 3D printing is almost limitless. Designs once considered impossible is now available.

Unlike the conventional manufacturing practice, 3D printers can also include different materials into a single fabricated object. This gives the end product more of an array of colors and textures.

Another factor that hinders the design flexibility of artists and engineers is the size of the object. Scales and sizes have been a great challenge when it comes to executing designs. With 3D printing, scaling is no longer an obstacle for manufacturers. They can now produce objects according to their preferred sizes without compromising the final output.

Rapid Prototyping

3D technology is a game-changer when making prototypes because of its speed and broadened design possibilities. For years, the majority of market players are using this technology for prototyping their products. But as the value of 3D printers continues to drop in the market, smaller businesses have also started investing in one for prototyping purposes.

Before 3D printing became a thing in the manufacturing industry, many businesses had to outsource the fabrication of prototypes to third-party shops. Under ideal situations, the turnaround time for conventional prototyping would take at least a week. With 3D printers, it only takes as little as 30 minutes to several days.

Another practical advantage of using 3D technology is that most 3D printers are compatible with a wide range of raw materials. When making prototypes, this feature allows creators to experiment on different materials to determine which is most suited for the fabrication of a part or product.

Print on Demand

As stated earlier, companies before 3D technology have been spending a lot on the inventory of their products and their spare parts. Print on Demand is an advantage for the manufacturing and retail industries since it helps companies save a lot of resources, unlike traditional manufacturing processes.

Today, companies would have a virtual library of portfolios for the 3D design files for the items they are fabricating; hence, keeping a large inventory is no longer necessary. Whenever needed, all they have to do is look for the specific file and 3D print quickly. They can also edit their existing designs at a meager cost to further improve their products.

Lightweight Parts

Lightweight metal parts are something high-performance industries, such as automotive and aerospace, consider the holy grail. Fabricating using lightweight materials reduces production costs and optimizes fuel consumption efficiency while meeting the given regulatory standards.

It is hard to achieve metal lightweight using traditional manufacturing practices. 3D printing has become the lightweight metal solution of engineers since the technology allows them to explore designs and raw materials to make products as light as possible without compromising their efficiency.

Hallowing is a prominent 3D printing design feature. As its name suggests, it involves building an algorithm wherein the inner material part of the materials is removed. Not only is it an excellent technique to create a lightweight object, but it is also an excellent way to save materials.

The most robust lightweight material ever made is only 5% the density of steel but ten times stronger. A team of MIT researchers who then published their findings in Science Advances created it. The scientists used graphene as raw material and 3D printers to try different designs before settling on the strongest shape. The geometrical structure of the 3D graphene is so complex that it could only be done using three-dimensional technology.

Fast Design and Production

Prototyping is critical in product development. Often, manufacturing companies would outsource this process from third-party shops and have to wait for the 3D sample before testing it for any corrections. Once the design is complete, it is time to mass-produce it. In the past, companies use traditional manufacturing methods that include different processes and utilize various tools and types of machinery.

With 3D printing technology, company designers can finalize prototypes in-house in a short time. Many players in the manufacturing industry have already adopted a 3D printing assembly line and were able to reduce turnaround of design conceptualization and production of goods successfully.

Minimal Waste

The traditional way of fabricating products would start with a block of raw material and then use different tools and machinery to remove chunks of it until the final part comes out. This method, also known as subtractive manufacturing, generates a lot of waste. Studies show that such manufacturing practices can produce waste material as high as 95%.

3D printing, on the other hand, fabricates products by sintering raw materials where it is only necessary. Unsintered materials maybe even reused, which means waste produced is very minimal.

Cost-Effective

Manufacturers invest a lot of time and money in traditional prototyping and manufacturing practices. Since 3D printing is computer-controlled and gives developers a preview of the final product before mass production, companies eliminate mistakes or errors during prototyping. Plus, they can save costs associated with the use of different machines.

In addition, physical inventory is not required with 3D technology since manufacturers can store their designs “in the cloud” and print them when there is a demand for a particular object. These three-dimensional designs can also be sent across the globe in digital form and printed locally. As a result, companies can save time and expenses for shipping and inventory.

3D Printing: Enhanced Competitive Advantage

Statistics show that 71% of manufacturers have already embraced 3D printing in their production. Correspondingly, 93% of these businesses claimed to gain competitive advantages over companies that have not adopted this technology. Here are five ways how 3D printing technology give businesses a competitive edge against their rivals:

Less Equipment

Compared to conventional manufacturing machines, 3D printers occupy a smaller space since it is a single-process machine that can be easily adjusted to produce different parts and objects.

Minimal Manpower

Compared to traditional manufacturing plants, operating 3D printers is not as labor-intensive since they are primarily computer-controlled and come with smart technology. It involves a straightforward process.

Superior Product Quality

Customers these days would rather pay more for top-notch products than pay less for substandard ones. Companies today are ensured that the products they offer to their clients are of top quality. This is because 3D printers provide exact replicas of the final product design. The successive manufacturing process of 3D printing technology also makes monitoring for errors possible, therefore reducing the risk of getting faulty products.

Speed and Efficiency

Fabricating objects are now faster and more efficient, thanks to 3D printing technology. Since the process is digitally operated, manufacturers can design, produce, and test their products continuously with minimal faults in the production line. As a result, companies are to release their final products in the market sooner than usual.

Cuts down Overhead Cost

Less equipment means companies can save on expenses related to space, as well as operation and maintenance. In addition, 3D printing is a type of additive manufacturing, which maximizes the use of raw materials.

Final Thoughts

Despite being a relatively young technology, additive manufacturing –mainly 3D printing-practically changes the way we live. It has proven itself to be helpful not just for manufacturing purposes but also for research and education. With the endless potential and possibilities with 3D technology, what used to be science fiction for us might be our reality in the future.

Regardless of its roles in different industries, its ability to rapidly turnaround times when it comes to conceptualizing and turning that concept into something real and tangible has brought many positive impacts.

Since you can now easily share through digital networking, more communities – even those from third-world countries and far-flung areas – can have better access to technologies once unavailable to them.

But despite the endless potential and possibilities, it can offer, we still have to consider the number of roadblocks that should be tackled. You have to keep in mind that where there are pros, there will also be cons.

It’s just a matter of determining which one weighs more. After all, whatever issues and concerns you have with 3D printing will eventually be addressed as researchers continue to learn and understand the technology.

In the end, the 3D printing industry will continue to rise and bring more benefits to our economy and society. It is now time for companies who are not yet into the technology to change how they innovate and design by investing in 3D printers.