ABS Vs PLA Shootout

3D printer users have an ever growing catalogue of materials to choose from. However there are two thermoplastics that are the staple of 3D printable materials: ABS and PLA. Both thermoplastics are widely used in 3D printing and many other manufacturing processes, but which one is for you?

We’ll start by saying that you should stick to your 3D printer’s manufacturer’s guidelines when it comes to choosing a material. Use the materials your printer manufacturer recommends, unless you have some experience with extruders or 3D printer design.

ABS overview

Acrylonitrile butadiene styrene (ABS) plastic is made from oil-based resources and is known for its impact resistance and toughness. ABS can also be modified to improve its mechanical properties and is generally useful for parts that will not be used in environments lower than -20 degrees Celsius or in excess of 80 degrees Celsius. Compared to PLA, ABS has a much higher melting temperature. It is used in items from golf club heads (due to its good shock absorbance) to automotive trim components and pipe systems.

PLA overview

Polylactic acid (PLA) plastic is created from renewable resources, such as corn starch, tapioca roots or sugarcane. It is biodegradable and is widely used in packaging for items like food products. PLA is more brittle than ABS and due to its biodegradability PLA components have a shorter lifespan than ABS when subjected to harsher conditions.

Printing with ABS

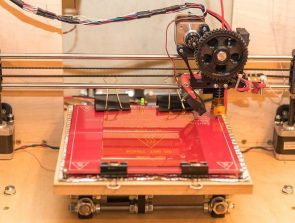

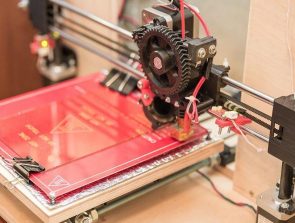

Due to its higher melting point, ABS has to be printed at a higher temperature of around 190 to 200 degrees Celsius (although nozzle temperature is generally quite a bit more). It also needs to be printed onto a heated build platform. Printing on an unheated surface will cause ABS plastic to deform and warp, which could either lead to the print coming off the print bed or unsatisfactory print quality. Print bed temperatures for ABS plastic generally range from 90 to 100 degrees Celsius or in some cases In excess of 100 degrees. Ensuring the print bed is smooth is also important and various solutions are sometimes applied beforehand to the print surface. These solutions could include a mixture of ABS and Acetone, or hairspray.

Printing with PLA

PLA is slightly easier to print with than ABS due to its lower print temperature and its ability to print on and stick onto an unheated print platform. Despite not needing a heated print bed, many PLA users still print at a print bed temperature of around 50 to 60 degrees Celsius. They also use “blue painters tape” applied to the surface of the print bed. Additionally, PLA filament can print at higher speeds; however that depends on the printer used and what the print job is.

https://www.youtube.com/watch?v=O6boD0aCWok

Accuracy

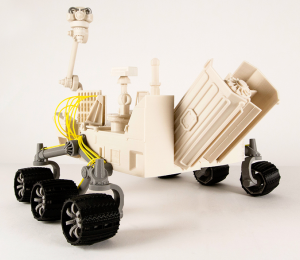

Both ABS and PLA can produce dimensionally accurate parts and most people would have trouble distinguishing the better print. However, there are a few differences worth noting.

ABS – Like stated above, ABS’s biggest disadvantage when it comes to print quality is its tendency to curl and warp at the bottom, or even sometimes in the middle of the print. ABS also has more trouble when it comes to finer details like sharp corners, which will often be printed with a slight rounded edge.

To improve ABS prints, many people use a method of bathing their prints in an Acetone bath or Acetone vapour. This smooth’s out the print lines and gives a glossy, shiny appearance.

PLA – Compared to ABS, PLA exhibits much less print warping. Because it undergoes more of a phase-change than ABS, it can also print much finer details. Active cooling enables PLA to print much sharper corners without the risk of curling, warping and cracking. PLA can also be printer at a higher flow rate, which leads to stronger over layer bonds. ABS components are still stronger due to the plastic’s mechanical properties.

Fumes

Anybody who’s been around 3D printers, especially those printing with ABS know there’s a distinct plastic smell that can be offensive to the nose. 3D printing fumes can be a huge potential turn off for those wanting to purchase a 3D printer and many are wondering how dangerous the plastic particles actually are. Ensuring your printer is in a well-ventilated area and the filament used is free of any contaminants will reduce the smell considerably. Printing at the correct temperature will also reduce the amount of fumes released into the surrounding environment.

ABS – plastic is made up of three main components which release tiny particles into the environment when heated. These particles can be potentially harmful to those breathing them in. The main components are:

- Acrylonitrile is a “Reasonably Anticipated to be a Human Carcinogen”.

- Butadiene is a “Known Carcinogen”.

- Styrene is a “Reasonably Anticipated to be a Human Carcinogen”.

PLA – Because PLA is made from natural materials such corn it does not release the same sort of toxic smell that ABS emits. PLA gives off a smell similar to semi-sweet cooking oil, although it probably won’t remind you of home cooking though. Much like ABS, PLA does release ultrafine particles into the local environment which can be harmful to humans; however they are not nearly as damaging as ABS particles.

For those who are interested in a more in-depth explanation of the fumes produced by ABS and PLA, Science Direct published a report that details some of the dangers of ultrafine particles produced by 3D printing.

Storage

Both ABS and PLA absorb moisture from the air if they are not stored properly. However your filament is not going to be ruined in a couple of days and moisture can be removed by drying it with the likes of a food dehydrator or oven. Preventing moisture absorption can be achieved by placing you filament in a sealed container or bag.

ABS – Symptoms of moisture laden ABS include bubbles on the filament and erratic extrusion. Moisture can reduce the print quality, print speed, strength and can even damage or clog the nozzle.

PLA – PLA exhibits similar characteristics to ABS when moisture laden. However the filament can also become discoloured and the polymer bonds can break down when the plastic is exposed to water at high temperatures. While drying can be beneficial to reduce the moisture content of PLA filament, it can alter the crystalline structure of the PLA, leading to different print characteristics.

Wrap-up

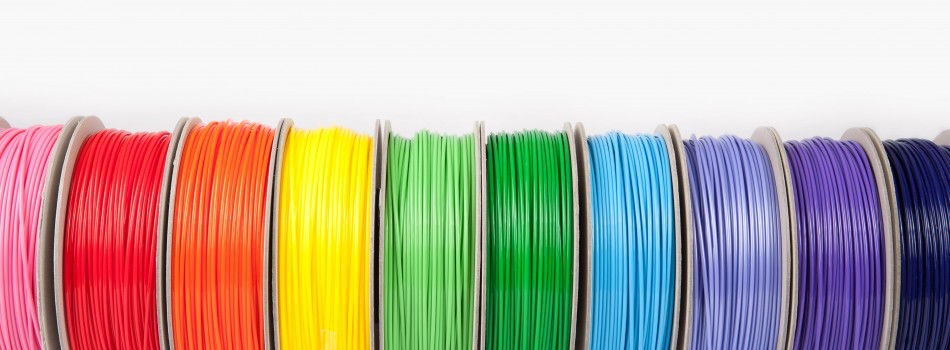

In conclusion there is really no winner when it comes to the debate of PLA vs ABS plastics. Those looking for more durable, weather resistant components will probably find ABS more beneficially. PLA will suit those who are looking to create smoother, higher quality prints straight from the printer and don’t want to put up with ABS plastic’s terrible toxic smell. Additionally, PLA also seems to come in more varieties and colours which could be a selling point to some.

Source’s: Science Direct, Thingiverse, Wikipedia