Latest 3D Printing Stories

- Top 10 Best 3D Printed Accessories for PlayStation 5

The PlayStation 5 is the hottest gaming console today. With its lightning-fast …

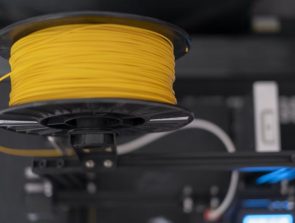

- Should You Print with PETG Instead of PLA?

PLA has long been the standard default filament for casual 3D printing. …

- How to Make Money from 3D Modeling

When you develop a cool skill like 3D modeling, it’s certainly an …

- How to Set the Prices of Your 3D Prints

While 3D printing for fun has become very common, most people buying …

- AMF File Format – Should You Use It For 3D Printing?

The 3D printing industry is quite unique in that it suffers from …

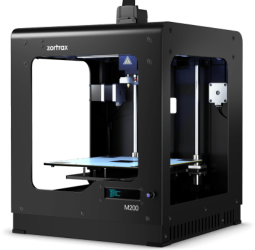

- The Creality CR-10 Smart 3D Printer – Is It Smart Enough?

In recent months, there has been a trend of 3D printers being …

- Top 10 Best 3D Printed Articulated Figures

3D printing is capable of producing geometries that would otherwise have been …

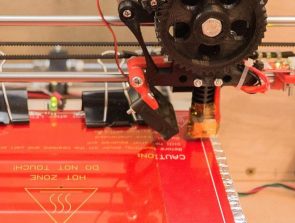

- 3D Printer Z-Offset: What It Is and How to Use It

The Z-offset setting of your 3D printer is the distance between the …

- What is the Best Glue to Use for 3D Printing?

There are many instances in 3D printing where you have to glue …

- 3D Printing Ideas for the Summer of 2022

The summer of 2022 is upon us, and it is once again …